Three-tube type full wave rectifier

A full-wave rectification and tube-type technology, applied in the direction of irreversible AC power input conversion to DC power output, etc., can solve the problems of large rectifier energy consumption, large heat sink volume, large rectification energy consumption, etc.

Inactive Publication Date: 2016-05-18

袁宏文

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the rectification power supply circuit, we know that under the condition of single-phase transformer-free conversion from AC to DC, a bridge rectifier circuit is required to obtain a full-wave waveform current, and four diodes are used for bridge rectification. The half-wave current has to flow through two rectifier diodes, the rectification consumes a lot of energy, and the heat sink is used to dissipate heat from the diodes. The heat sink is large in size, so the rectifier not only consumes a lot of energy, but also has a large volume.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

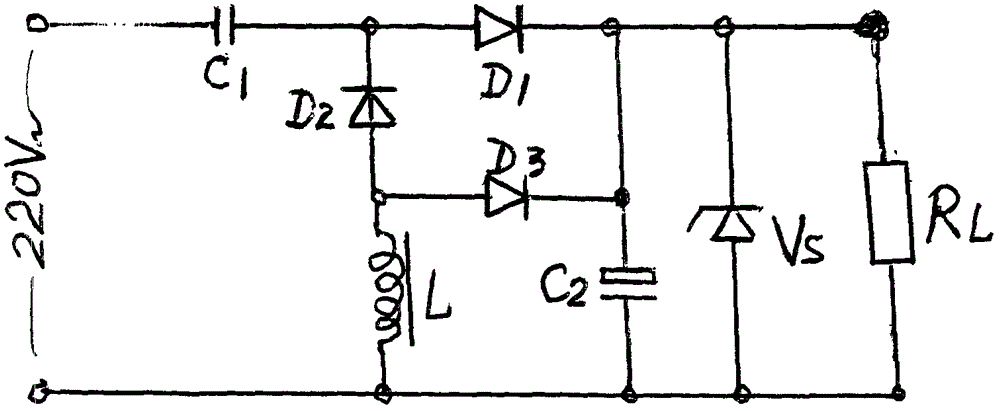

[0008] As shown in the figure, a three-tube full-wave rectifier is composed of capacitor C1. (1μF400V), diodes D1, D2, D3{1N4007}, inductor L (5mH), voltage divider-filter capacitor C2{470μF / 16V }, Zener tube VS{5V} and the load are combined.

[0009] The design is practical and effective.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a three-tube type full wave rectifier, which is composed of a voltage dropping capacitor C1, positive and negative half wave rectifier diodes D1 and D2, a negative half wave energy storage inductor L, an energy storage output diode D3, a voltage dividing filter capacitor C2, a voltage regulating tube VS and a load RL. Three diodes and one inductor replace a four-tube rectifier bridge for realizing full wave rectification, and the energy consumption and the size of the rectifier are reduced.

Description

Technical field: [0001] The design of the three-tube full-wave rectifier is an AC rectification power supply. technical background: [0002] In the rectification power supply circuit, we know that under the condition of single-phase transformer-free conversion from AC to DC, a bridge rectifier circuit is required to obtain a full-wave waveform current, and four diodes are used for bridge rectification. The half-wave current has to flow through two rectifier diodes, the rectification consumes a lot of energy, and the diode needs to use a heat sink to dissipate heat. The heat sink is large in size, so the rectifier not only consumes a lot of energy, but also cannot be small. Can we reduce the energy consumption and volume while achieving full-wave rectification output under the condition of reducing the number of diodes? This is our goal. Invention content: [0003] The purpose of this design is to provide a full-wave rectifier circuit electrical appliance that not only red...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02M7/06

Inventor 袁宏文袁菱

Owner 袁宏文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com