Preparation method of novel nano manganese lithium titanate LiMnxTiO4 cathode material

A technology of lithium manganese titanate, cathode material, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of unsolved battery safety, low material gram capacity, and expensive cobalt source and other problems, to achieve the effects of excellent electrochemical performance, simple preparation process, and regular particle morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of nano-manganese lithium titanate positive electrode material: Weigh 4.196g lithium hydroxide, 14.295g manganese oxalate, 28.422g tetrabutyl titanate in sequence, respectively add to 35g of absolute ethanol and stir to dissolve, then add 2g of PEG2000, Electric stirring 2h until completely dissolved. The solution was transferred to a 50ml Teflon-lined reactor for solvothermal reaction at 170°C for 4h, and then suction filtered, washed, and dried to obtain a lithium manganese titanate precursor. The precursor was calcined at a high temperature of 900°C for 6 hours, cooled and then ground to obtain the nano manganese lithium titanate positive electrode material.

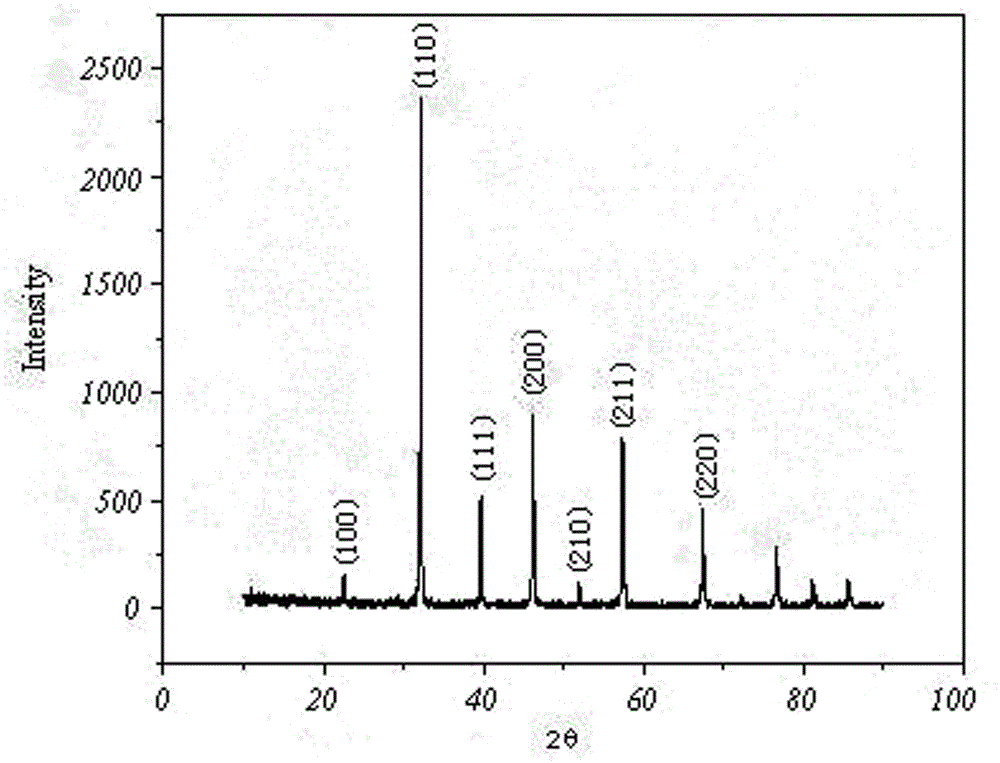

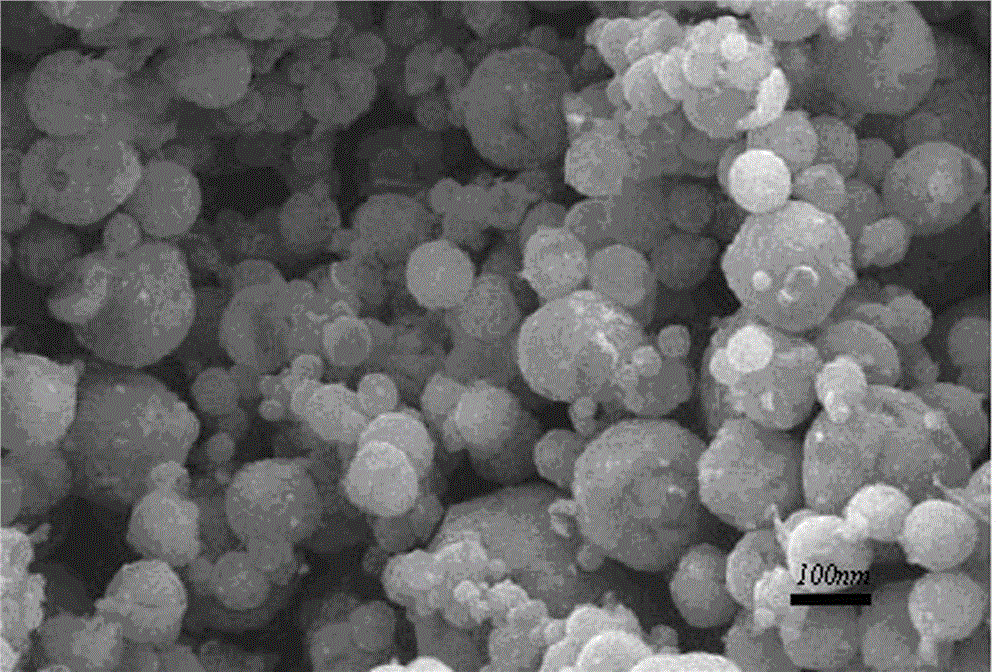

[0026] The prepared materials were tested and analyzed by X-ray diffractometer and scanning electron microscope respectively. figure 1 It can be seen that the characteristic diffraction intensity of the material is strong, so it has a high degree of crystallinity, figure 2 It can be se...

Embodiment 2

