Composite filter element and preparation method thereof

A filter, a pair of technology, applied in the field of materials, can solve the problems affecting the service life of activated carbon adsorption function products, the adhesion fastness of activated carbon particles is easy to be insufficient, the adsorption efficiency and filtration effect are reduced, etc. Excellent performance and long adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

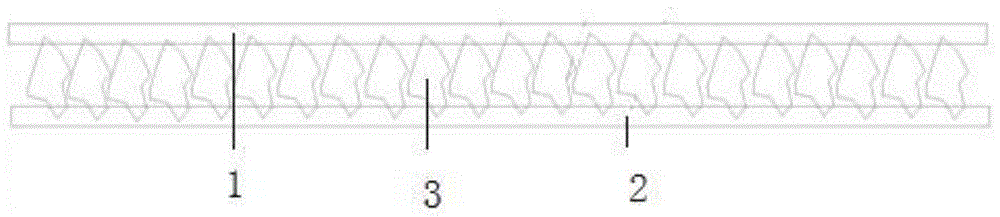

[0021] The composite filter disc comprises an upper layer of non-woven fabric 1, a lower layer of non-woven fabric 2 and a middle layer of activated carbon particles 3; 2 The average fineness of the fiber is 1-5μm, and the weight is 8-25g / m 2 ; The activated carbon particles in the middle layer 3 are irregular particles and the weight accounts for 95%-97% of the total weight of the material.

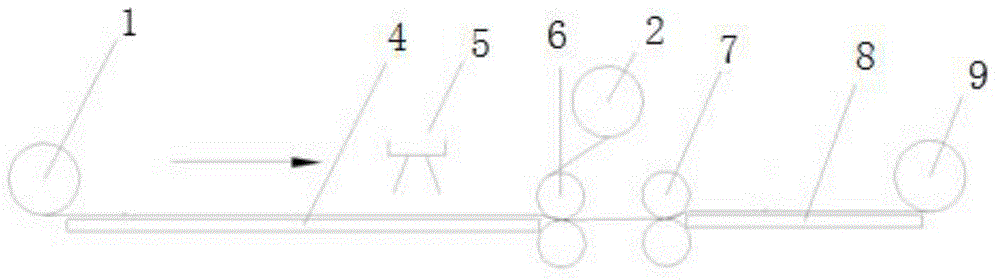

[0022] See figure 1 and figure 2 To prepare a raw material roll of melt-blown cloth with a gram weight of 10g, first spread the lower layer of non-woven fabric 2 on the raw material feeding plate 4, and evenly spread the middle layer of activated carbon particles 3 with a diameter of 1mm on the raw material feeding plate through the vibrating screen 5. The input plate 4 is covered with the upper layer of non-woven fabric 1, and the preparation is rolled by a pair of heatable rubber rollers 6 at 55 degrees Celsius, and then transported to the material output plate 8 by a pair of rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average fineness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com