Raman scattering method for measuring GaN thermal expansion coefficient

A thermal expansion coefficient and scatterometer technology, which is applied in the direction of material thermal expansion coefficient, Raman scattering, material excitation analysis, etc., can solve the problems of unfavorable influence of measurement results, difficult to measure accurately, and small thermal expansion coefficient of GaN, so as to avoid formula derivation and Mathematical calculations, clear physical meaning, simple formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

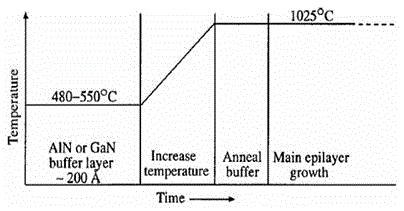

[0040] A Raman scattering method for GaN thermal expansion coefficient measurement comprises the following steps:

[0041] Step 1, sampling and cleaning the GaN epitaxial film sample.

[0042] Use a diamond glass knife to slice the grown GaN film sample with a diameter of 2 inches to make a sample with a size of about 1cm×1cm. The GaN epitaxial layer film is cleaned on the surface, and the a-plane GaN epitaxial layer The film is placed in a vacuum of 5.0×10 -3 In the mbar CVD furnace chamber, nitrogen gas with a flow rate of 60-100 liters per minute is introduced at room temperature to remove scratches and surface attachments on the surface of the film;

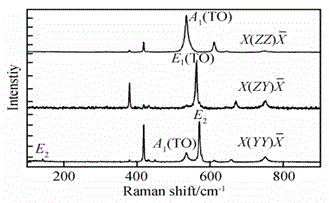

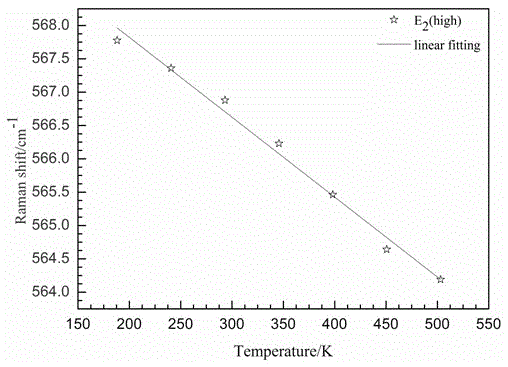

[0043] Step 2, conduct variable temperature Raman test on the GaN sample;

[0044] 1) Place the cleaned GaN epitaxial film sample on the Raman scattering test bench, adjust the Raman scattering instrument, connect the variable temperature platform and the liquid nitrogen tank, and set the test temperature range and step len...

Embodiment 2

[0061] A Raman scattering method for GaN thermal expansion coefficient measurement comprises the following steps:

[0062] Step 1, sampling and cleaning the GaN epitaxial film sample;

[0063] Use a diamond glass knife to slice the grown GaN film sample with a diameter of 2 inches to make a sample with a size of about 1cm×1cm. The GaN epitaxial layer film is cleaned on the surface, and the a-plane GaN epitaxial layer The film is placed in a vacuum of 5.0×10 -3 In the mbar CVD furnace chamber, nitrogen gas with a flow rate of 60-100 liters per minute is introduced at room temperature to remove scratches and surface attachments on the surface of the film;

[0064] Step 2, conduct variable temperature Raman test on the GaN sample;

[0065] 1) Place the cleaned GaN epitaxial film sample on the Raman scattering test bench, adjust the Raman scattering instrument, connect the variable temperature platform and the liquid nitrogen tank, and set the test temperature range and step len...

Embodiment 3

[0082] A Raman scattering method for GaN thermal expansion coefficient measurement comprises the following steps:

[0083] Step 1, sampling and cleaning the GaN epitaxial film sample;

[0084] Use a diamond glass knife to slice the grown GaN film sample with a diameter of 2 inches to make a sample with a size of about 1cm×1cm. The GaN epitaxial layer film is cleaned on the surface, and the a-plane GaN epitaxial layer The film is placed in a vacuum of 5.0×10 -3 In the mbar CVD furnace chamber, nitrogen gas with a flow rate of 60-100 liters per minute is introduced at room temperature to remove scratches and surface attachments on the surface of the film;

[0085] Step 2, performing temperature-varying Raman tests on the GaN epitaxial layer thin film sample;

[0086] 1) Place the cleaned GaN epitaxial film sample on the Raman scattering test bench, adjust the Raman scattering instrument, connect the variable temperature platform and the liquid nitrogen tank, and set the test t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com