Continuous fiber reinforced pressure pipe and forming process thereof

A continuous fiber and forming process technology, applied in the field of continuous fiber reinforced pressure pipe and its forming process, can solve the problems of affecting the mechanical properties of the pipe, unreasonable rib structure, inability to continuously wind, etc., and achieve high ring stiffness, light weight, Not easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

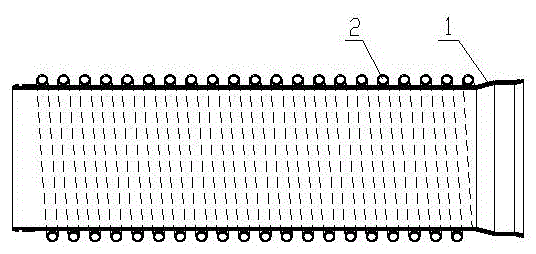

[0030] In this embodiment, a continuous fiber reinforced pressure pipe, such as figure 1 As shown, it consists of a base pipe 1 and a helical tubular reinforcing rib 2 wound and melted on the outer surface of the base pipe 1 .

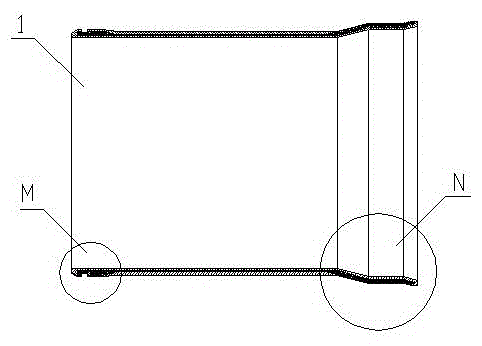

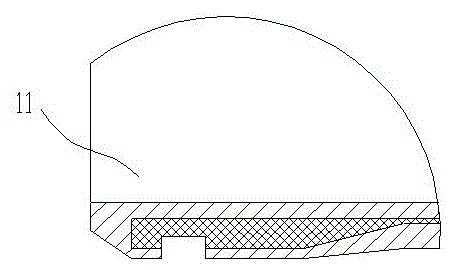

[0031] Specifically, the base pipe 1 is composed of an inner plastic layer, a fiber layer in the middle, and an outer plastic layer on the outside. One end of the base pipe 1 is a socket 11, such as figure 2 , image 3 As shown, the end of the socket 11 is provided with a sealing rubber ring groove, and except for the sealing rubber ring groove, the fiber layer at the socket 11 is wrapped by an inner plastic layer and an outer plastic layer fused into one. The other end of the base pipe 1 is a socket 12, such as figure 2 , Figure 4 As shown, the fiber layer at the socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com