[0028] The preparation method of nano-manganese lithium titanate positive electrode material: Weigh 10.2g lithium acetate, 10.38g manganese acetate, 28.42g isopropanol titanate in sequence, add to 25g absolute ethanol and stir to dissolve, then add 1.5g PEG2000, Electric stirring 2h until completely dissolved. The solution was transferred to a 50ml Teflon-lined reactor for solvothermal reaction at 90°C for 12 hours, and then suction filtered, washed, and dried to obtain a lithium manganese titanate precursor. The precursor was calcined at a high temperature of 650°C for 12 hours, cooled and then ground to obtain the nano manganese lithium titanate positive electrode material.

[0029] Similarly, the X-ray diffractometer and scanning electron microscope are used to test and analyze the prepared material, which shows that the material has strong crystallinity and relatively regular morphology, and the particle size is about 100-200nm. The battery made with this sample has a cap...

Embodiment 3

[0031] The preparation method of nano-manganese lithium titanate positive electrode material: Weigh 7.389g lithium carbonate, 17.3g manganese acetate, 28.42g isopropanol titanate in sequence, add to 25g of absolute ethanol and stir to dissolve, then add 2.2g of PEG2000, Electric stirring 2h until completely dissolved. The solution was transferred to a 50ml Teflon-lined reactor for solvothermal reaction at 120°C for 8 hours, and then suction filtered, washed, and dried to obtain a lithium manganese titanate precursor. The precursor is calcined at a high temperature of 750°C for 10 hours, cooled and then ground to obtain the nano manganese lithium titanate positive electrode material.

[0032] Similar to Examples 1 and 2, X-ray diffractometer and scanning electron microscope were used to test and analyze the prepared material. The test results showed that the material had very good crystallinity and the size was about 150-200 nm. The button cell made of this sample still mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com