Technique for directly reducing pellet ore by means of methanol

A technology of pelletizing ore and methanol, which is applied in the direction of electrolysis process and electrolysis components, etc., can solve the problems of great practical value, etc., and achieve the effect of convenient and simple process, less consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

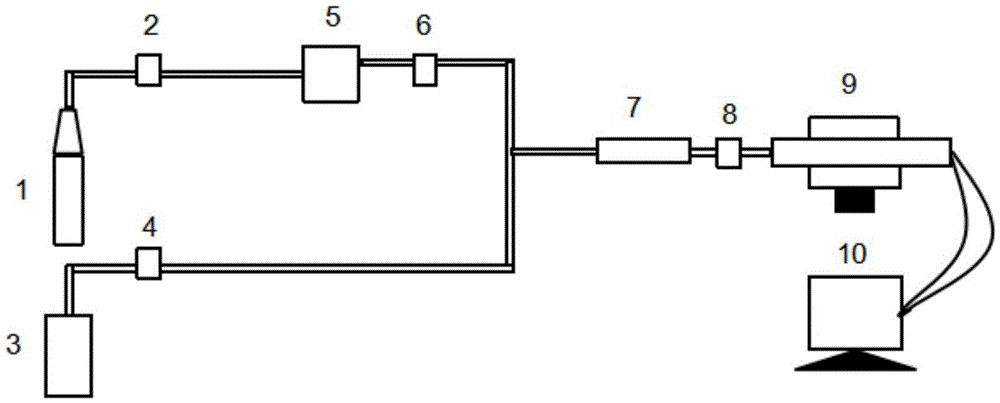

[0032] to combine figure 1 and figure 2 , a process system utilizing methanol to directly reduce pellets in this embodiment consists of nitrogen cylinder 1, No. 1 flow meter 2, hydrogen generator 3, No. 2 flow meter 4, methanol vaporization device 5, No. 3 flow meter 6, It consists of gas mixing valve 7, No. 4 flow meter 8, tubular atmosphere furnace 9 and impedance detection system.

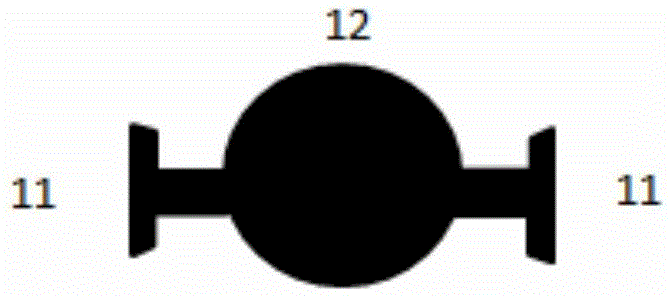

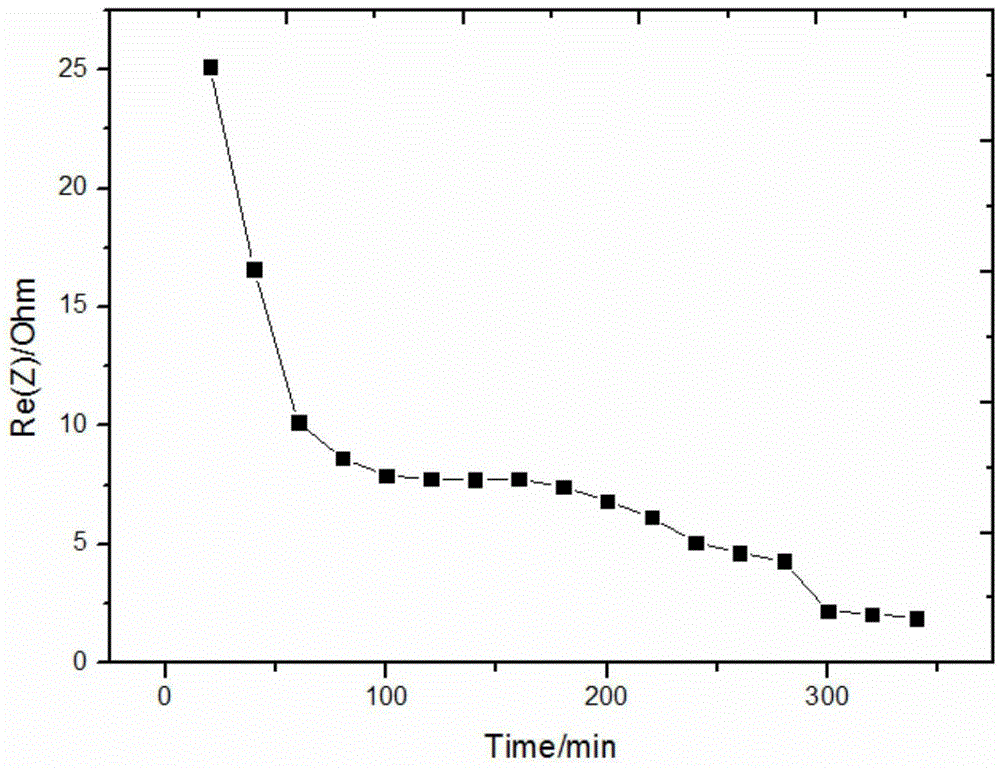

[0033] Grind the pellets into two planes, and drill two holes on the two planes, weigh the mass and record it as 3.659g, screw screws into the two holes, and connect the two wires with the screws. Then, put the pellets in the porcelain boat, put them into the corundum tube of the tube furnace, push the porcelain boat to the center of the corundum tube with a furnace hook, put the alumina furnace plug in a proper position, and keep the two wires from touching. Lead out from one end and connect to VMP-2 electrochemical workstation. When the tube furnace is heated up to a predetermined temperat...

Embodiment 2

[0036] to combine figure 1 and figure 2 , a process system utilizing methanol to directly reduce pellets in this embodiment consists of nitrogen cylinder 1, No. 1 flow meter 2, hydrogen generator 3, No. 2 flow meter 4, methanol vaporization device 5, No. 3 flow meter 6, It consists of gas mixing valve 7, No. 4 flow meter 8, tubular atmosphere furnace 9 and impedance detection system.

[0037] Grind the pellets into two planes and punch holes, and punch two holes on the two planes, weigh the mass and record it as 3.796g, screw screws into the two holes, and connect the two wires with the screws. Then, put the pellets in the porcelain boat, put them into the corundum tube of the tube furnace, push the porcelain boat to the center of the corundum tube with a furnace hook, put the alumina furnace plug in a proper position, and keep the two wires from touching. Lead out from one end and connect to VMP-2 electrochemical workstation. When the tube furnace is heated up to a predet...

Embodiment 3

[0040] to combine figure 1 and figure 2 , a process system utilizing methanol to directly reduce pellets in this embodiment consists of nitrogen cylinder 1, No. 1 flow meter 2, hydrogen generator 3, No. 2 flow meter 4, methanol vaporization device 5, No. 3 flow meter 6, It consists of gas mixing valve 7, No. 4 flow meter 8, tubular atmosphere furnace 9 and impedance detection system.

[0041] Grind the pellets into two planes and punch holes, and punch two holes on the two planes, weigh the mass and record it as 3.574g, screw screws into the two holes, and connect the two wires with the screws. Then, put the pellets in the porcelain boat, put them into the corundum tube of the tube furnace, push the porcelain boat to the center of the corundum tube with a furnace hook, put the alumina furnace plug in a proper position, and keep the two wires from touching. Lead out from one end and connect to VMP-2 electrochemical workstation. When the tube furnace is heated up to a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com