Program-controlled electromagnetic induction heating device and method for processing waste battery by using device

A technology of electromagnetic induction heating and waste batteries, applied in the direction of induction heating, battery recycling, recycling technology, etc., can solve the problems of air pollution, affecting people's health, animal and plant growth, harsh environmental effects, etc., and achieve high heating efficiency and uniform heating , The effect of low separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

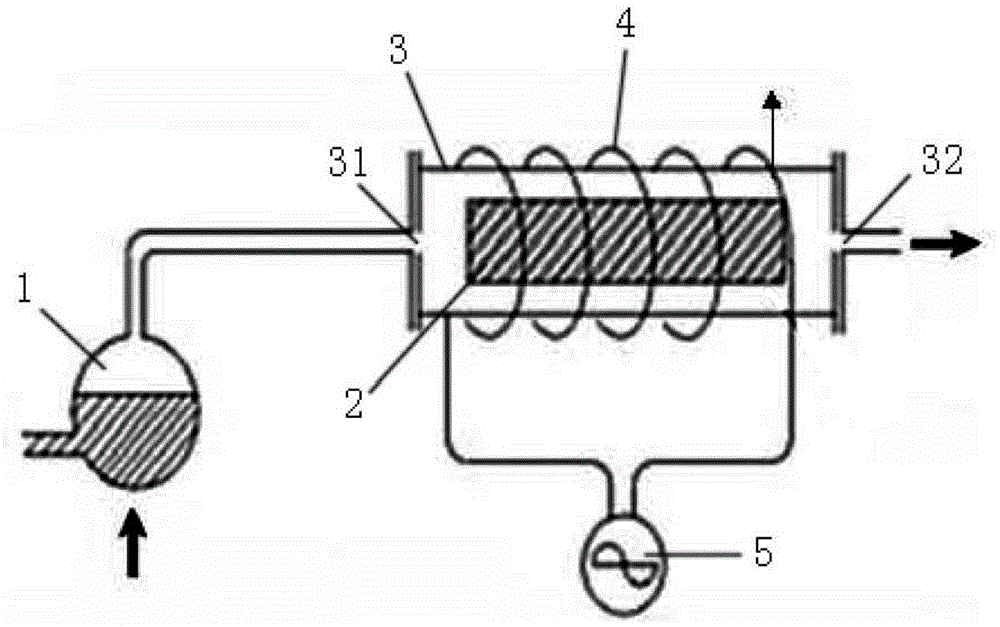

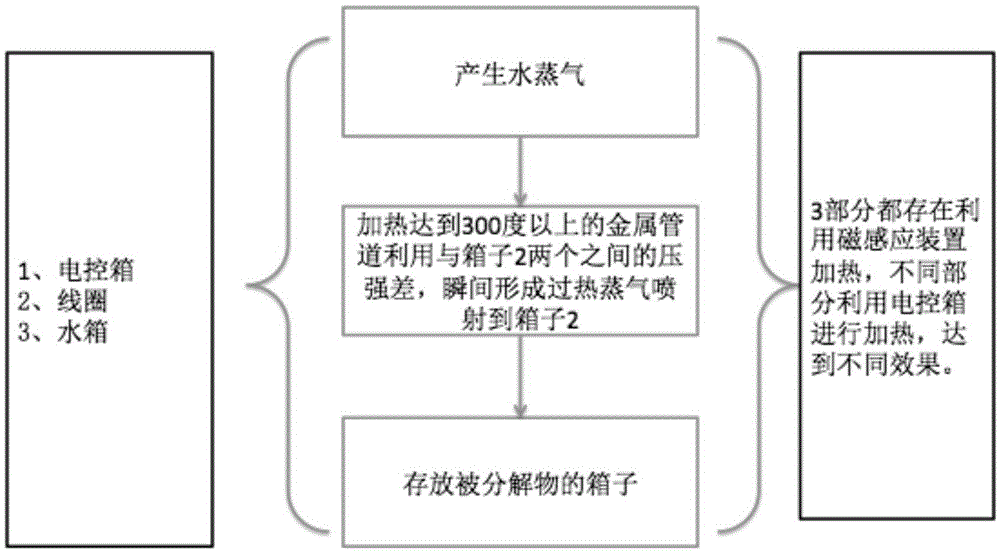

[0027] A program-controlled electromagnetic induction heating device, comprising a water tank 1, a metal pipe 3 and a storage box 2, the two ends of the metal pipe 3 are respectively provided with a steam inlet 31 and a steam outlet 32, and the steam inlet 31 is connected to the water tank 1 connected, the outside of the metal pipe 3 is evenly wound with a coil 4, and the two ends of the coil 4 are connected to the electric control box 5; the storage box 2 is arranged in the metal pipe 3, and a plurality of through holes (not shown).

[0028] Preferably, the coil 4 wound outside the metal pipe 3 is a high-frequency coil.

