A cao‑sio2‑b2o3 calcium-rich double-radical system phosphor

A technology of cao-sio2-b2o3 and phosphor powder, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of increasing the manufacturing process, difficulty in trichromatic emission, and increasing production costs, and achieves good stability and excellent preparation process Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 10.98CaO-4SiO 2 -B 2 o 3 -0.02Ce 2 o 3 (Denoted as 1# sample) Synthesis of phosphor powder

[0017] Weigh 1.4572g CaCO according to the stoichiometric ratio 3 , 0.3246g SiO 2 , 0.1670g H 3 BO 3 and 0.0511 g CeO 2 Put it in an agate mortar, add an appropriate amount of acetone to assist in grinding the raw materials evenly, put the mixture in a corundum crucible, and calcinate it in a high-temperature resistance furnace at 1250°C for 12 hours under a C reducing atmosphere, take it out and grind it to get the final product.

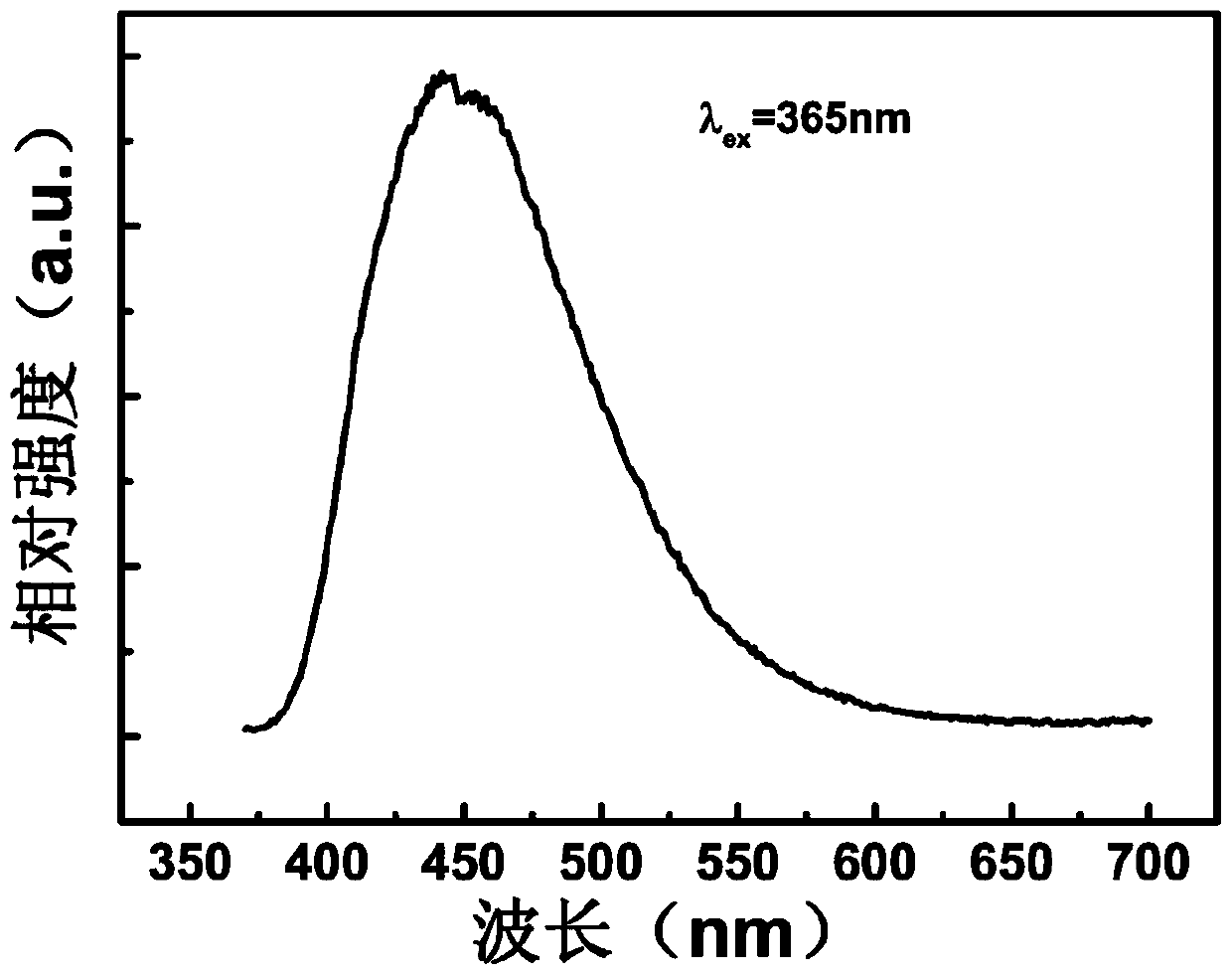

[0018] The photoluminescence spectrum of the 1# fluorescent powder that this embodiment case prepares is as follows figure 1 As shown, under the excitation of 365nm ultraviolet light, 1# phosphor exhibits strong blue light emission, the luminescent center is located at 440nm, and its chromaticity coordinates (1931) are: (x=0.2128, y=0.428). .

