A kind of activated sludge for treating high-salt and phenol-containing wastewater and its application

A technology of activated sludge and phenolic wastewater, applied in the direction of water pollutants, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of waste of water resources, easy blockage of ion exchange resin, regeneration cost, high cost, etc., to achieve The effect of efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

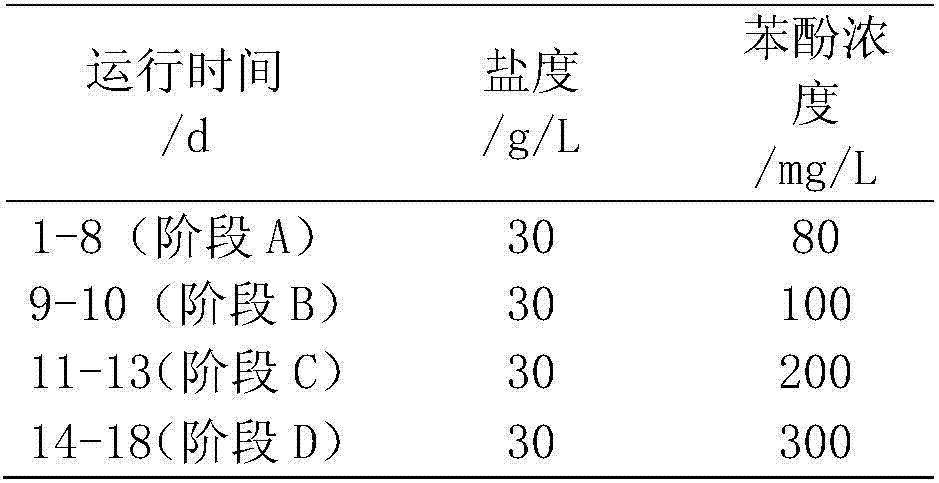

[0011] The sludge comes from the residual sludge in the wastewater biological treatment stage of Shanghai Gaoqiao Petrochemical Plant. In the phase of sludge phenol directional cultivation, the starting temperature of the sequencing batch activated sludge (SBR) reactor is 24±3°C, the initial biomass of the reactor is 6070mg / L MLSS, the hydraulic retention time is 24h, and the influent phenol concentration is 80mg / L. The concentration of simulated wastewater NaCl is 30g / L, KH 2 PO 4 The concentration is 2.65g / L, NH 4 Cl concentration is 0.5g / L, FeCl 2 4H 2 O concentration is 0.01g / L, CaCl 2 The concentration is 0.02g / L, MgSO 4 ·7H 2 O concentration is 0.2g / L, CuSO 4 The concentration is 0.1g / L, HBO 3 The concentration is 0.1g / L, ZnSO 4 The concentration is 0.1g / L, NaMoO 4 2H 2 O concentration is 0.024g / L, MnCl 2 4H 2 O concentration is 0.006g / L, NiCl 2 ·6H 2 O concentration is 0.75g / L, CoCl 2 ·6H 2 The O concentration was 0.19g / L, and the initial concentration...

Embodiment 2

[0016] The operation process is the same as in Example 1. When the salinity is 100g / L NaCl, the SBR reactor can completely degrade 200mg / L of phenol in 2 days.

Embodiment 3

[0018] The operation process is the same as in Example 1. When the salinity is 120g / L NaCl, the SBR reactor can completely degrade 200mg / L of phenol within 4 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com