Flexible electroluminescence composite material and preparation method thereof

A technology of composite materials and luminescent materials, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of short service life and instability, and achieve the effects of long service life, stable luminescence, and adjustable luminous color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

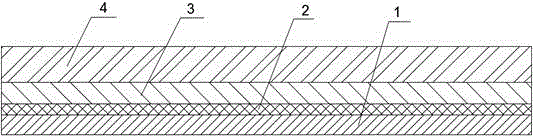

Image

Examples

Embodiment 1

[0033] 1.1 Measure n-hexane and acetone with a volume of 2mL respectively. After mixing evenly, add 5g polyvinylcarbazole under stirring conditions and make it completely dissolve;

[0034] 1.2 Weigh 0.1g of fullerene and add it to the solution obtained in Example 1.1. After mixing evenly, the dielectric layer is coated on the PET film with an ITO conductive layer on the surface by screen printing, and the thickness of the dielectric layer is controlled to be 10 micron, followed by drying;

[0035] 1.3 Add 50g of rare earth red rare earth luminescent material with a particle size of 100nm to the mixed solution of n-hexane and acetone with a volume of 10mL, and stir to make it evenly mixed;

[0036] 1.4 Weigh 49g of polyvinylcarbazole and 1g of graphene into the solution obtained in step 1.3 to obtain a mixed solution;

[0037] 1.5 Use screen printing to evenly coat the solution in Example 1.4 on the dielectric layer in Example 1.2, and control the thickness of the light-emitt...

Embodiment 2

[0040] 2.1 Measure n-hexane and acetone with a volume of 2mL respectively. After mixing evenly, add 5g polyvinylcarbazole under stirring conditions and make it completely dissolve;

[0041] 2.2 Weigh 0.1g of fullerene and add it to the solution obtained in Example 2.1. After mixing evenly, the dielectric layer is coated on the PET film with an ITO conductive layer on the surface by screen printing, and the thickness of the dielectric layer is controlled to be 10 micron, followed by drying;

[0042] 2.3 Add 50g of white rare earth luminescent material with a particle size of 1500nm to the mixed solution of n-hexane and acetone with a volume of 10mL respectively, and stir to make it evenly mixed;

[0043] 2.4 Weigh 25g of polyvinyl carbazole and 1 gram of graphene into the solution obtained in Example 2.3 to obtain a mixed solution;

[0044] 2.5 The solution in Example 2.4 was uniformly coated on the dielectric layer in Example 2.2 by screen printing, and the thickness of the l...

Embodiment 3

[0047] 3.1 Measure n-hexane and acetone with a volume of 2mL respectively. After mixing evenly, add 5g polyvinylcarbazole under stirring conditions and make it completely dissolve;

[0048] 3.2 Weigh 0.1g of fullerene and add it to the solution obtained in Example 3.1. After mixing evenly, the dielectric layer is coated on the PET film with an ITO conductive layer on the surface by screen printing, and the thickness of the dielectric layer is controlled to be 10 micron, followed by drying;

[0049] 3.3 Add 31g of red rare earth luminescent material with a particle size of 1200nm to the mixed solution of n-hexane and acetone with a volume of 10mL, and stir to make it evenly mixed;

[0050] 3.4 Weigh 30 g of polyvinylcarbazole and 1 gram of graphene into the solution obtained in Example 3.3 to obtain a mixed solution;

[0051] 3.5 Laser printing was used to evenly coat the solution in Example 3.4 on the dielectric layer in Example 3.2, and control the thickness of the luminescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com