Self-cleaning method of high-temperature filtering system and high-temperature filtering system

A filtration system and self-cleaning technology, applied in separation methods, membrane filters, dispersed particle filtration, etc., can solve problems such as danger, valve damage, inability to effectively close valves, etc., to achieve automatic cleaning, simple and accurate methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

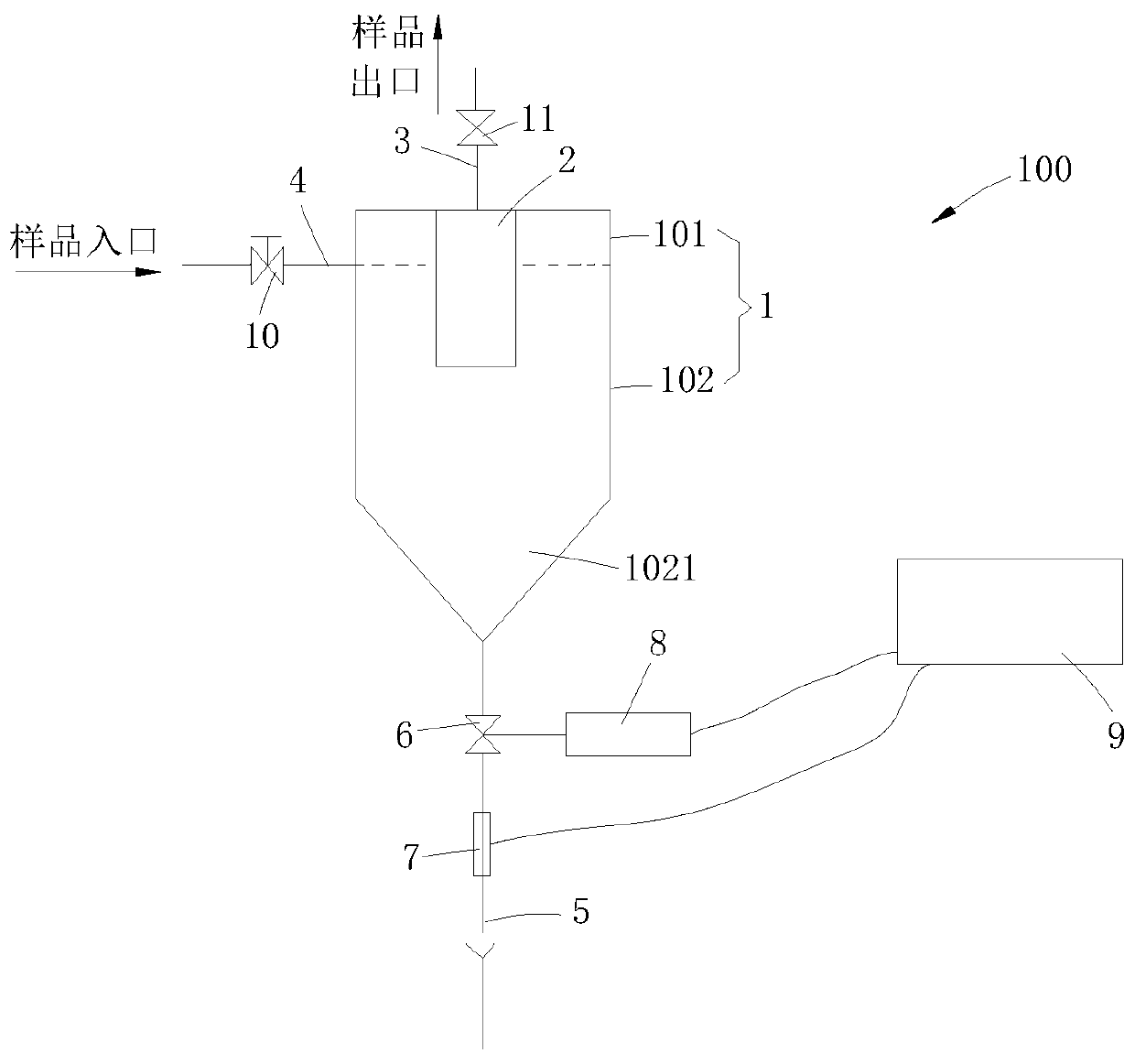

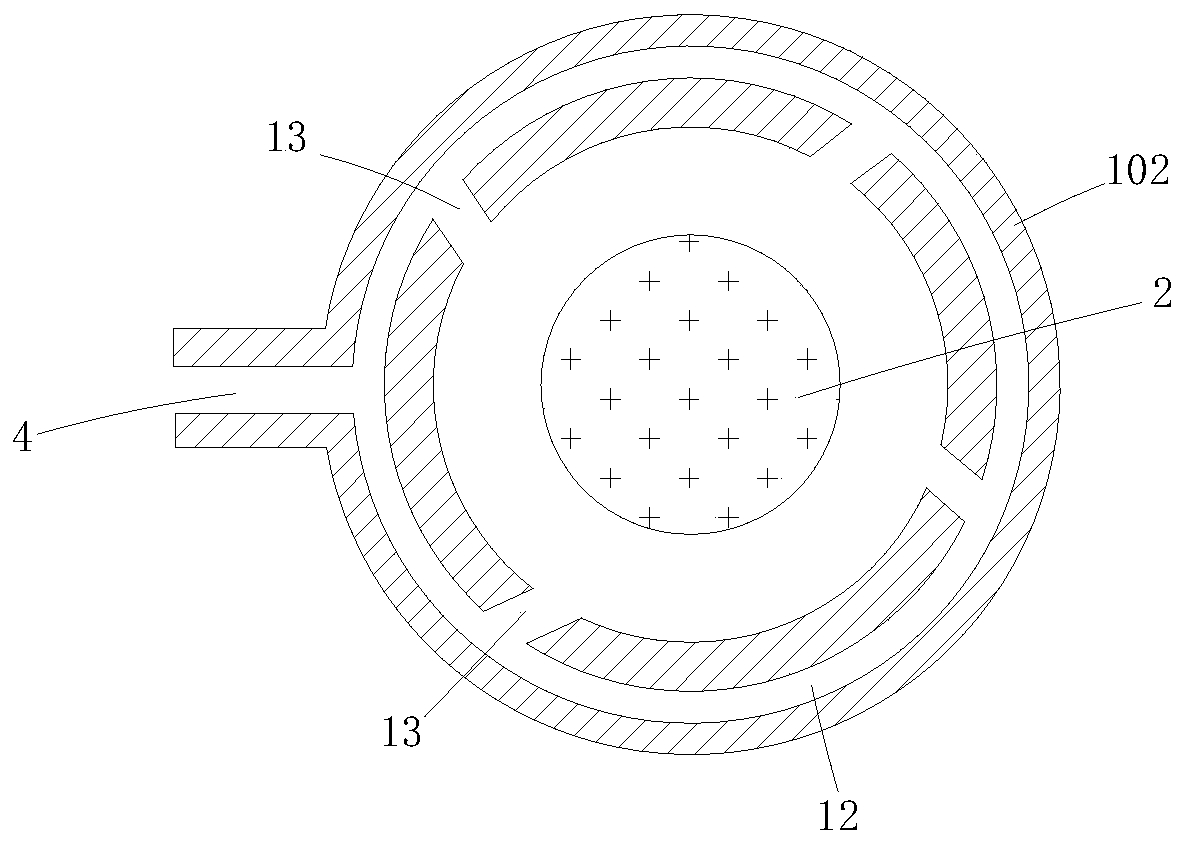

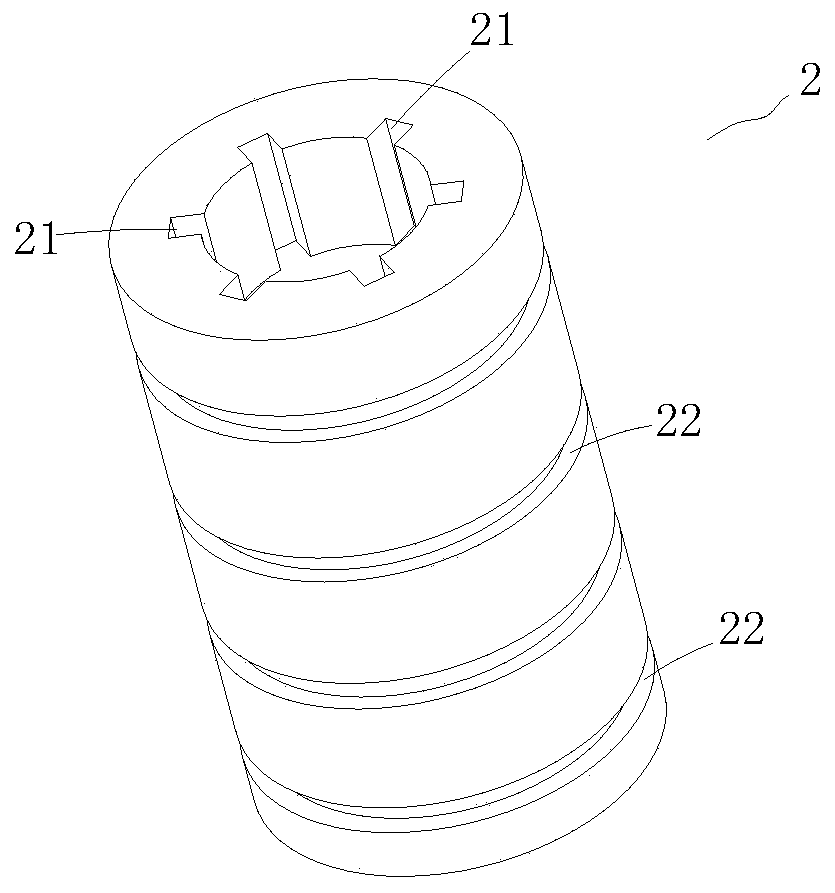

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The present invention aims at the defects that in the existing soda sampling rack, the filter needs to be replaced regularly, and at the same time, a large amount of impurities will accumulate in the cavity where the filter is installed, and regular manual sewage needs to be discharged. A self-cleaning high-temperature filter system cleaning method and high-temperature filter system are proposed. The cleaning method can realize automatic cleaning of high-temperature filter elements, so as to realize long-term maintenance-free operation of high-temperature filter elements.

[0026] First of all, this embodiment provides a self-cleaning high-temperature filter system cleaning method, which aims at the defect that the existing filter has an increased amount of maintenance during use and easily leads to leakage in the later stage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com