Method for automatically adjusting rotating speed of roller according to production states

A drum speed, automatic adjustment technology, applied in the processing of tobacco, tobacco, application, etc., can solve the problems of affecting the quality control of the subsequent process, the increase of the operating frequency setting value, and the sudden increase of the drum outlet material, so as to shorten the transfer time , reduce misjudgment rate, and balance the effect of material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

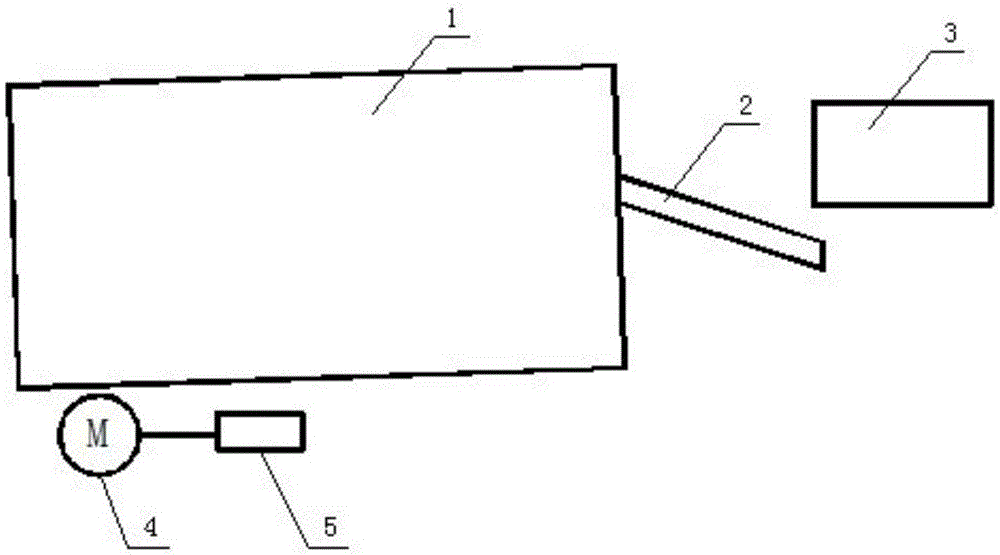

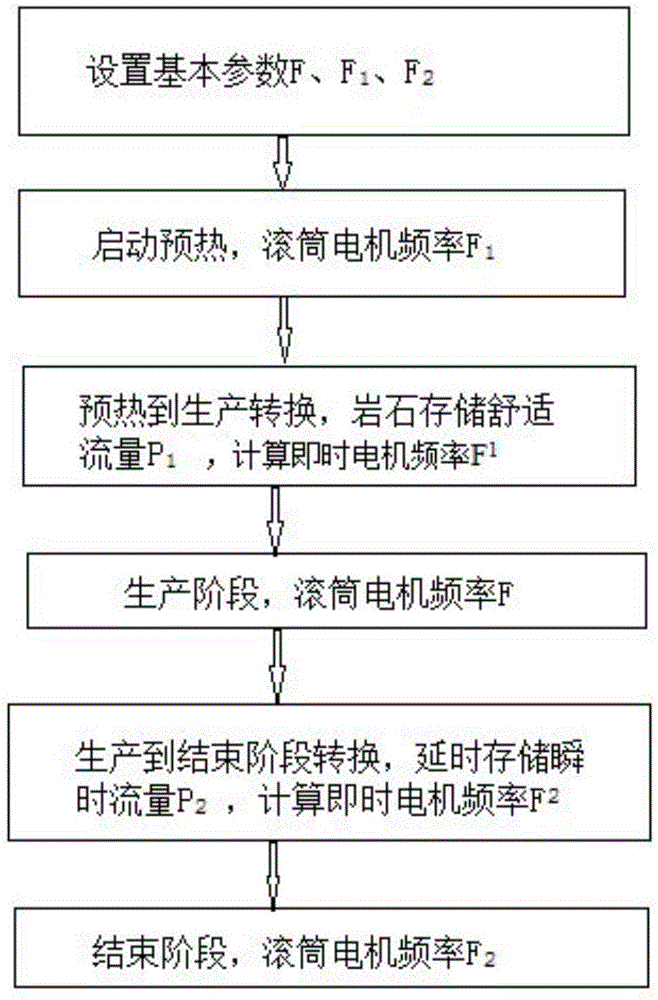

[0026] like figure 1 and figure 2 As shown, this method automatically adjusts the rotating speed of the drum according to the production status. The device carrying the method includes a drum 1, a feeding vibrating tank 2, an electronic scale 3 and a drum motor 4. The electronic scale 3 is located at the front end of the feeding vibrating tank 2. The other end of the vibration tank 2 is connected with the drum 1, and the drum motor 4 is used as the power unit of the drum 1, and its circuit is also provided with a frequency converter 5, and the electronic scale 3 and the frequency converter 5 are all connected with the PLC controller.

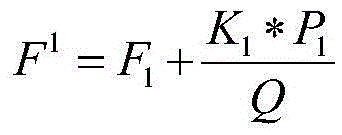

[0027] According to the operating capacity and process requirements of the field equipment, the material process flow Q in this embodiment is 6000Kg / h, the drum speed is 11r / min, the corresponding motor frequency is 40HZ, and the drum motor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap