High-precision high temperature and corrosion resisting nanometer filter cloth with adsorption and decomposition functions and making method thereof

A high-precision, high-temperature-resistant technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of PTFE membrane breakage and failure, increase the cost of dust removal for enterprises, and increase the cost of dust removal, so as to save capital investment and protect Acid and alkali corrosion resistance, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

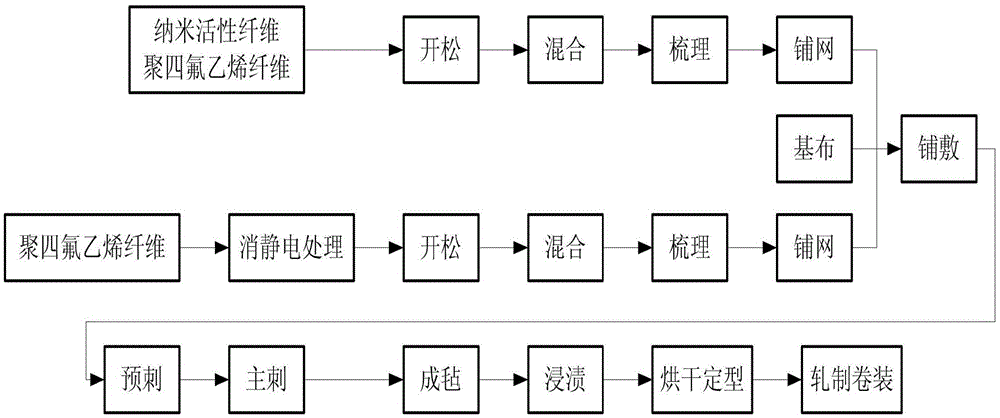

Method used

Image

Examples

Embodiment

[0026] A nanometer high-precision high-temperature-resistant and corrosion-resistant filter cloth with adsorption and decomposition functions in this embodiment includes a base cloth layer 1 in the middle. The lower surface of layer 1 is provided with a breathable and clean air surface layer 3, and the superfine fiber dust-receiving surface layer 2 is composed of nano-activated carbon fibers and polytetrafluoroethylene superfine fiber netting. 2 and the air-permeable clean air surface layer 3 are needle-punched into felt, and the felt surface has a PTFE emulsion impregnated layer 4 .

[0027] Among them, the two components of the superfine fiber dust-facing surface layer are composed of 20% nano-activated carbon fibers and 80% polytetrafluoroethylene superfine fibers, and the fineness of the polytetrafluoroethylene superfine fibers is preferably 1D. The air-permeable and air-cleaning surface layer 3 is made of polytetrafluoroethylene short fiber netting, and the base cloth lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com