Preparation method of micro-nano dimensional graphene/lithium titanate composite negative electrode material

A negative electrode material, micro-nano-scale technology, applied in the field of preparation of graphene/lithium titanate composite negative electrode material, can solve the problems affecting the electrical conductivity of the material, long diffusion distance, low specific capacity, etc., to improve the reaction efficiency and diffusion distance Small, great performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

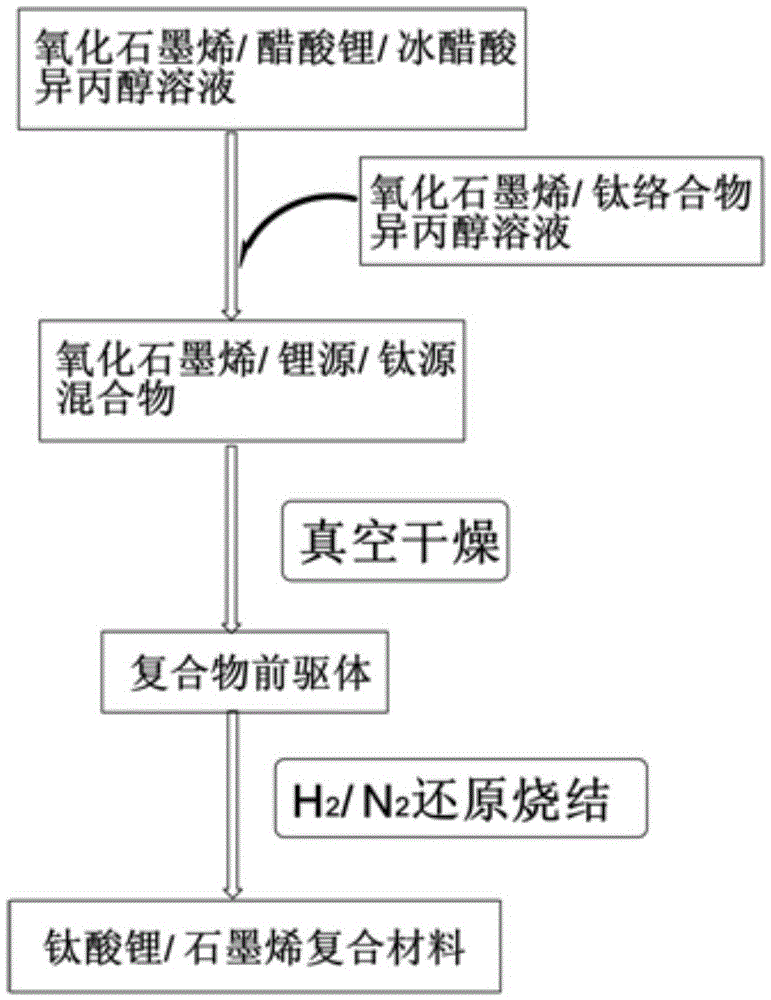

[0058] Such as figure 1 As shown, the preparation method of a micro-nano-scale graphene / lithium titanate composite negative electrode material in this embodiment is as follows:

[0059] 1. Selection of raw materials and proportioning

[0060] Deionized water, made by deionized water preparation machine, 30kg;

[0061] Diisopropoxy ethyl diacetoacetate titanium complex (purity) ≥ 98%, 6kg;

[0062] Monolayer graphene oxide, 15kg;

[0063] Isopropanol solution (purity) ≥ 99.9%, 3000L;

[0064] Glacial acetic acid (purity) ≥ 99.9%, 2kg;

[0065] Anhydrous lithium acetate (purity) ≥ 99%, 1kg;

[0066] Deionized water: titanium complex: graphene oxide: glacial acetic acid: lithium acetate mass ratio = 30:6:15:2:1

[0067] Second, select the main equipment:

[0068] Water bath steam heating enamel reaction pot (including condenser, high position and low tank, vacuum system);

[0069] Vacuum drying oven; Pulverizer; Reduction high temperature furnace; Ingredients pot;

[007...

Embodiment 2

[0095] The difference between this embodiment and embodiment 1 is:

[0096] 1. Raw material ratio

[0097] Deionized water, 36kg;

[0098] Diisopropoxy ethyl diacetoacetate titanium complex, 7.3kg;

[0099] Monolayer graphene oxide, 18kg;

[0100] Isopropanol solution, 3600L;

[0101] Glacial acetic acid, 2.4kg;

[0102] Anhydrous lithium acetate, 1.3kg;

[0103] Mass ratio of deionized water: titanium complex: graphene oxide: glacial acetic acid: lithium acetate = 36:7.3:18:2.4:1.3

[0104] 2. Preparation steps

[0105] Step (1) When preparing solution B, slowly add the titanium complex into the batching pot B, and stir for 20 minutes;

[0106] Step (2) When synthesizing the precursor of the graphene oxide / lithium titanate composite, control the temperature at 75°C for vacuum dehydration to obtain a colloidal product, place the colloidal product in a vacuum drying oven, and control the temperature at 85°C for vacuum dehydration. In addition to low boilers, block produ...

Embodiment 3

[0114] The difference between this embodiment and embodiment 1 is:

[0115] 1. Raw material ratio

[0116] Deionized water, 32kg;

[0117] Diisopropoxy ethyl diacetoacetate titanium complex, 6.5kg;

[0118] Monolayer graphene oxide, 16kg;

[0119] Isopropanol solution, 3200L;

[0120] Glacial acetic acid, 2.2kg;

[0121] Anhydrous lithium acetate, 1.1kg;

[0122] Mass ratio of deionized water: titanium complex: graphene oxide: glacial acetic acid: lithium acetate = 32:6.5:16:2.2:1.1

[0123] 2. Preparation steps

[0124] Step (1) When preparing solution B, slowly add the titanium complex into the batching pot B, and stir for 15 minutes;

[0125] Step (2) During the synthesis of the graphene oxide / lithium titanate composite precursor, control the temperature at 72°C for vacuum dehydration to obtain a colloidal product, place the colloidal product in a vacuum drying oven, and control the temperature at 82°C for vacuum dehydration. In addition to low boilers, block produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com