Double-regulation flow distribution type efficient separator

A separator and shunt-type technology, applied in the field of separators, can solve the problems of poor powder uniformity, poor adjustment effect of radial baffles, increased energy consumption, etc., achieve good powder uniformity at the outlet, solve poor adjustment performance, increase The effect of regulatory capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

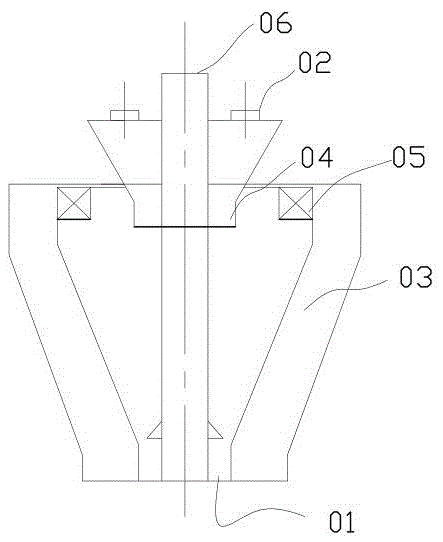

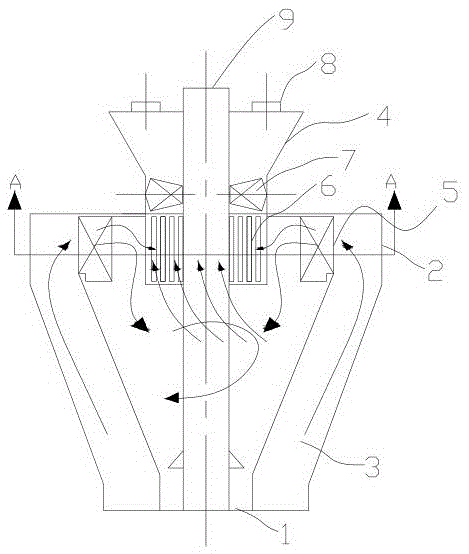

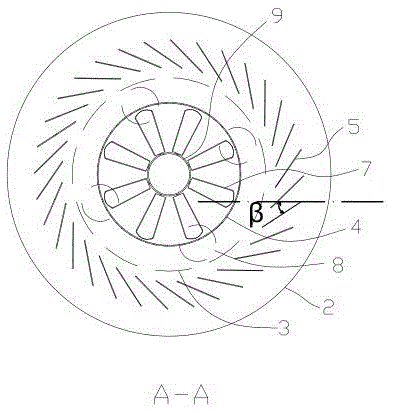

[0024] combined with figure 2 to attach Figure 5 , a dual-adjustment split-flow high-efficiency separator, which includes air powder inlet 1, separator shell 2, separator inner cone 3, distributor 4, radial vanes 5, axial vanes 7, air powder outlet 8 and inlet Material pipe 9; the air powder inlet 1 is located at the small-diameter end of the separator inner cone 3; the separator inner cone 3 is installed in the separator housing 2; the described feed pipe 9 is inserted into the separator Inside the inner cone 3; the distributor 4 is sleeved on the feed pipe 9, the distributor 4 is funnel-shaped, and the vertical section at the bottom of the distributor 4 is provided with several slit structures 6; The slit structure 6 is distributed along the circumference, and the slit of the slit structure extends along the axial direction of the distributor 4; the radial vane 5 is located at the large-diameter end of the separator inner cone 3, and the radial vane 5 is located along the...

specific Embodiment 2

[0025] further combined with Figure 6 , a dual-adjustment split-flow high-efficiency separator, which includes air powder inlet 1, separator shell 2, separator inner cone 3, distributor 4, radial vanes 5, axial vanes 7, air powder outlet 8 and inlet Material pipe 9; the air powder inlet 1 is located at the small-diameter end of the separator inner cone 3; the separator inner cone 3 is installed in the separator housing 2; the described feed pipe 9 is inserted into the separator Inside the inner cone 3; the distributor 4 is sleeved on the feed pipe 9, the distributor 4 is funnel-shaped, and the vertical section at the bottom of the distributor 4 is provided with several slit structures 6; The slit structure 6 is distributed along the circumference, and the slit of the slit structure extends along the axial direction of the distributor 4; the radial vane 5 is located at the large-diameter end of the separator inner cone 3, and the radial vane 5 is located along the separator T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com