Device and method for detecting disc repairing period of polishing die

A technology for detecting devices and polishing molds, which is applied in the direction of grinding devices, grinding/polishing equipment, and parts of grinding machine tools, etc., which can solve problems such as inconsistent wear of polishing molds, increased polishing costs, and waste of polishing mold repairs. Achieve the effects of improving processing efficiency and processing quality, ensuring grinding activity, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment, but should not limit the transformation range of the present invention with this.

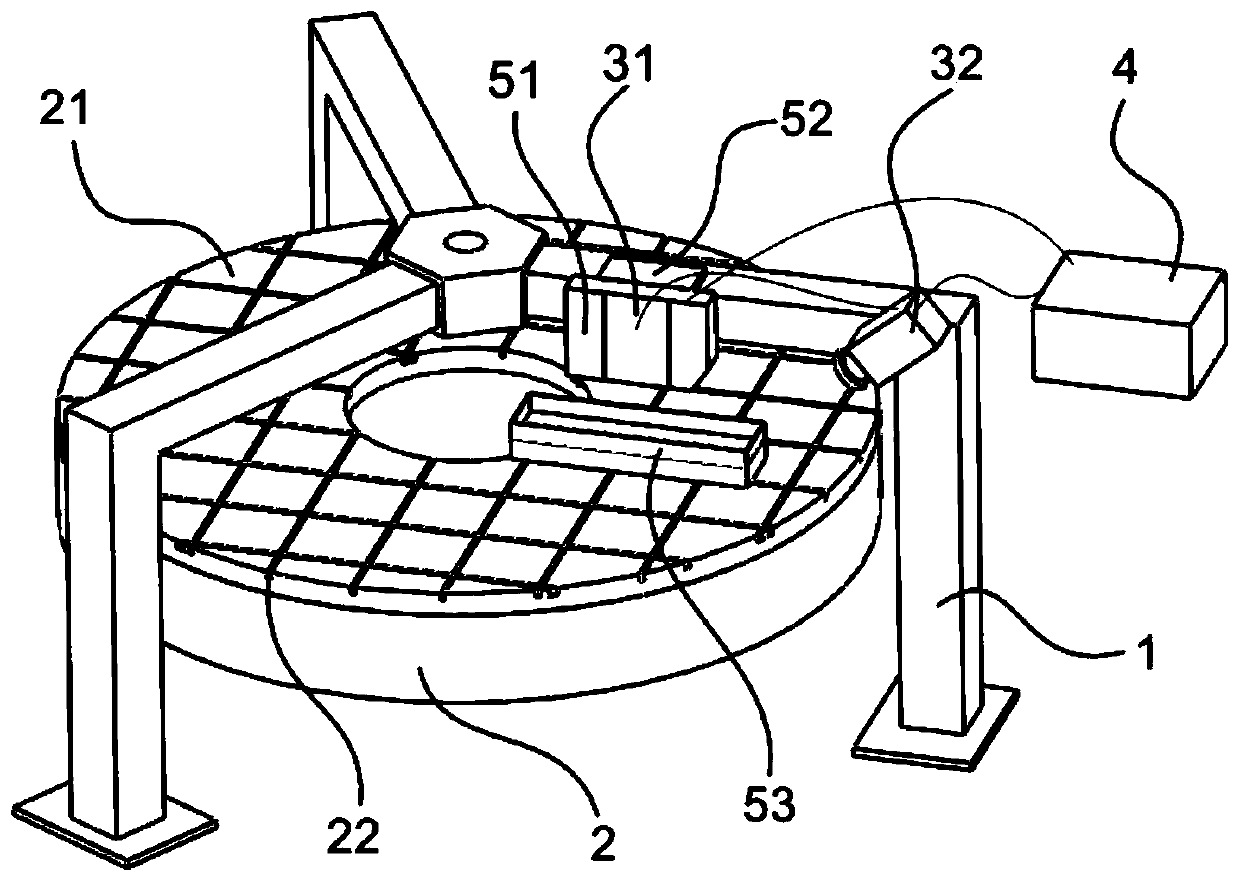

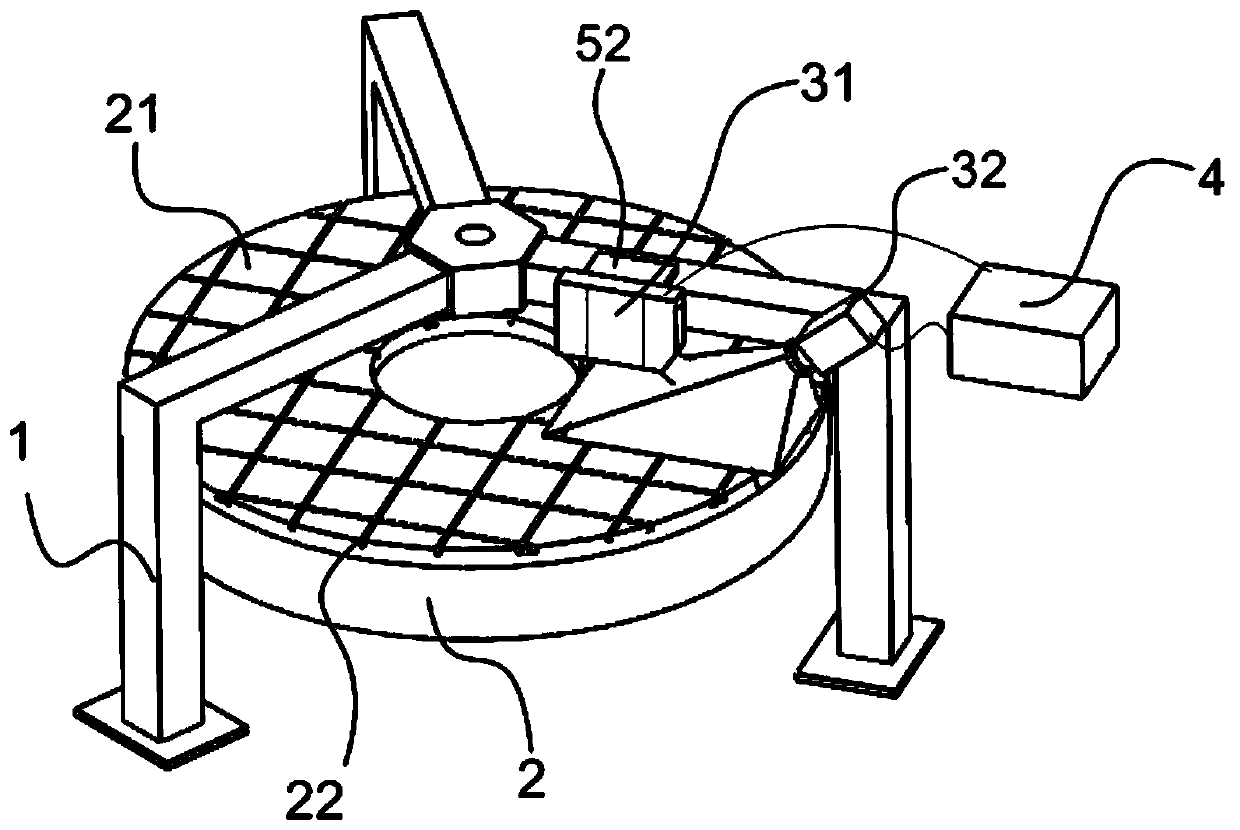

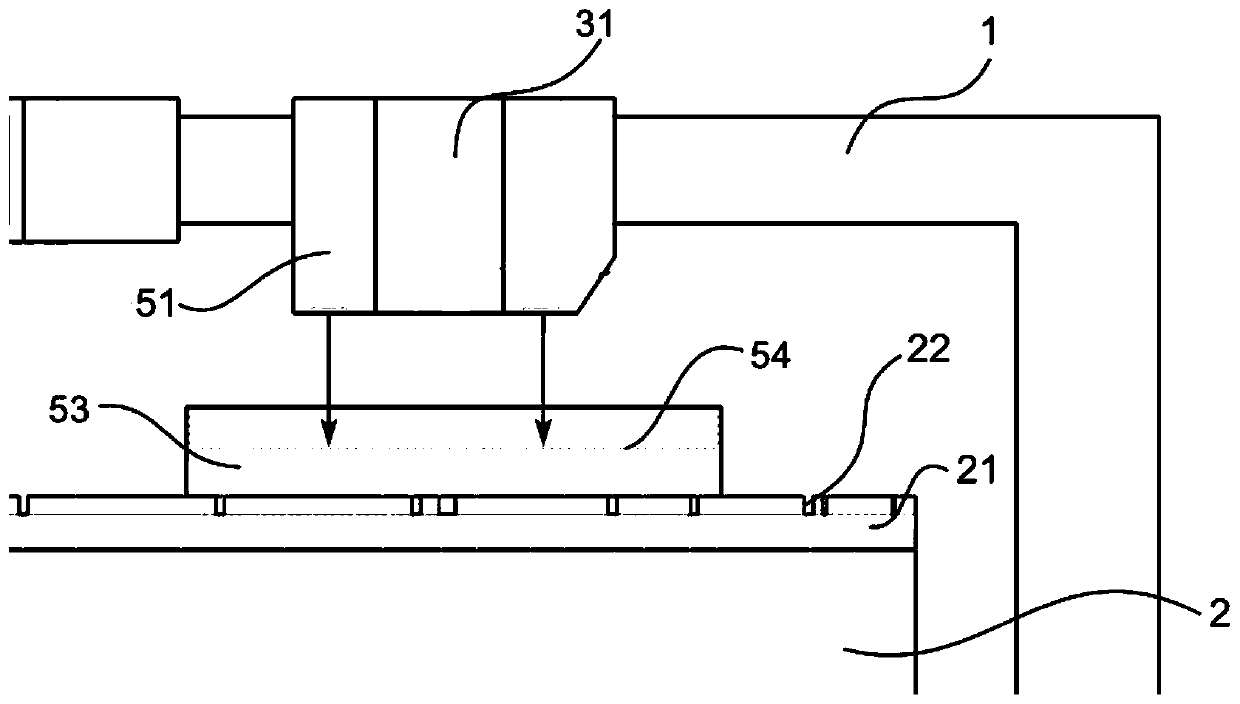

[0038] refer to figure 1 , figure 1 It is a detection device for a polishing mold disk repair cycle of the present invention, comprising: a polishing disk 2, the polishing disk 2 is a disc or an annular disk, a polishing mold 21 cast or pasted on the surface of the polishing disk 2, the polishing There is a groove 22 on the surface of the mold 21; the frame 1 located above the polishing disc 2 and fixedly connected to the ground; it is characterized in that it also includes an optical detection component for detecting the surface topography of the polishing mold 21 3. A processor 4, and a levelness measurement component 5 for measuring the horizontal installation error of the light source 31;

[0039]The levelness measurement assembly 5 includes: a laser displacement sensor 51, a connecting seat 52, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com