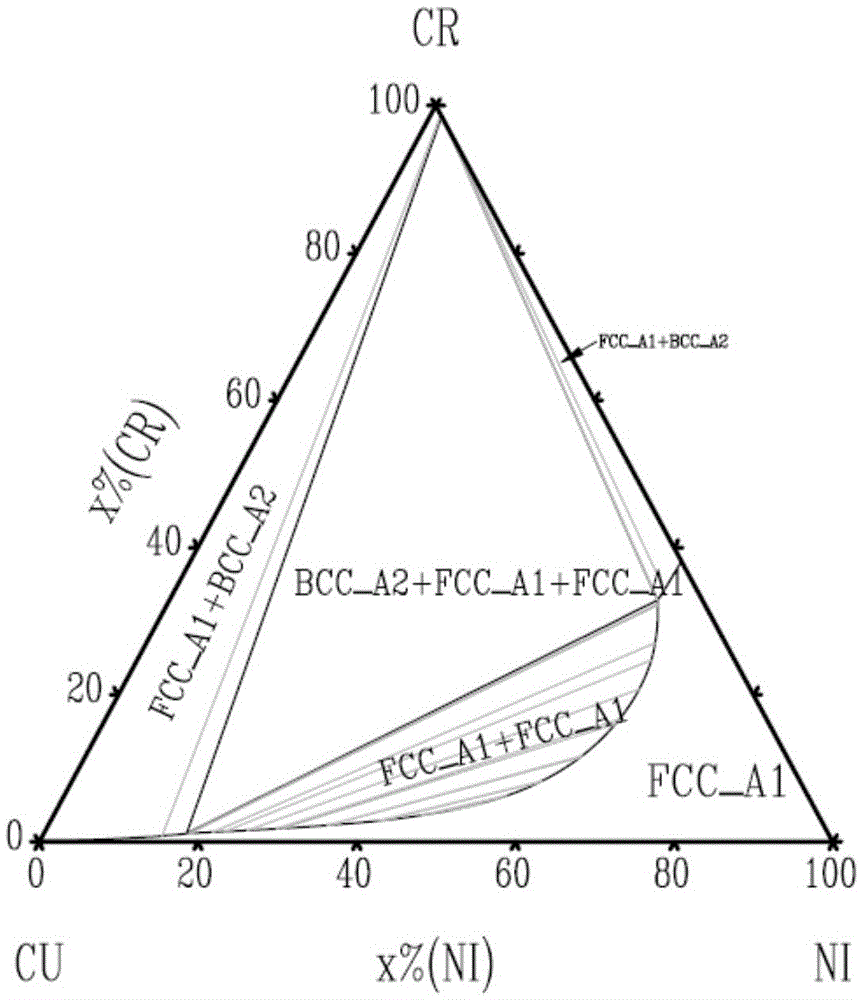

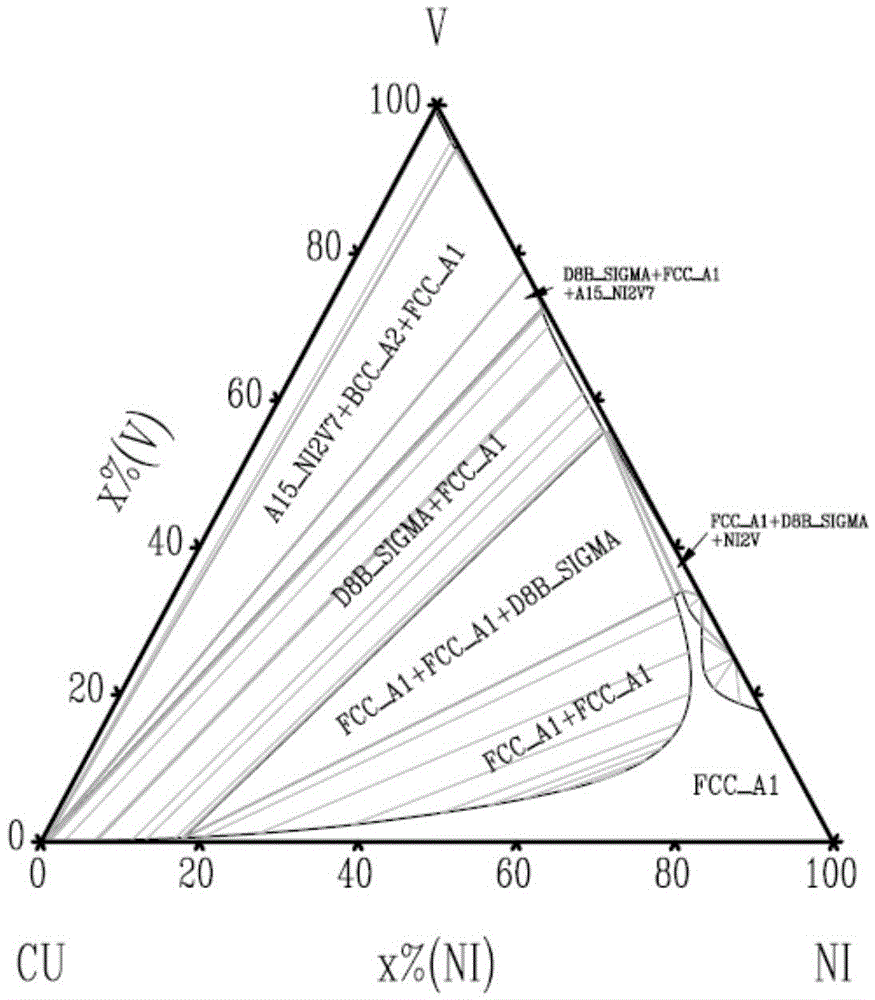

Application of copper-nickel alloy based on spinodal decomposition as reinforced constant-resistivity alloy

A copper-nickel alloy and amplitude modulation decomposition technology, which is applied in the field of resistance alloy materials, can solve problems such as the inability to strengthen the second phase particles, and achieve the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

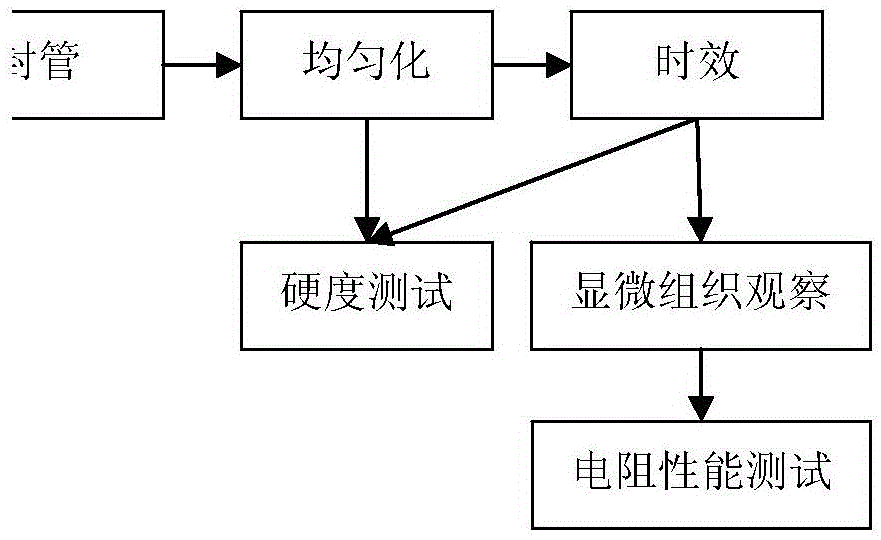

[0051] According to (Cu,Ni) 82% Cr 18% (at.%) The raw materials of Cu, Ni and Cr after shearing and cleaning are weighed, put into an electric arc melting furnace for smelting, and an alloy ingot with uniform composition is obtained. Seal the above alloy ingot into a vacuum degree of 5×10 -3 In the quartz tube of Pa, it is then kept at 1100°C for 10h for solid solution treatment and then water quenched to keep the material in fcc single phase, and aged at 800°C for 6h to cause amplitude modulation decomposition, that is, (Cu,Ni) based on amplitude modulation decomposition strengthening ) 82% Cr 18% Alloy, its resistivity changes with temperature and the morphology characteristics under the scanning electron microscope are as follows: Figure 4 and Figure 15 shown.

Embodiment 2

