Heavy oil thermal recovery micro-displacement experimental system

A technology for displacement experiments and thermal recovery of heavy oil, which is applied in the direction of production fluid, earthwork drilling, measurement, etc., and can solve the problem of no design, no consideration of back pressure control, and holders that cannot adapt to high temperature in heavy oil thermal recovery experiments. New needs of high voltage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

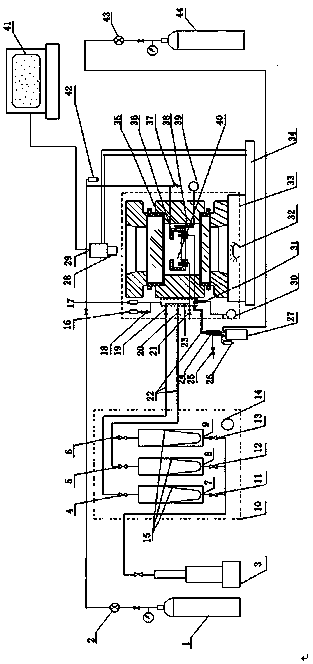

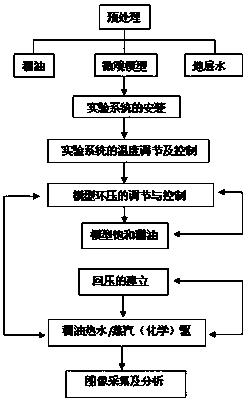

[0027] Such as figure 1 as shown, figure 1 It is a structural diagram of the micro-displacement experimental system for heavy oil thermal recovery of the present invention. The heavy oil thermal recovery micro-displacement experimental system consists of an injection system, a model system, an output system, and an image acquisition and analysis system.

[0028] Injection system, in which the injection pump provides the power source, and three high-temperature and high-pressure intermediate containers with detachable pistons in the fluorine rubber liner are placed in the incubator to provide displacement heat fluid for the experiment, and the connecting pipeline outside the incubator is wrapped with The heating insulation belt keeps the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com