Vegetable rice crust, and preparation method thereof

A production method and technology of crispy rice, which is applied to the functions of food ingredients, fat-containing food ingredients, food forming, etc., can solve the problems of low nutritional content, excessive addition of additives, and hard crispy rice, so as to achieve uniform mixing and good , low production cost, fresh flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The vegetable rice crackers of this embodiment are mainly made of the following parts by weight: 40 parts of rice, 10 parts of buckwheat, 8 parts of millet, 8 parts of soybeans, 8 parts of peas, 6 parts of water chestnuts, 6 parts of rape, and 10 parts of rapeseed oil. Parts, 5 parts of citrus peel, 0.5 parts of table salt, and the rapeseed oil is cold-pressed oil obtained by cold pressing.

[0035] The production method is as follows:

[0036] S1: Weigh each raw material in the above parts by weight, grind rice, buckwheat, millet, and soybean into powder form, and chop peas, rape, water chestnut, and citrus peel;

[0037] S2: Put the processed above raw materials into a mixer for mixing, add rapeseed oil and salt in the middle to make the mixing evenly and form a dough;

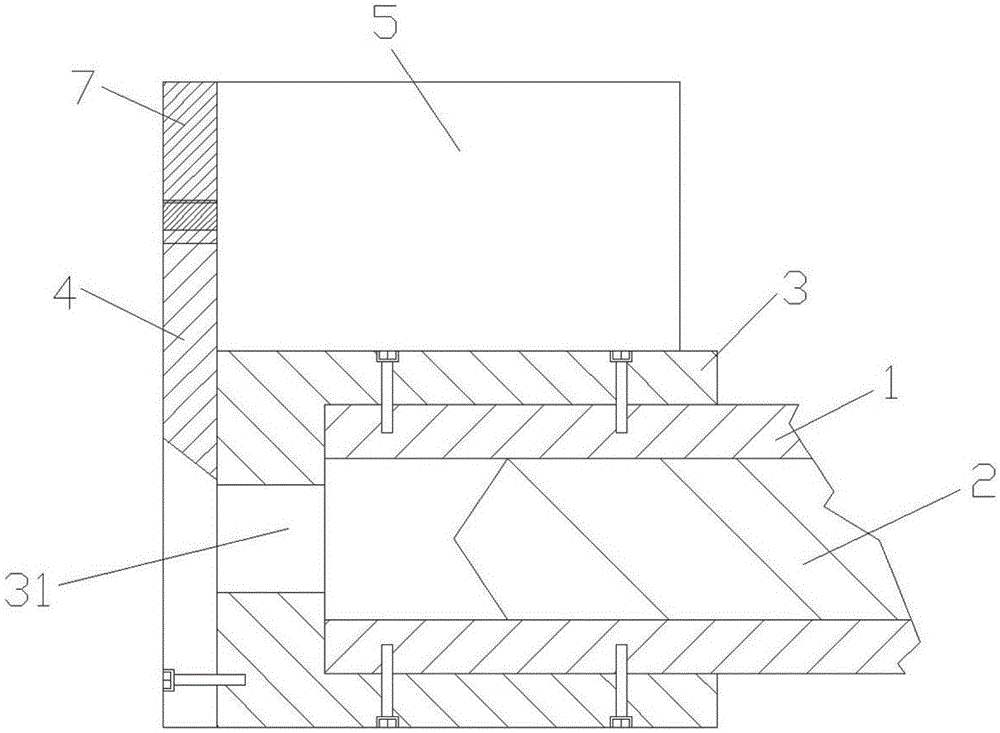

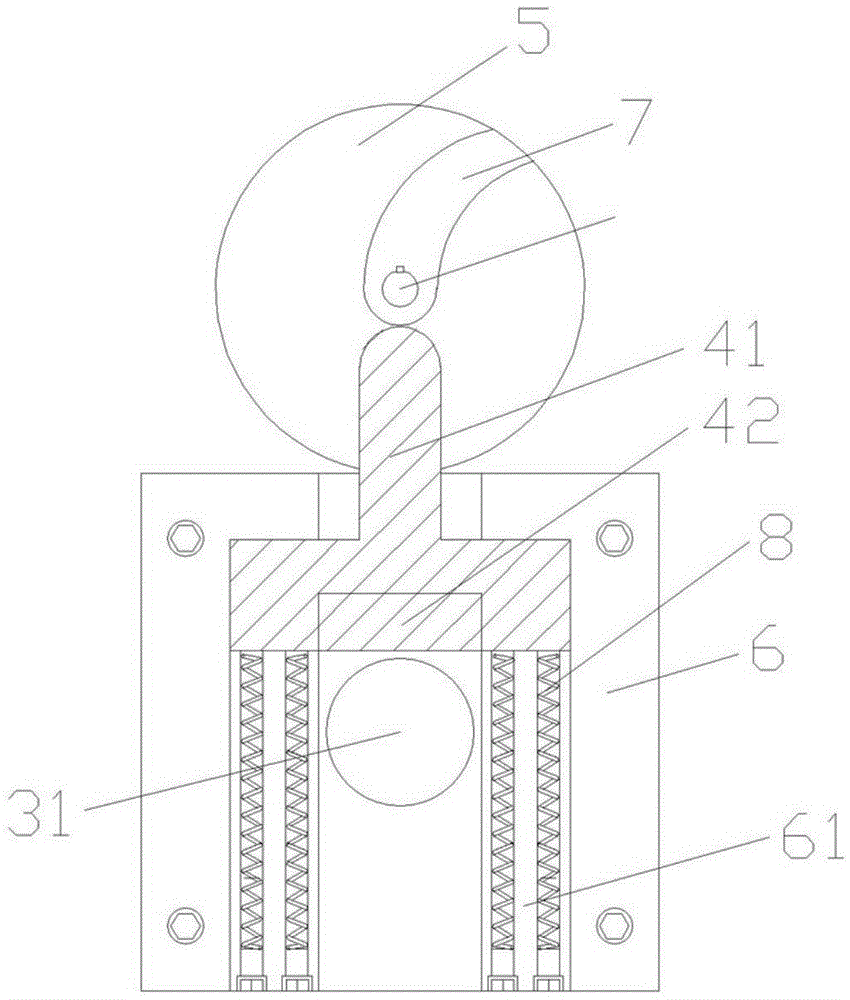

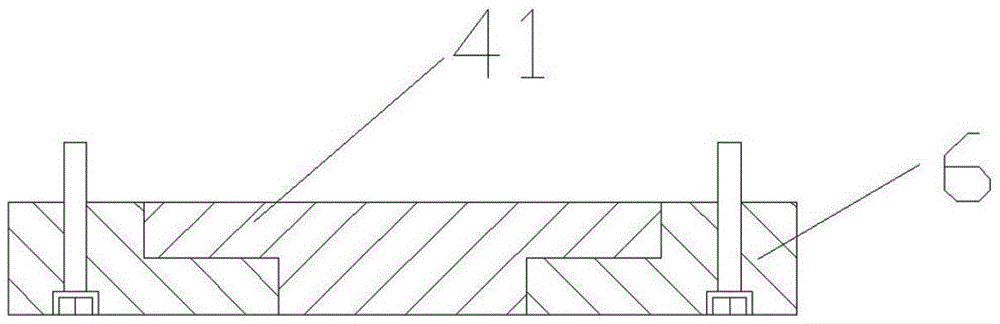

[0038] S3: Put the dough into the rice cracker mold for extrusion, and cut into dough pieces with a thickness of 6mm;

[0039] S4: The cut noodles fall onto the baking belt set under the extrusion end of the r...

