Laser cleaning equipment

A technology of laser cleaning and equipment, which is applied in the field of laser applications, can solve the problems of low cleaning efficiency and insufficient precision, and achieve the effect of large-format cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

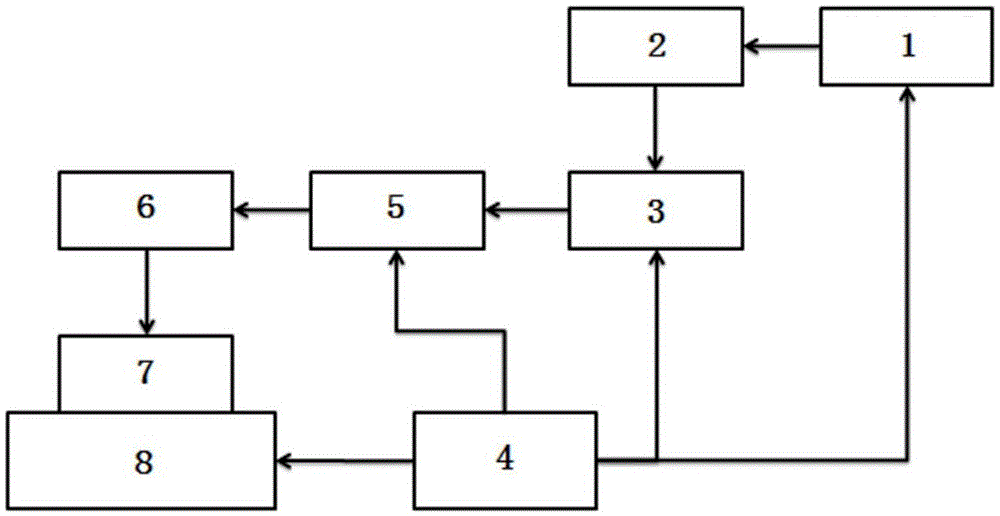

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

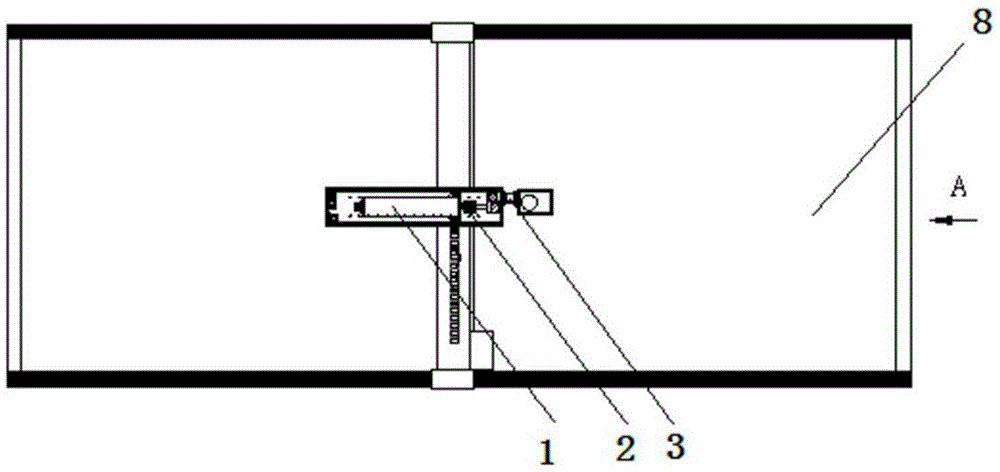

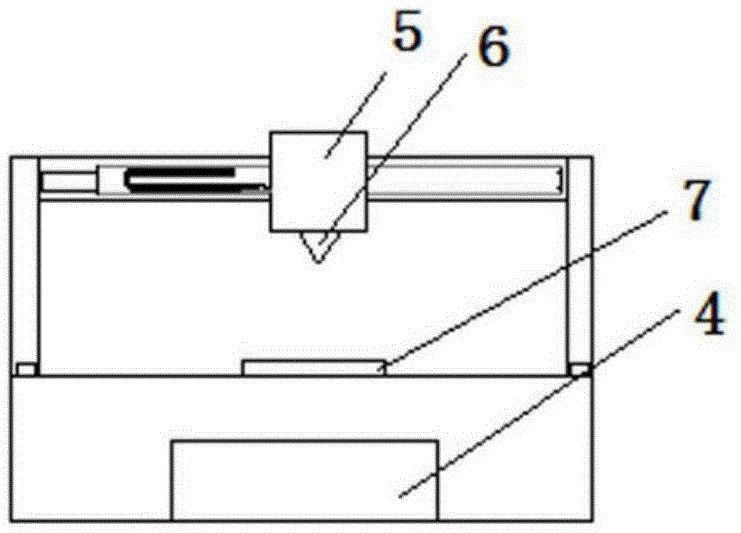

Embodiment Construction

[0034] The principle of laser cleaning machine is to use high-energy laser focused on the surface of pollutants to ablate and gasify pollutants without damaging the workpiece body. For example, glue, dust, grease and other non-metallic materials have a high absorption rate of laser light, while the workpiece body absorbs laser light less, or the workpiece body absorbs laser light but the body is larger than the pollutants, and the heat dissipation is faster, without damaging the workpiece body , while the pollutants are gasified. The present invention proposes a cleaning device using a high-energy laser (which can be about 1 μm, or 10.6 μm, or a laser with other wavelengths). In addition, different wavelength lasers can be replaced according to different pollutants and workpiece materials. Metals, some plastics such as PT, PC, PE, etc., and paper objects can be cleaned with a 10.6 μm wavelength laser, while some objects can be cleaned with a 1 μm wavelength laser, and some sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com