Quick preparation method for synchrotron radiation X-ray diffraction test sample of hydrogen storage material

A hydrogen storage material and X-ray technology, which is applied in the field of synchrotron radiation X-ray diffraction testing, can solve problems such as easy oxidation, achieve the effects of avoiding oxidation, good light transmission, and improving the success rate of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. In an argon atmosphere glove box, weigh about 1g of LaNi through an electronic balance 5 Pour the sample into an agate mortar and grind it thoroughly until the particle size of the sample powder is between 10 μm and 20 μm. The particle size of the powder is confirmed by SEM, and then 0.04g LaNi is weighed by an electronic balance in an argon atmosphere glove box. 5 Powder samples are loaded into small glass weighing boats for later use.

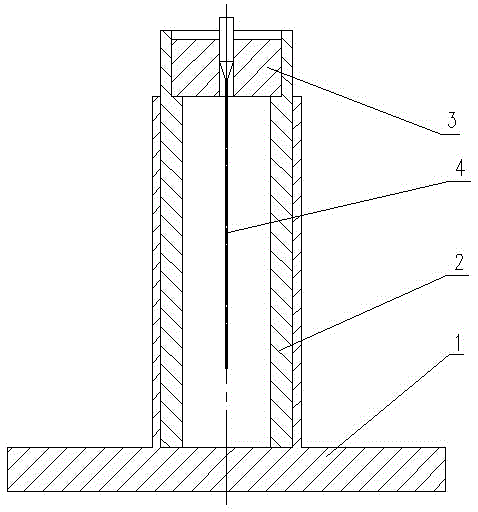

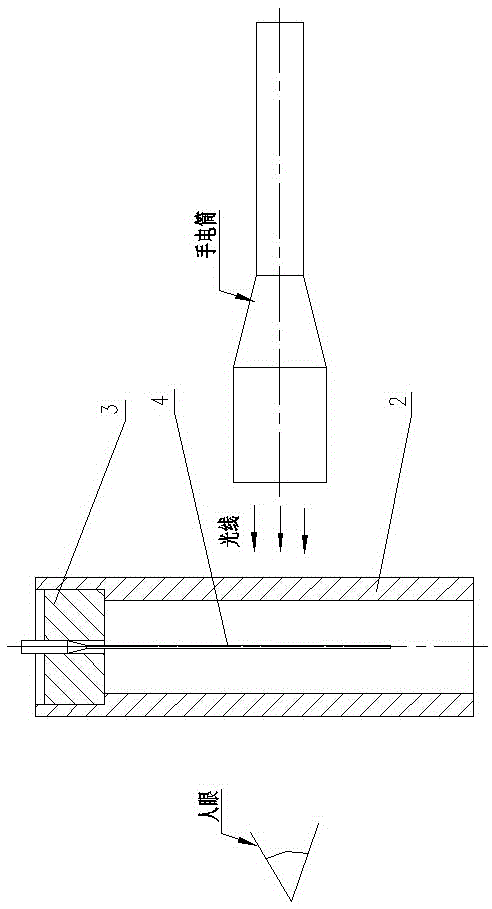

[0021] 2. Move the capillary holder into the argon atmosphere glove box, and insert a paper funnel into the funnel at the upper end of the capillary, then pour all the powder samples in the glass weighing boat into the weighing paper funnel, and use a wire of about 1mm Push the powder sample into the funnel of the capillary.

[0022] After there is no powder sample in the weighing paper funnel, remove the weighing paper funnel, take out the transparent plexiglass tube together with the sponge and the capillary with the funnel at th...

Embodiment 2

[0027] 1. In an argon atmosphere glove box, weigh about 1g of LaNi through an electronic balance 4.75 Al 0.25 Pour the sample into an agate mortar and grind it thoroughly until the particle size of the sample powder is between 10 μm and 20 μm. The particle size of the powder is confirmed by a laser particle size analyzer, and then in an argon atmosphere glove box, weigh 0.035 μm with an electronic balance. The g powder sample is loaded into a small glass weighing boat for use.

[0028] 2. Move the capillary holder into the argon atmosphere glove box, and insert a paper funnel into the funnel at the upper end of the capillary, then pour all the powder samples in the glass weighing boat into the weighing paper funnel, and use a wire of about 1mm Push the powder sample into the funnel of the capillary.

[0029] After there is no powder sample in the weighing paper funnel, remove the weighing paper funnel, take out the transparent plexiglass tube together with the sponge and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com