Embodiment 2

[0042] The vegetable croissants of this embodiment are mainly made of the following parts by weight: 30 parts of rice, 8 parts of buckwheat, 6 parts of millet, 6 parts of soybeans, 8 parts of peas, 8 parts of water chestnuts, 8 parts of rapeseed oil, 9 parts of rapeseed oil. 4 parts, 4 parts of citrus peel, 0.5 parts of table salt, and the rapeseed oil is cold-pressed oil obtained by cold pressing.

[0043] The production method is the same as in Example 1.

Embodiment 3

[0045] The vegetable rice crackers of this embodiment are mainly made of the following parts by weight: 30 parts of rice, 8 parts of buckwheat, 8 parts of millet, 8 parts of soybeans, 8 parts of peas, 8 parts of water chestnuts, 5 parts of rape, 10 parts of rapeseed oil Parts, 5 parts of citrus peel, 0.5 parts of table salt, 0.03 parts of sorbic acid, and the rapeseed oil is cold-pressed oil extracted by a cold-pressing method.

[0046] The production method is as follows:

[0047] S1: Weigh each raw material in the above parts by weight, grind rice, buckwheat, millet, and soybean into powder form, and chop peas, rape, water chestnut, and citrus peel;

[0048] S2: Put the processed above raw materials into a mixer for mixing, put rapeseed oil, salt, and sorbic acid in the middle to make the mixing evenly and form a dough;

[0049] S3: Put the dough into the rice cracker mold for extrusion, and cut into dough pieces with a thickness of 6mm;

[0050] S4: The cut noodles fall onto the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com