In-situ detection system for residual stress, and detection method thereof

A residual stress, in-situ detection technology, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of inability to perform in-situ detection, repeated unloading of workpieces, and inability to guarantee X-ray residual stress analyzer detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Here, the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

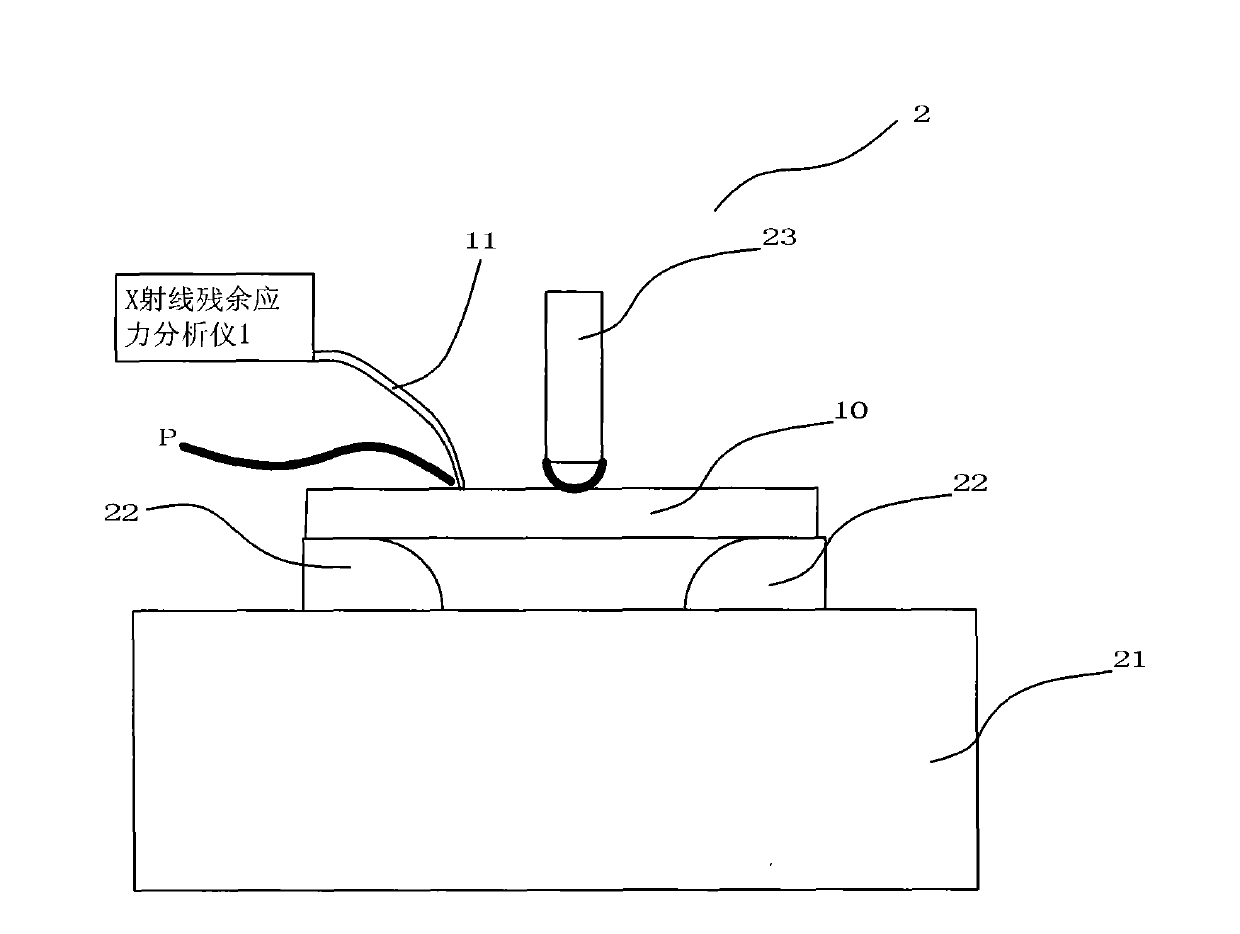

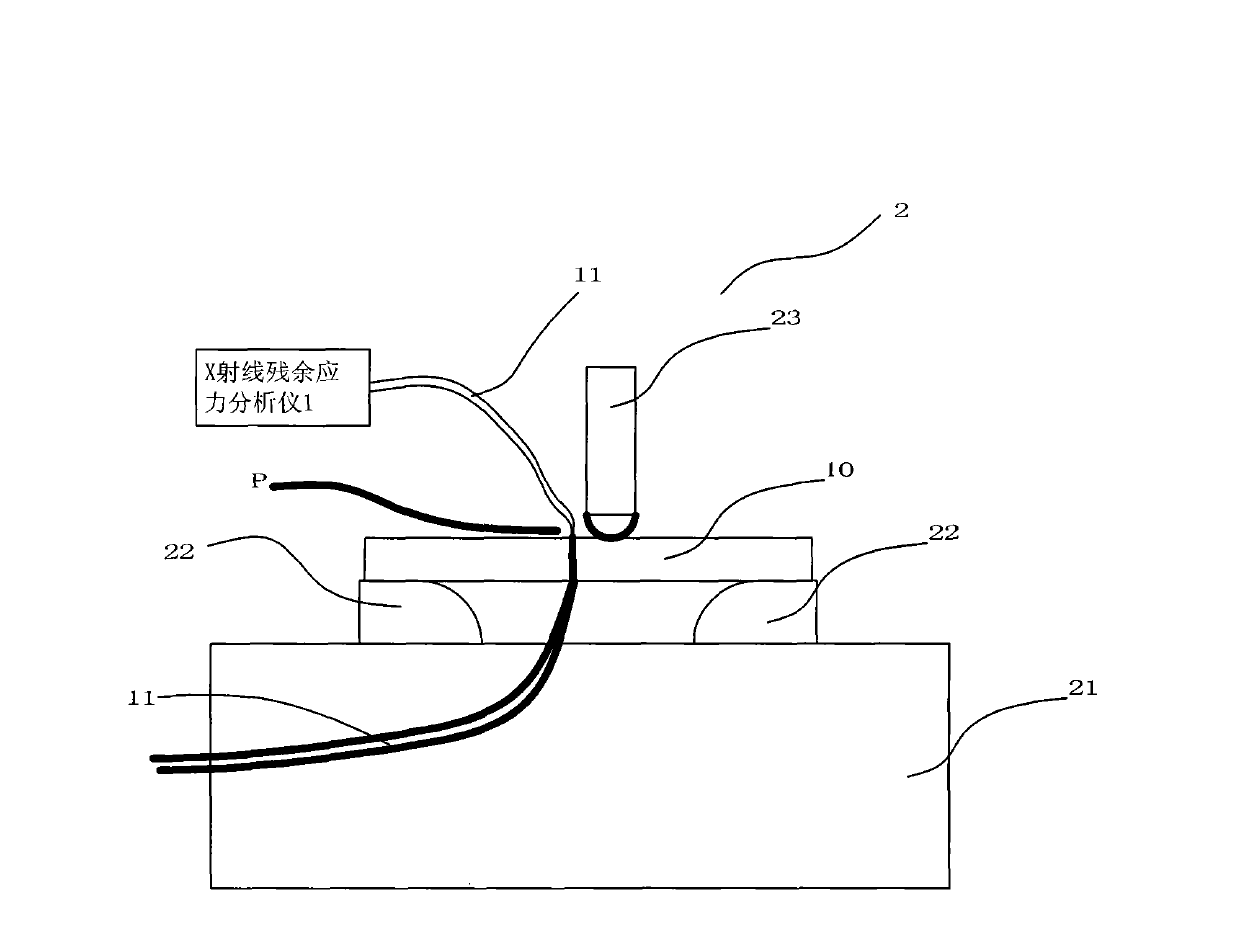

[0021] like figure 1 As shown, the residual stress in-situ detection system of the present invention mainly includes an X-ray residual stress analyzer 1 and a workpiece force application test bench 2 . The X-ray residual stress analyzer 1 is equipped with an X-ray emitting gun 11 , and detects the residual stress at a detection point through the X-ray emitting gun 11 . The workpiece force test stand 2 includes a stand 21 , a workpiece holder 22 , a force application head 23 , and a drive mechanism not shown. The stand 21 is used to support and fix the workpiece holder 22 . The workpiece support 22 is used to support the inspected workpiece 10 . The driving mechanism not shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com