Heat supply and haze removal all-in-one machine and haze removal method thereof

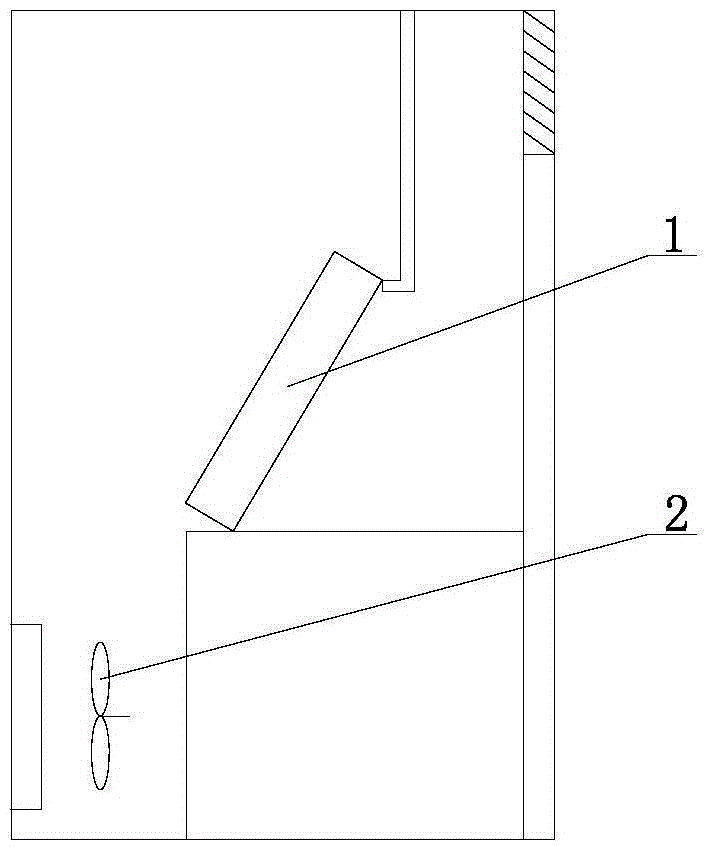

An all-in-one, haze removal technology, applied in heating methods, household heating, space heating and ventilation, etc., can solve problems such as increased fear of haze, and achieve good haze removal effect, fast and thorough defrosting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

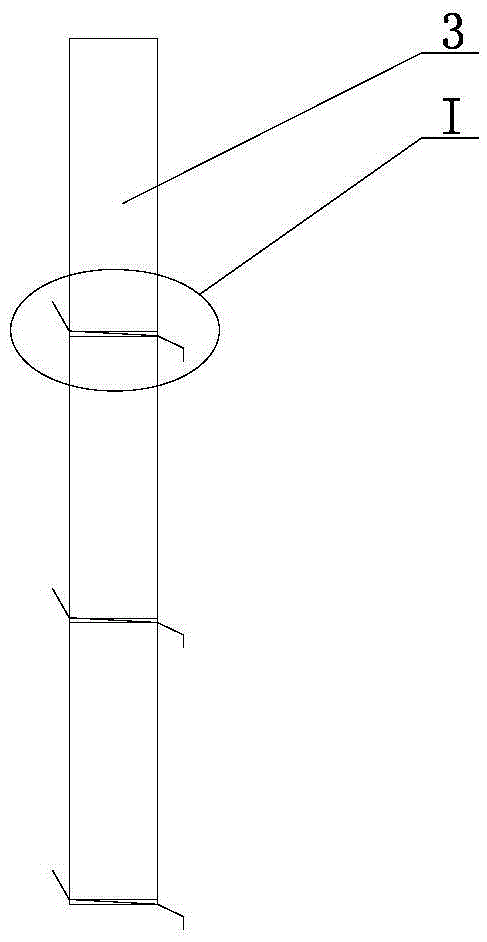

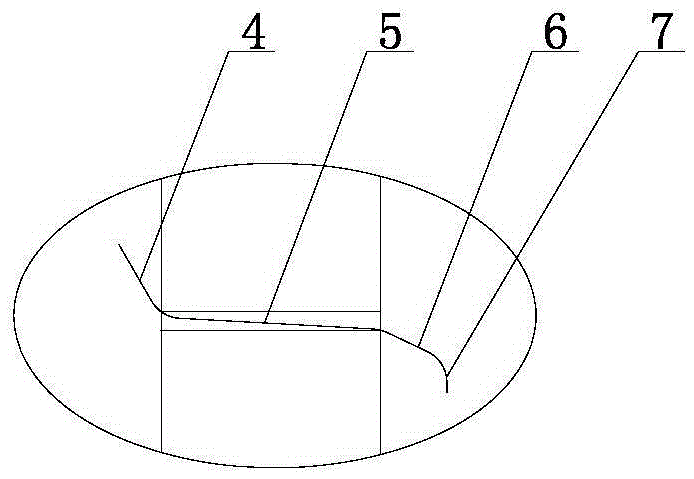

[0032] Such as figure 2 , 3 As shown, the heat exchanger 1 includes 3 sets of heat exchange units 3, and each heat exchange unit 3 is arranged longitudinally from top to bottom, and the heat exchange units 3 are not separated in this embodiment. The upper and lower adjacent two groups of heat exchange units 3 are separated by a partition plate 5, and the partition plate 5 is inclined downward from the inside to the outside; water retention; set water diversion plate 6 on the outside of partition plate 5 (the inclination angle of water diversion plate 6 is not less than the inclination angle of partition plate 5), so as to draw out the water after defrosting quickly and in time, so that the drainage is more thorough; consider Considering the safety factor, the end of the water diversion plate 6 is bent downward to form a safety protection plate 7. Arc transition can be adopted between the above-mentioned upper water retaining plate 4 and the spacer plate 5, between the space...

Embodiment 2

[0034] Such as Figure 4 As shown, the heat exchanger 1 includes 3 sets of heat exchange units 3 , and each heat exchange unit 3 is arranged vertically from top to bottom. In this embodiment, each heat exchange unit 3 is partially staggered. The upper and lower adjacent two groups of heat exchange units 3 are separated by a partition plate 5, and the partition plate 5 is inclined downward from the inside to the outside; the inner side of the partition plate 5 is provided with an upper water barrier 4, and the outer side is provided with a water diversion plate 6, The end of the water guide plate 6 is bent downwards to form a safety protection plate 7 . Arc transition can also be adopted between the upper water retaining plate 4 and the spacer plate 5, between the spacer plate 5 and the water diversion plate 6, and between the water diversion plate 6 and the safety protection plate 7, so as to reduce the resistance to water, which is beneficial to water flow. Discharge in time...

Embodiment 3

[0036] Such as Figure 5 As shown, the heat exchanger 1 includes three sets of heat exchange units 3, and each heat exchange unit 3 is arranged obliquely inward from top to bottom (in the industry, the windward side of the heat exchanger 1 is generally considered to be the outer side), and each set The heat exchange units 3 are completely staggered. In order to be able to discharge the water formed by frost in the defrosting process in time, a water collecting plate 8 is arranged at the bottom of the bottom heat exchange unit 3, and the water collecting plate 8 is inclined downward from the inside to the outside, so that each heat exchange unit 3 Water drips on the water collecting plate 8 at any time, and is discharged from the outdoor unit in time through the drain pipe 9 or other drainage devices.

[0037] Embodiments 1, 2, and 3 all adopt the technical scheme of dividing the heat exchanger 1 into upper and lower sets of heat exchange units 3 for separate drainage, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com