Tower-shaped repairing device of hotly-rolled steel coil

A hot-rolled steel coil and tower-shaped technology is applied in the field of hot-rolled steel coil tower-shaped repairing devices, which can solve the problems of wear of parts, bending of stress points, large driving devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

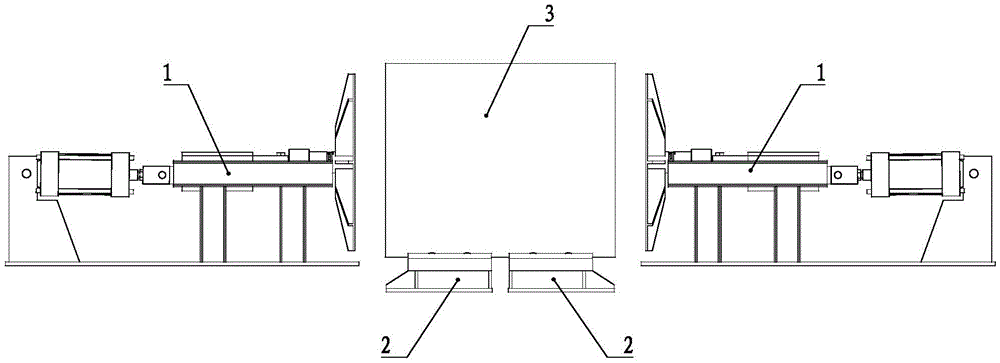

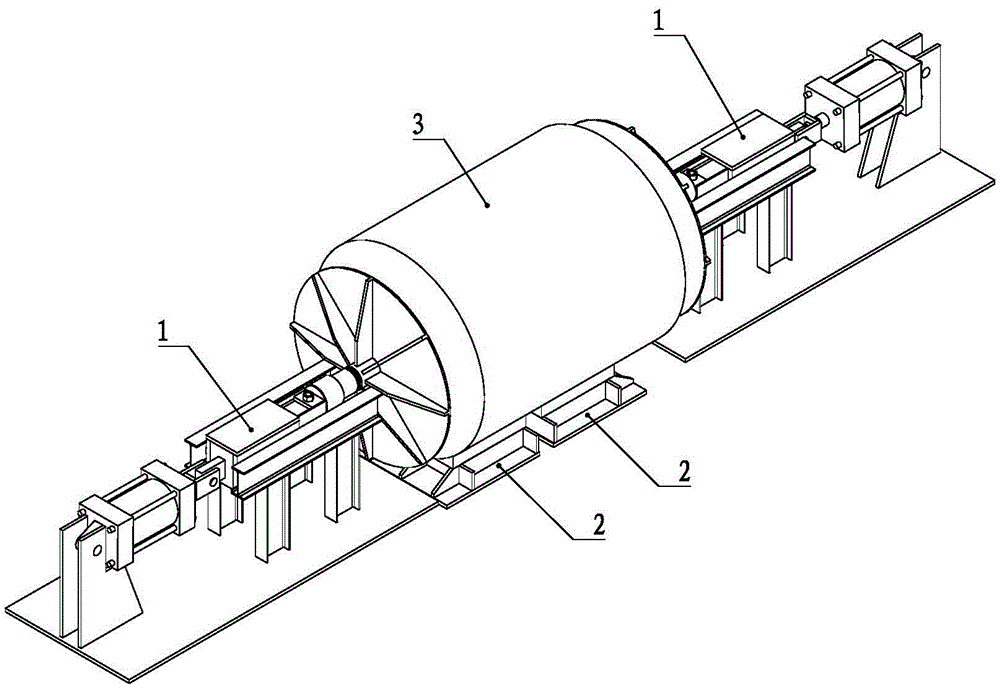

[0039] Such as Figure 1 to Figure 3 As shown, a hot-rolled steel coil tower repair device includes a side thrust mechanism 1, a saddle 2, a power system and a control system. The saddle 2 is used to place the steel coil 3, and the number of the saddle 2 is two, and the saddle 2 can move along the axial direction of the steel coil 3, so that it is mainly for adapting to steel coils of different widths 3. To increase the scope of application of a hot-rolled steel coil tower repair device. The side pushing mechanism 1 is respectively arranged on both sides of the saddle 2, and exerts force on the steel coil 3 with tower-shaped defects from both sides during operation, so as to eliminate the tower-shaped defects of the steel coil. The side thrust mechanism 1 is respectively connected with the power system and the control system.

[0040] Such as Figure 4 to Figure 6 As shown, the saddle 2 includes a base 21 and a mounting plate 22, the base 21 is provided with a V-shaped pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com