Cow achilles tendon collagen purification method and sponge preparation thereof

A technology of tendon collagen and collagen, applied in the field of collagen sponge preparation, can solve the problems of collagen sponge cracks, high market price, complicated process, etc., and achieve the effects of low production cost, wide promotion value, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

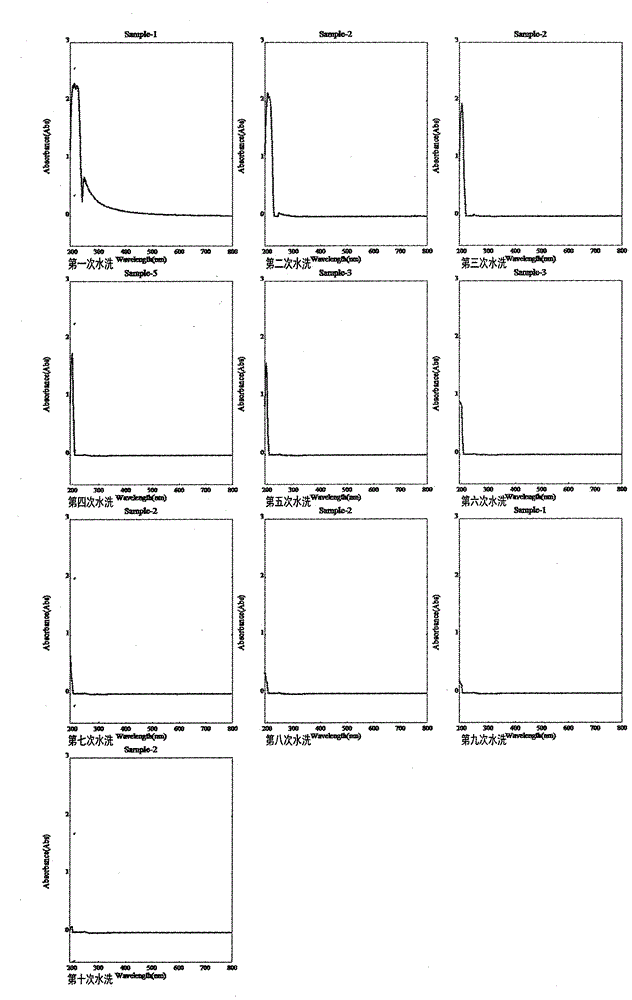

[0013] Embodiment 1 Purification of collagen and the specific steps of sponge preparation thereof are as follows:

[0014] 1) Use a blade to remove impurities such as fascia, muscle and fat from the bovine Achilles tendon that has been frozen at -20°C, cut into 0.3mm thick with a slicer, and then fully pulverize with a grinder;

[0015] 2) Remove impurity protein with dilute alkali solution for 6-8 hours, wash with distilled water until neutral, then degrease with alcohol, wash with distilled water until neutral and no peculiar smell;

[0016] 3) Dissolved in a dilute acid solution with a pH of 2 to 3;

[0017] 4) adding an appropriate amount of pepsin to the above solution, the weight ratio of collagen to pepsin is 25:1, stirring at 4°C for 48 hours;

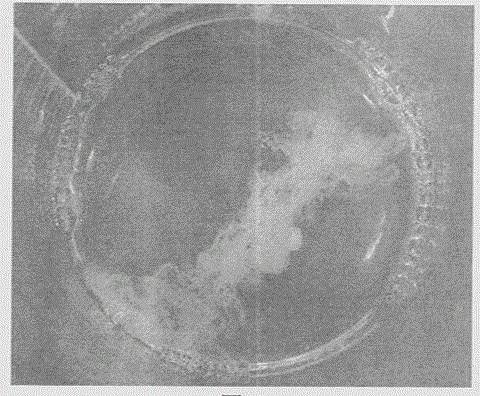

[0018] 5) Centrifuge the extract, collect the supernatant, adjust the collagen solution to neutral with 10mol / L sodium hydroxide, collect the obtained collagen precipitate, first add 0.5mol / L acetic acid to dissolve the collag...

Embodiment 2

[0021] Embodiment 2 The specific steps for the preparation of purified collagen and its sponge are as follows:

[0022] 1) Use a blade to remove impurities such as fascia, muscle and fat from the bovine Achilles tendon that has been frozen at -20°C, cut into 0.3mm thick with a slicer, and then fully pulverize with a grinder;

[0023] 2) Remove impurity protein with dilute alkali solution for 6-8 hours, wash with distilled water until neutral, then degrease with alcohol, wash with distilled water until neutral and no peculiar smell;

[0024] 3) Dissolved in a dilute acid solution with a pH of 2 to 3;

[0025] 4) adding an appropriate amount of pepsin to the above solution, the weight ratio of collagen to pepsin is 50:1, stirring at 4°C for 60 hours;

[0026] 5) Centrifuge the extract, collect the supernatant, adjust the collagen solution to neutral with 10mol / L sodium hydroxide, collect the obtained collagen precipitate, first add 0.5mol / L acetic acid to dissolve the collagen ...

Embodiment 3

[0029] Embodiment 3 The specific steps for the preparation of purified collagen and its sponge are as follows:

[0030] 1) Use a blade to remove impurities such as fascia, muscle and fat from the bovine Achilles tendon that has been frozen at -20°C, cut into 0.3mm thick with a slicer, and then fully pulverize with a grinder;

[0031] 2) Remove impurity protein with dilute alkali solution for 6-8 hours, wash with distilled water until neutral, then degrease with alcohol, wash with distilled water until neutral and no peculiar smell;

[0032] 3) Dissolved in a dilute acid solution with a pH of 2 to 3;

[0033] 4) adding an appropriate amount of pepsin to the above solution, the weight ratio of collagen to pepsin is 100:1, stirring at 4°C for 72 hours;

[0034] 5) Centrifuge the extract, collect the supernatant, adjust the collagen solution to neutral with 10mol / L sodium hydroxide, collect the obtained collagen precipitate, first add 0.5mol / L acetic acid to dissolve the collagen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com