Insulation pipe forming machine

A molding machine and thermal insulation pipe technology, which is applied to ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of long preparation process and complicated production process of thermal insulation pipes, and achieve uniform heat and the effect of curing molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

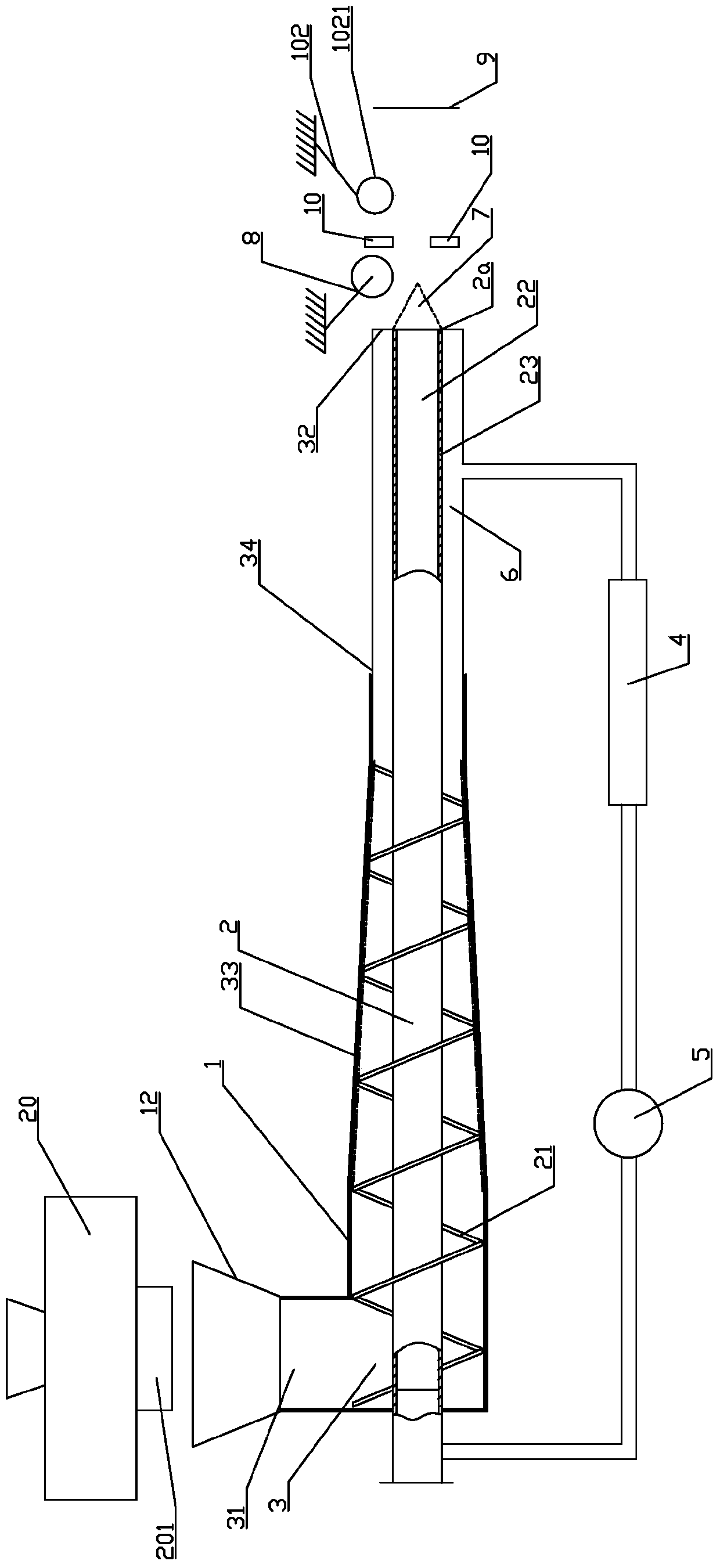

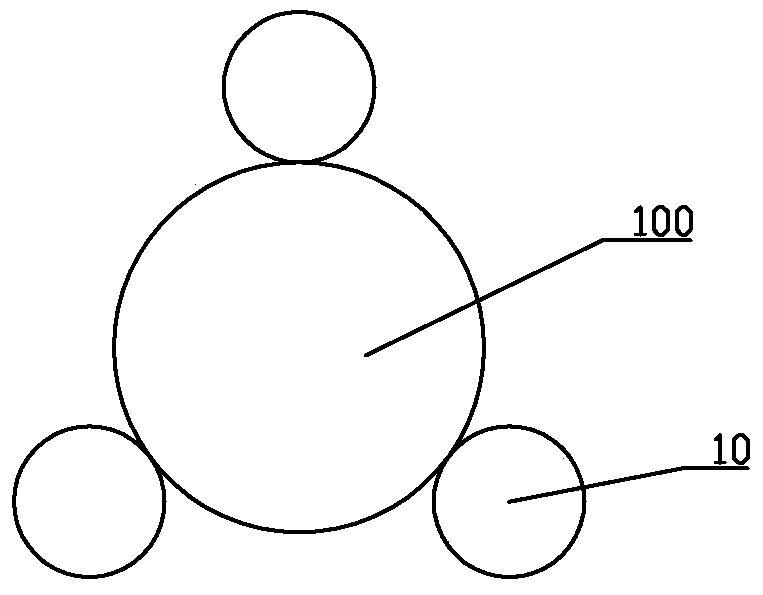

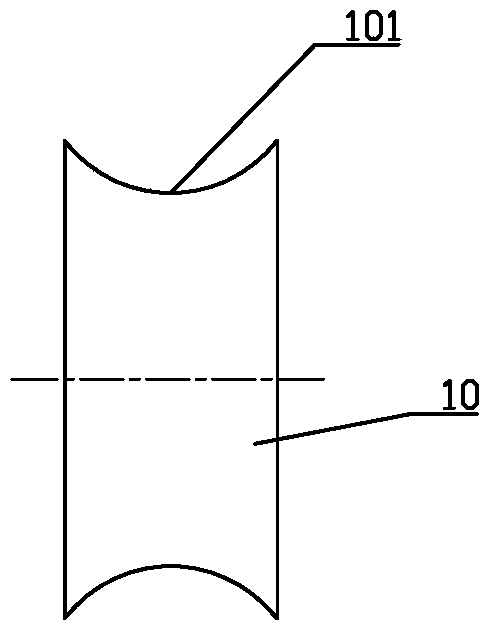

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — image 3 ;

[0022] This embodiment provides an insulation pipe forming machine, including a shell 1 and a screw 2 . As shown in the figure, wherein, the housing has a cavity 3, the cavity 3 has a feed port 31 and a discharge port 32, and the cavity is located between the feed port and the discharge port and has a circular frustum section 33 and a cylinder. paragraph 34. The truncated cone section 33 is adjacent to the cylindrical section 34 , and the cylindrical section 34 is farther away from the feed inlet 31 than the truncated circular section. Such as figure 1 As shown in , the inner diameter of the circular table section gradually decreases from the inlet to the outlet. The inner diameter in the cylindrical section does not change, and becomes a straight cylinder. The housing 1 is rotatably provided with a screw 2 having a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com