[0029] Preferably, the containing box 2 is rectangular, it is located in the middle of the metal pipe 3 and its length direction is parallel to the axial direction of the metal pipe 3 . It should be noted, figure 1 container in the figure 2 and image 3 Same for bin 2 in .

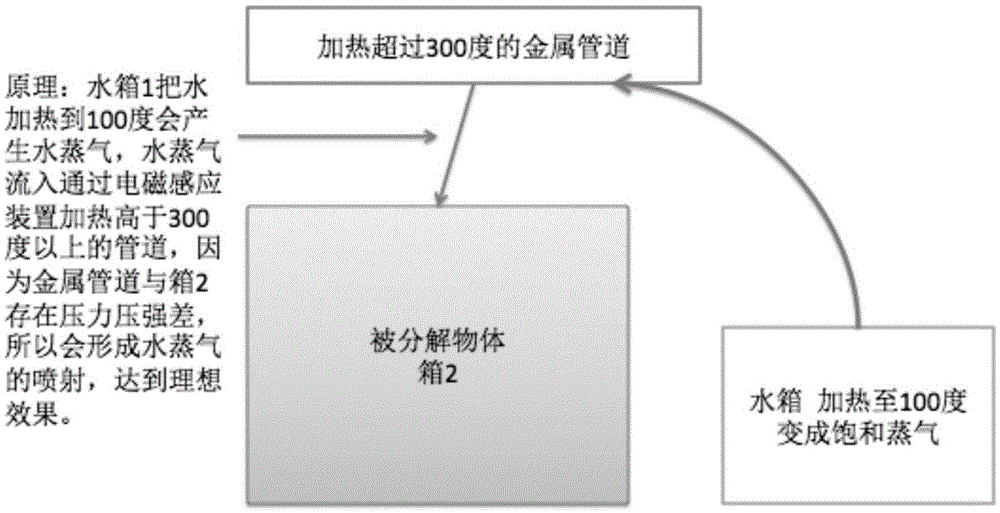

[0030] When the program-controlled electromagnetic induction heating device of...

Embodiment 2

[0032] The method for treating waste batteries by using a program-controlled electromagnetic induction heating device comprises the following steps:

[0033] 1) Put the waste battery in the storage box 2 of the programmable electromagnetic induction heating device in Example 1, turn on the programmable electromagnetic induction heating device, and heat the water in the water tank 1 to generate water vapor;

[0034] 2) Water vapor enters the metal pipe 3 through the steam inlet 31, and under the action of the electrified coil 4, the water vapor is continuously heated to form wet saturated steam at 140°C; continue to heat the wet saturated steam until it turns into dry saturated steam , continue to heat the dry saturated steam to 250 ° C ~ 700 ° C to form superheated steam;

[0035] 3) Maintain the temperature at 250°C to 700°C and the pressure at 0.1 to 1.0Mpa, decompose the organic matter inside the battery, leaving only metal solids in the storage box 2, and other decomposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com