Gasification reactor with partial heat recovery device and gasification method by using gasification reactor

A technology of waste heat recovery device and gasification reactor, applied in gasification device details, granular/powdered fuel gasification, chemical industry, etc., to achieve the effects of improved stability and reliability, improved system efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

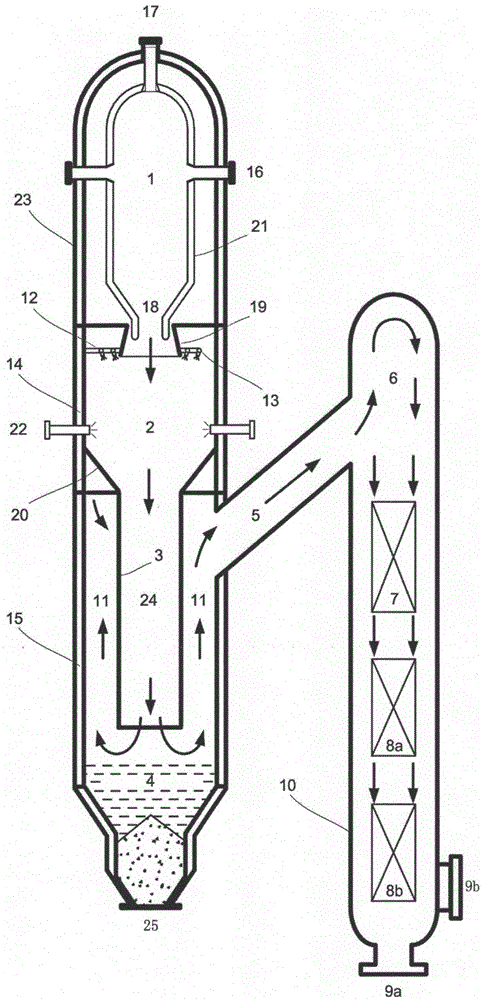

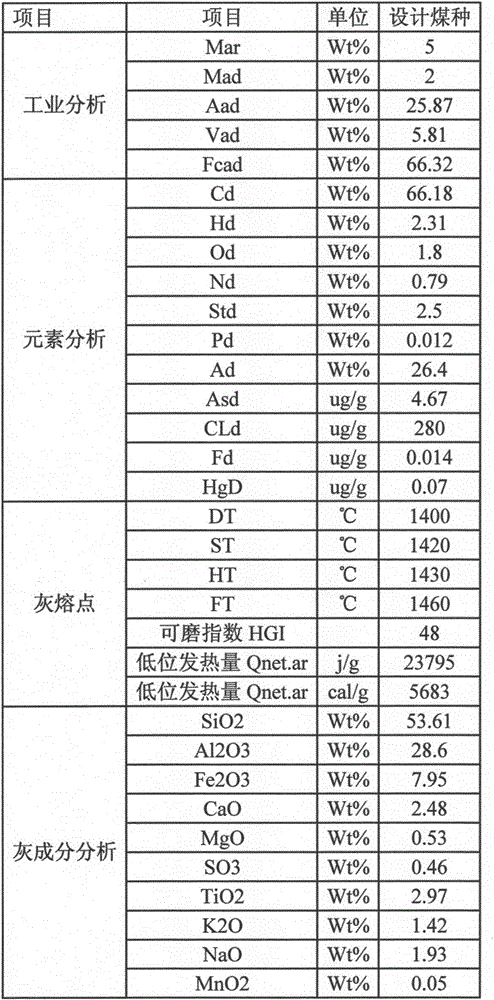

[0053] A set of dry coal powder pressurized gasification reactor with partial waste heat recovery device for processing 3,000 tons of coal per day. The inner diameter of the gasification reaction chamber shell (that is, the water wall 21 of the furnace liner) is 3230 mm, and the inner diameter of the slag discharge port is 25 mm. 1100mm. A layer of four side burner chambers 16 is evenly arranged on the upper side of the gasification furnace. The plane of the side burners is perpendicular to the gasification reaction chamber, the axis is perpendicular, and the radial deflection angle is 4.0°. Enter 100% pulverized coal, 100% water vapor and 100% pure oxygen, and the top burner chamber 17 is used as an ignition / start-up oven burner.

[0054] The cylinder diameter of the chilling conversion chamber 2 is 4150mm. There is one layer of chilling ring 12, and 88 chilling nozzles 13 are evenly arranged along the chilling ring 12 to spray atomized water vapor at 170°C. The nozzle 13 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com