Split type gear pump floating shaft sleeve combination piece and machining method thereof

A floating bushing and gear pump technology, applied in pump components, rotary piston/swing piston pump components, bearing components, etc., can solve the problems of difficult to guarantee the accuracy of parts, high processing rejection rate, and difficult to control product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

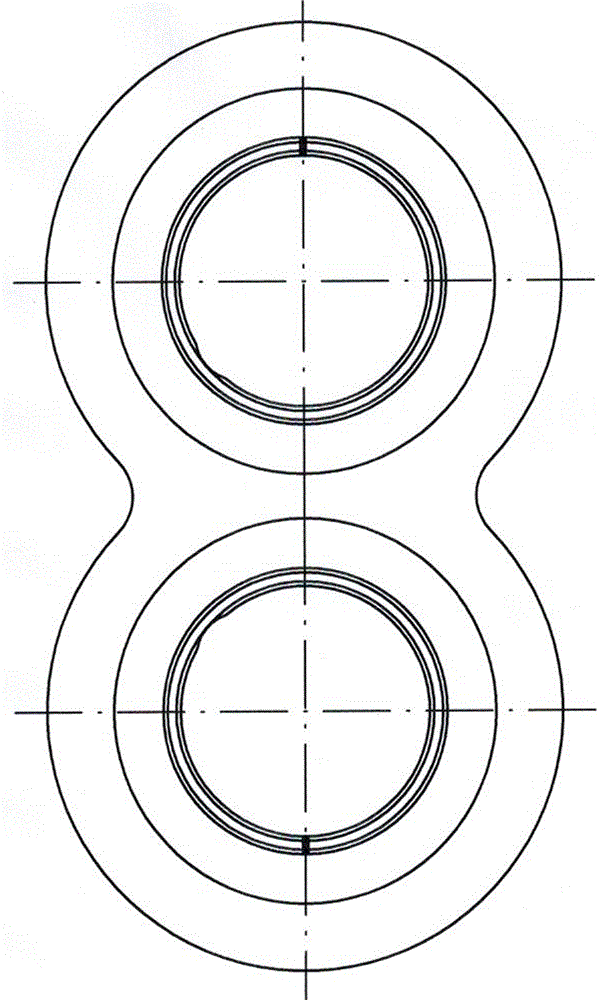

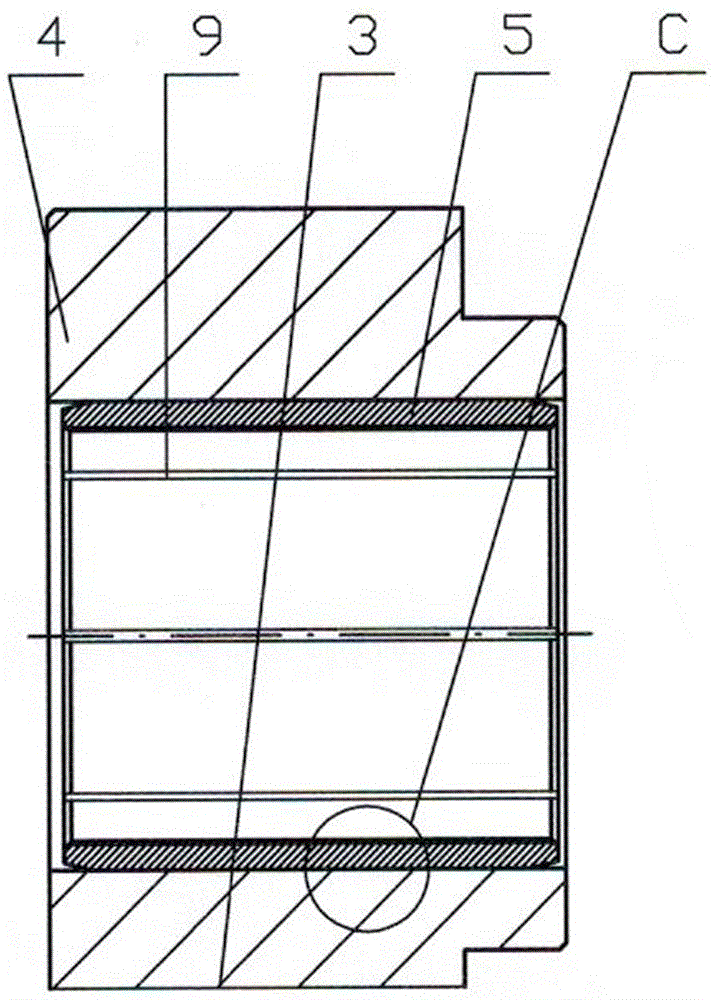

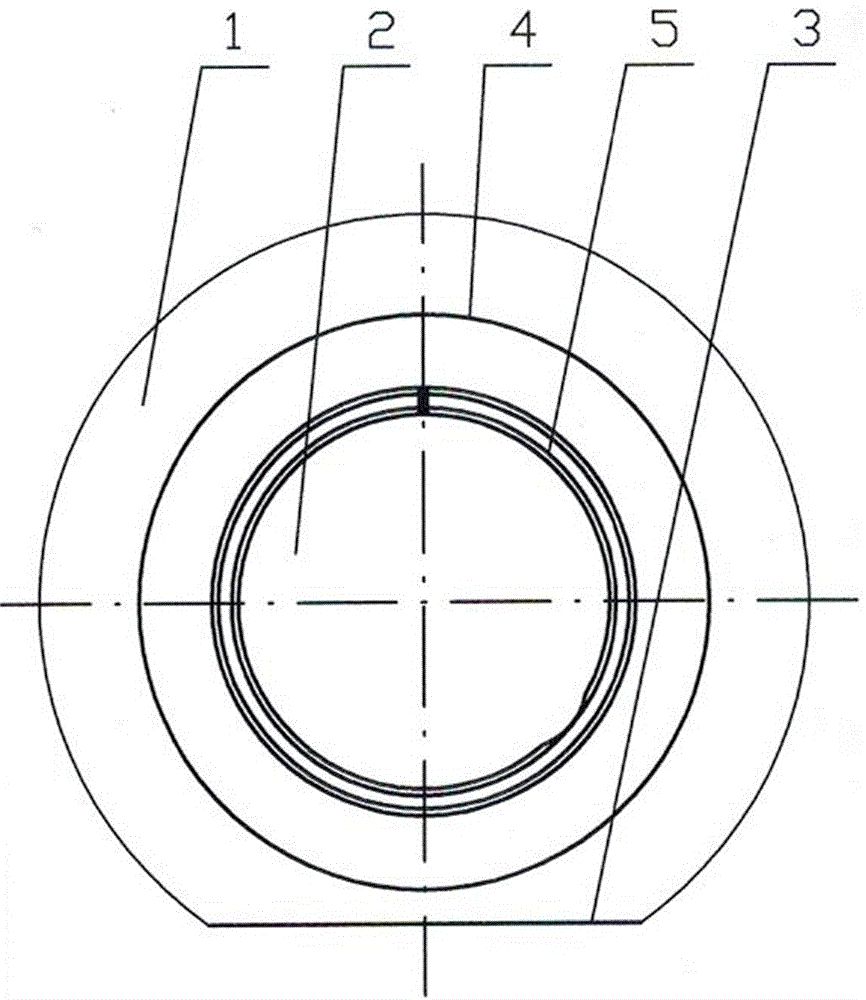

[0017] Figure 2 to Figure 4 It is a schematic diagram of the structure of the floating bushing assembly of the split gear pump. It can be seen from the figure that it includes a cylindrical bushing with a circular flange 1, and a plane 3 parallel to the shaft hole 2 is formed on the flange 1, and a floating bushing 4 is made into the floating bushing 4. A sliding bearing 5 made of a composite material roll is installed in the shaft hole 2. The sliding bearing 5 is followed by a steel sleeve 6 from the outside to the inside. The inner wall of the steel sleeve 6 is sintered with a copper alloy powder layer 7, and on the alloy copper powder layer 7 A polytetrafluoroethylene layer 8 is attached, and a spiral or 8-shaped oil groove 9 parallel to the axis is formed in the inner hole of the sliding bearing 5 . The planes 3 of the two floating bushings 4 are combined to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com