Embodiment 2

[0020] 10.995CaO-4SiO 2 -B 2 o 3 Synthesis of -0.005EuO (marked as 2# sample) phosphor

[0021] Weigh 1.4913g CaCO according to the stoichiometric ratio 3 , 0.3272g SiO 2 , 0.1684g H 3 BO 3 and 0.0132gEu 2 o 3 Put it in an agate mortar, add an appropriate amount of acetone to assist in grinding the raw materials evenly, put the mixture in a corundum crucible, and calcinate it in a high-temperature resistance furnace at 1250°C for 12 hours under a C reducing atmosphere, take it out and grind it to get the final product.

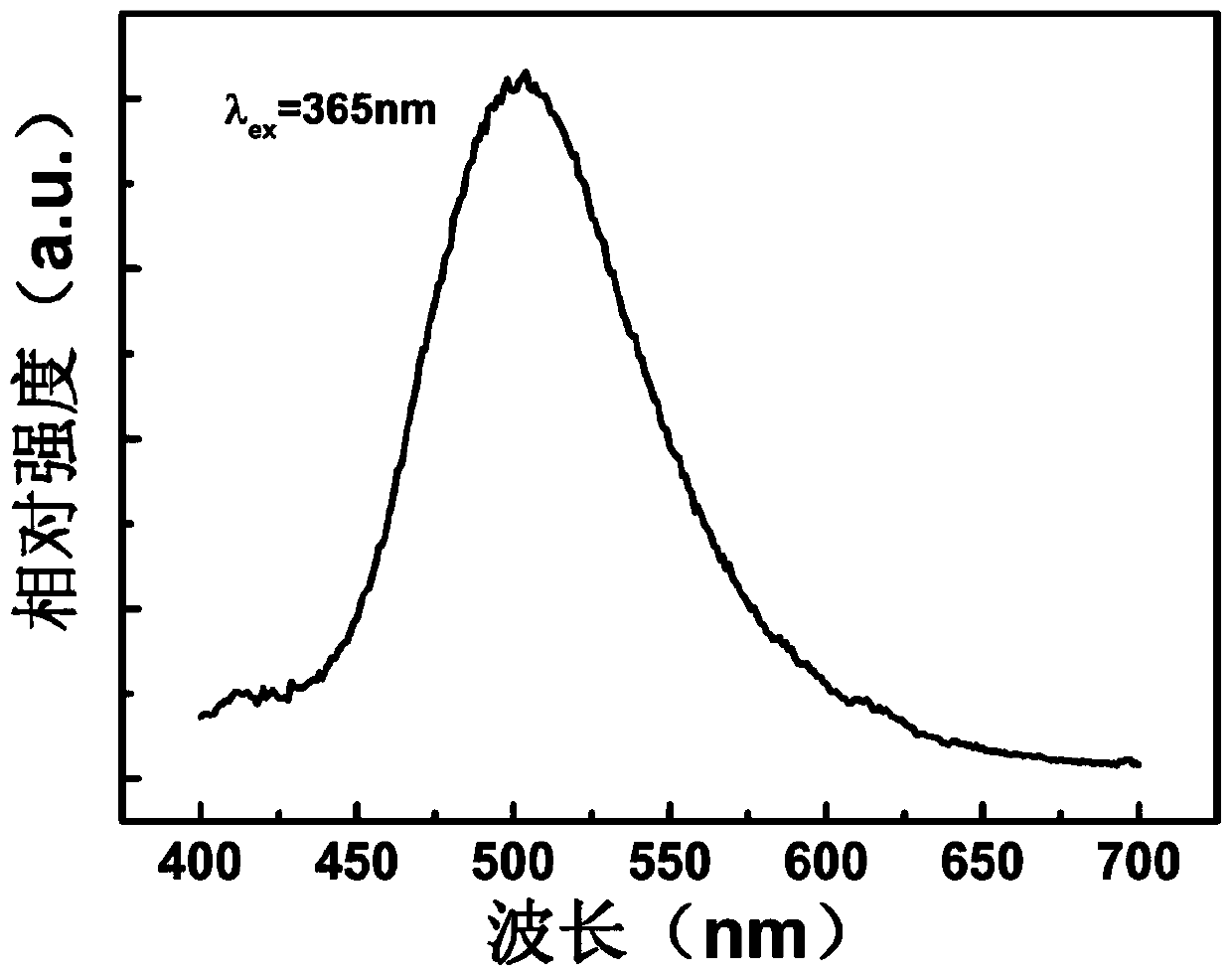

[0022] The luminescence spectrum of the 2# fluorescent powder prepared by this implementation case is as follows figure 2 As shown, under the excitation of 365nm ultraviolet light, the 2# phosphor exhibits strong green light emission, the luminescent center is located at 505nm, and its chromaticity coordinates (1931) are: (x = 0.1541, y = 0.1082).

