Method for preparing cyclopentanone by using cyclopentene as raw material

A technology for cyclopentene and cyclopentanone, applied in the field of preparing cyclopentanol, can solve the problems of increased energy consumption in post-processing, difficulty in separation, reduced selectivity, etc., and achieves reduction of solvent recovery and purification procedures, simplification of separation and purification system, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1-5

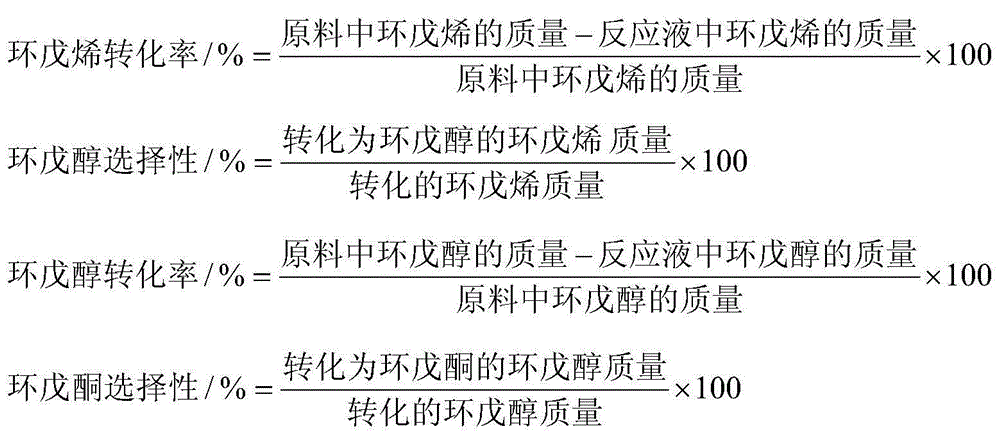

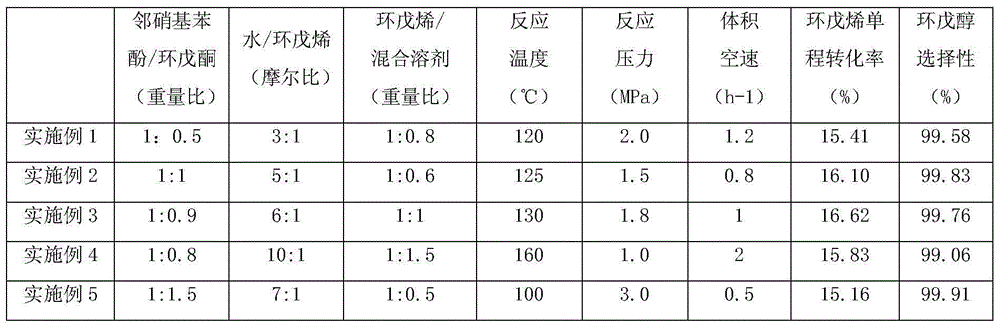

[0020] 1) The material composed of cyclopentene, water, and mixed solvents is continuously hydrated through a fixed bed filled with a catalyst. The catalyst is a strongly acidic cation exchange resin, and its surface is anchored with sulfonic acid groups (purchased from Tianjin Weide International Trade Co., Ltd. company, trade name Amberlyst35), the reaction temperature is 100 ~ 160 ℃, the reaction pressure is 1.0 ~ 3.0MPa, the volume space velocity is 0.5 ~ 2hr -1 ; Wherein: the mixed solvent is composed of o-nitrophenol and cyclopentanone with a mass ratio of 1:(0.5~1.5); the molar ratio of the water and cyclopentene is (3.0~10.0):1, the The weight ratio of cyclopentene and mixed solvent is 1: (0.5~1.5);

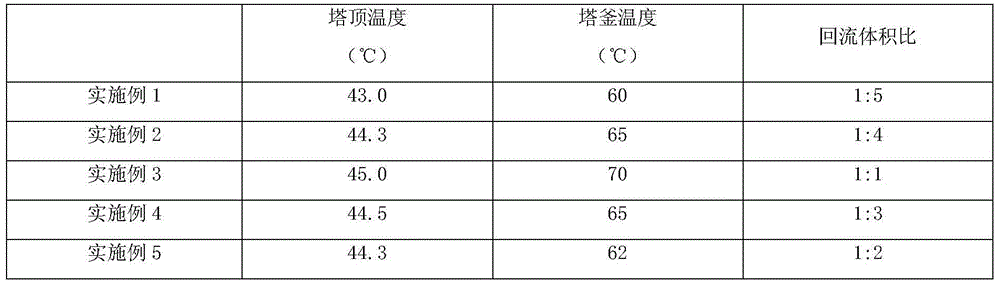

[0021] 2) The hydrated product is separated through a raw material recovery tower, the temperature of the tower reactor is controlled at 60-70° C., and the reflux volume ratio is controlled at 1-5. The heavy component material comes out from the bottom of the tower, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com