[0053] According to (Cu,Ni) 94% Cr 6% (at.%) The raw materials of Cu, Ni and Cr after shearing and cleaning are weighed, put into an electric arc melting furnace for smelting, and an alloy ingot with uniform composition is obtained. Seal the above alloy ingot into a vacuum degree of 5×10 -3 In the quartz tube of Pa, it is then kept at 1100°C for 10h for solid solution treatment and then water quenched to keep the material in fcc single phase, and aged at 800°C for 6h to cause amplitude modulation decomposition, that is, (Cu,Ni) based on amplitude modulation decomposition strengthening ) 94% Cr 6% Alloy, its resistivity changes with temperature and the morphology characteristics under the scanning electron microscope are as follows: Figure 5 and Figure 16 shown.

Embodiment 3

[0055] According to (Cu,Ni) 95% Cr 5% (at.%) The raw materials of Cu, Ni and Cr after shearing and cleaning are weighed, put into an electric arc melting furnace for smelting, and an alloy ingot with uniform composition is obtained. Seal the above alloy ingot into a vacuum degree of 5×10 -3 In a quartz tube of Pa, heat preservation at 1100°C for 10h for solid solution treatment and then water quenching to keep the material in fcc single phase, aging at 600°C or 800°C for 1h, 6h, 24h, 72h to cause amplitude modulation decomposition, namely (Cu,Ni) based on amplitude modulation decomposition strengthening 95% Cr 5% Alloy, the resistivity of the alloy aged at 800℃ for 6h changes with temperature and the morphology characteristics under the scanning electron microscope are as follows Image 6 and Figure 17 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com