An in-situ test system for magnetoelectric stress coupling of nitride light-emitting diodes

A light-emitting diode, in-situ testing technology, applied in the direction of single semiconductor device testing, etc., can solve the problem of lack of real-time measurement and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

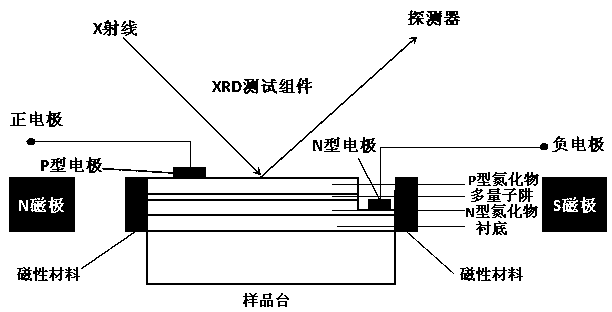

[0016] The structure of an in-situ test system for magnetoelectric stress coupling of nitride light-emitting diodes proposed in this embodiment is as follows: figure 1 shown. First, the nitride light-emitting diode includes a substrate, an N-type nitride, a multiple quantum well, a P-type nitride, a P-type electrode, and an N-type electrode. Electrode and negative electrode, through the current; secondly, the side wall is plated with a thickness of about 100nm Fe 3 o 4 The nitride light-emitting diodes of magnetic materials are placed on the sample stage of the XRD test components (including X-rays, detectors, etc.), and then the electromagnet magnetic field is set on both sides of the nitride light-emitting diodes as a magnetic field generating device, that is, when the nitride emits light A magnetic field of N / S magnetic poles is applied on both sides of the diode. Using the principle of X-ray diffraction, X-rays are irradiated on the nitride light-emitting diodes. The ω-2...

Embodiment 2

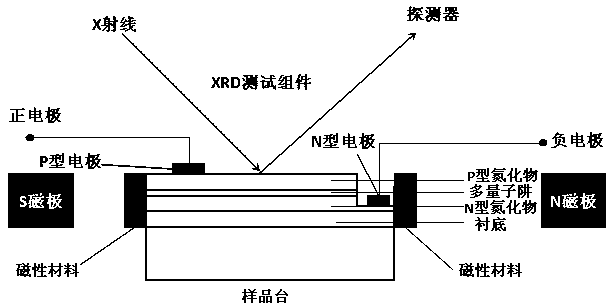

[0018] The difference from Embodiment 1 is that this embodiment changes the magnetic field by changing the magnetic pole of the magnetic field, transforming the original N magnetic pole into an S magnetic pole, and transforming the original S magnetic pole into an N magnetic pole to change the direction of the magnetic field. By changing the magnitude and direction of the magnetic field under a certain electric field condition, the obtained The direction and size of the electric field and magnetic field corresponding to the optimal stress and luminous efficiency of the nitride light-emitting diode can regulate the stress change of the nitride, thereby improving the luminous efficiency of the light-emitting diode, so that the nitride light-emitting diode can achieve the highest luminous efficiency output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com