Embodiment 3

[0024] 10.9CaO-4SiO 2 -B 2 o 3 -0.1Eu 2 o 3 (Denoted as 3# sample) Synthesis of Phosphor Powder

[0025] Weigh 1.2798g CaCO according to the stoichiometric ratio 3 , 0.3104g SiO 2 , 0.1597g H 3 BO 3 and 0.2500gEu 2 o 3 Put it in an agate mortar, add an appropriate amount of acetone to assist in grinding the raw materials evenly, put the mixture in a corundum crucible, and calcinate it in a high-temperature resistance furnace at 1250°C for 12 hours under a C reducing atmosphere, take it out and grind it to get the final product.

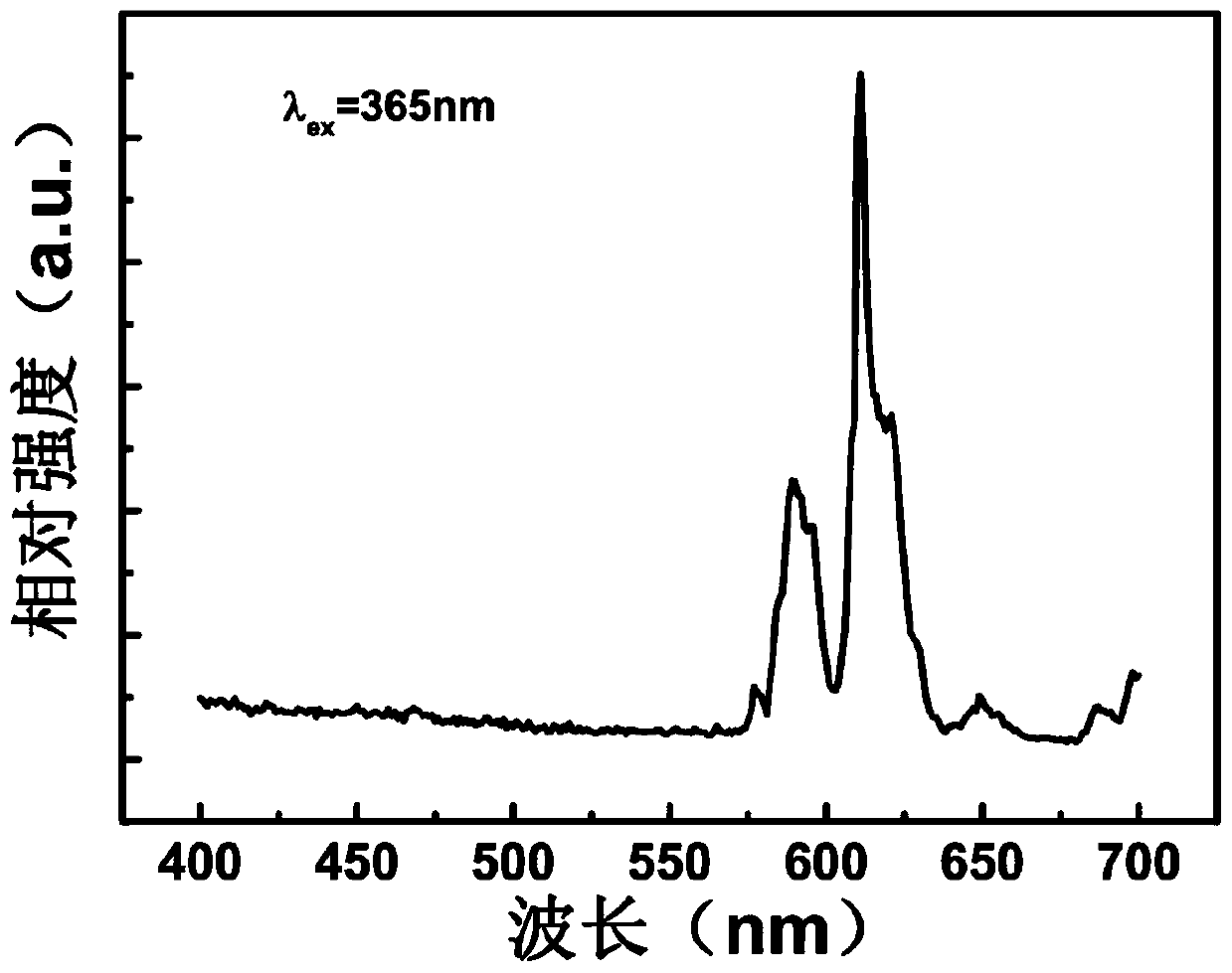

[0026] The luminescence spectrum of the 3# fluorescent powder prepared by this implementation case is as follows image 3 As shown, under the excitation of 365nm ultraviolet light, the 3# phosphor exhibits strong red light emission, the luminescent center is located at 611nm, and its chromaticity coordinates (1931) are: (x = 0.4984, y = 0.3257).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com