Composite snap-in pile retaining wall construction method and a composite snap-in pile retaining wall structure

A construction method and retaining wall technology, applied to sheet pile walls, underwater structures, foundation structure engineering, etc., can solve problems such as difficulty in meeting the requirements of design and construction units, high support cost, and long construction period, and achieve Improve the overturning capacity of retaining soil and overturn protection, the quality of the pile body is reliable, and the effect of reducing construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The construction method of composite snap pile retaining wall of the present invention comprises the following steps:

[0038] a. Level the site, set out the line to determine the pile position,

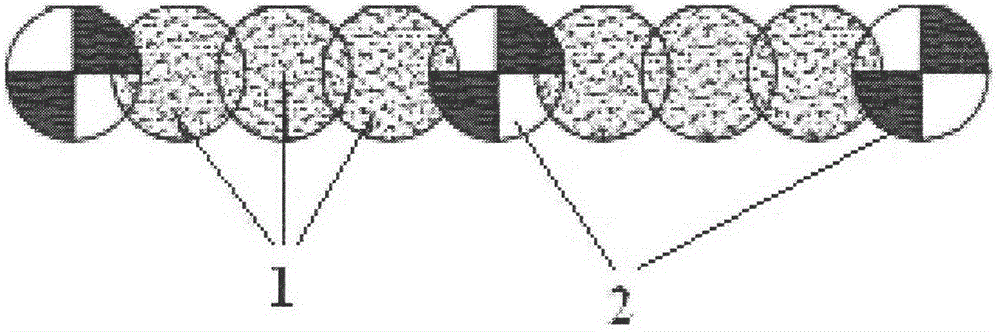

[0039] b. Construct cement-soil mixing piles, and arrange several piles interlocking with each other;

[0040] c. Level the site, check and set out the line, and determine the pile position of the anchor cable bored pile; apply the anchor cable bored pile; use the long spiral drilling process to cut the cement-soil mixing pile on both sides to form holes; press again poured concrete piles;

[0041] d. Fix the prestressed anchor cable in the reinforcement cage of the anchor cable borehole press grouting pile according to the design requirements, and then vibrate the reinforcement cage into the anchor cable borehole press grout pile pile body;

[0042] e. Carry out prestressed anchor cable installation construction;

[0043] f. Pour concrete on the top of the pile to press th...

Embodiment 2

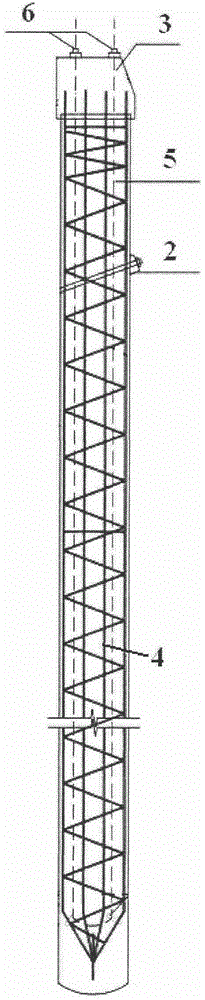

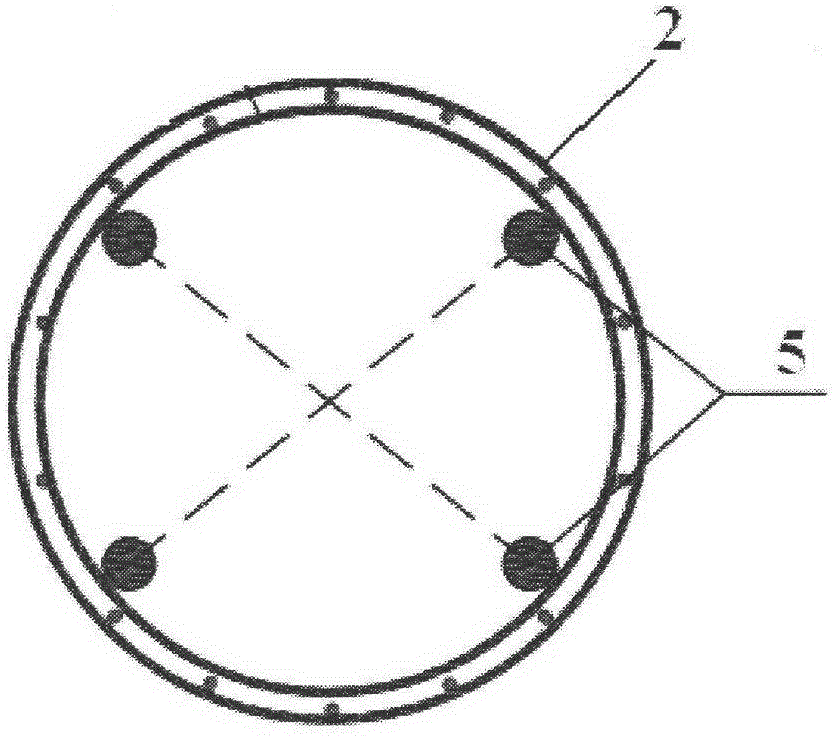

[0049] Such as figure 1 As shown, a kind of compound snap-in pile retaining wall structure of the present invention comprises: several cement-soil mixing pile bodies 1; At least one cement-soil mixing pile body 1 is arranged between the 2 press-grouting pile bodies; the anchor cable drilled press-fill pile body 2 and the cement-soil mixing pile body 1 are interlocked and arranged; as figure 2 and 3 As shown, the anchor cable bored pile body 2 includes a top beam 3, and the top beam 3 is arranged on the top of the anchor cable bored pile body 2; the anchor cable bored pile body 2 is provided with a reinforcement cage 4 and a prestressed anchor cable 5, wherein one end of the prestressed anchor cable 5 is fixed on the end of the reinforcement cage 4 close to the bottom end of the anchor cable drilled pile body 2, The other end of the prestressed anchor cable 5 is anchored to the capping beam 3 through an anchor 6 .

[0050] As a preferred embodiment, the composite snap-in pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com