Tinpot heavy oil processing and treating method

A low-quality heavy oil and treatment method technology, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, to achieve the effects of stable and uniform reaction heat release, high yield, and fast deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

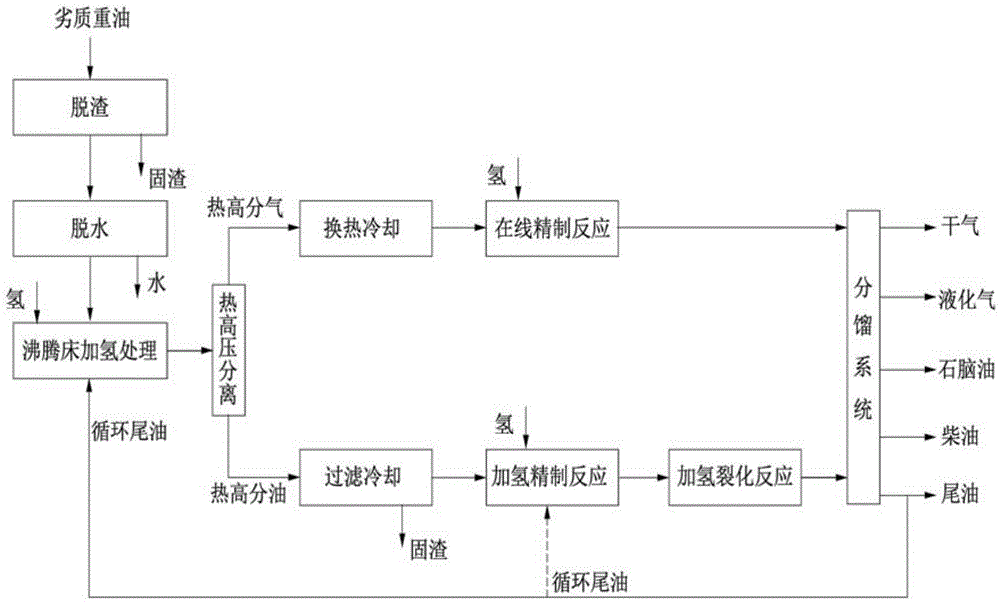

Method used

Image

Examples

Embodiment 1

[0049] (1) Medium and low-temperature coal tar from lignite in Shenmu County, whose properties are shown in Table 1, is sent into a centrifuge, centrifugally deslagging and fractionated dehydration, and the solids in the coal tar are removed until the particle diameter is less than 40um;

[0050] (2) Mix the heavy oil and hydrogen gas obtained in step (1) into the ebullated bed hydrogenation reactor for hydrogenation reaction. When the ebullated bed hydrogenation reactor is undergoing hydrogenation reaction, the catalyst is in a flowing state, and the catalyst is discharged and added online. , the active component of the catalyst is Ni, Co or Mo metal, the hardness is 15N / mm 2 Above; ebullated bed reaction temperature 388°C, reaction pressure 15.5MPa, hydrogen-oil volume ratio 500:1 and liquid hourly volume space velocity 1.0h -1 ;

[0051] (3) The reaction product obtained in step (2) is directly sent to a hot high-pressure separator, and the hot high-separation gas and hot ...

Embodiment 2

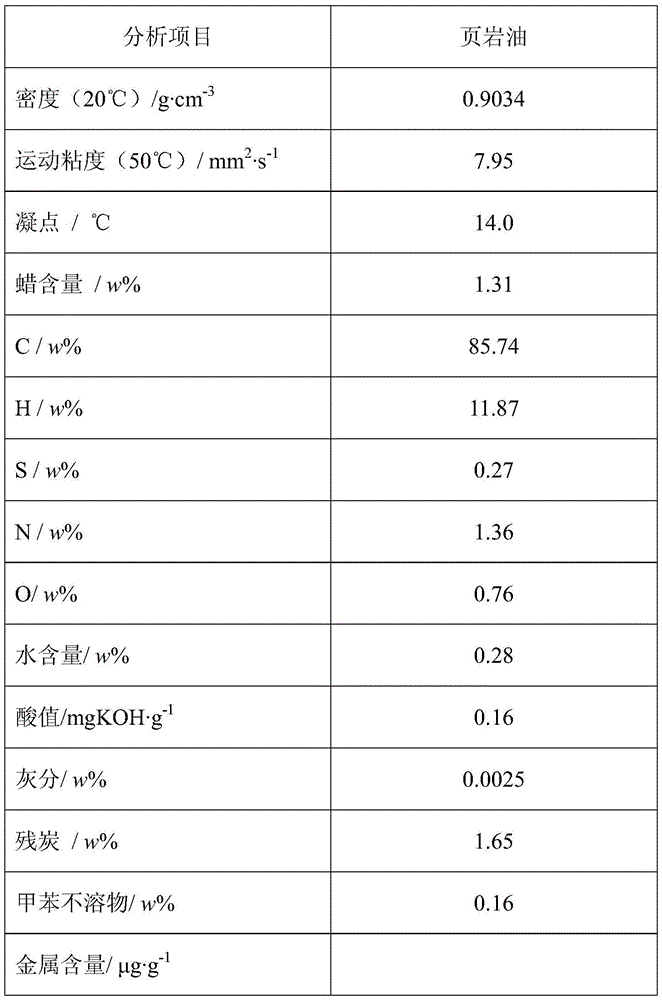

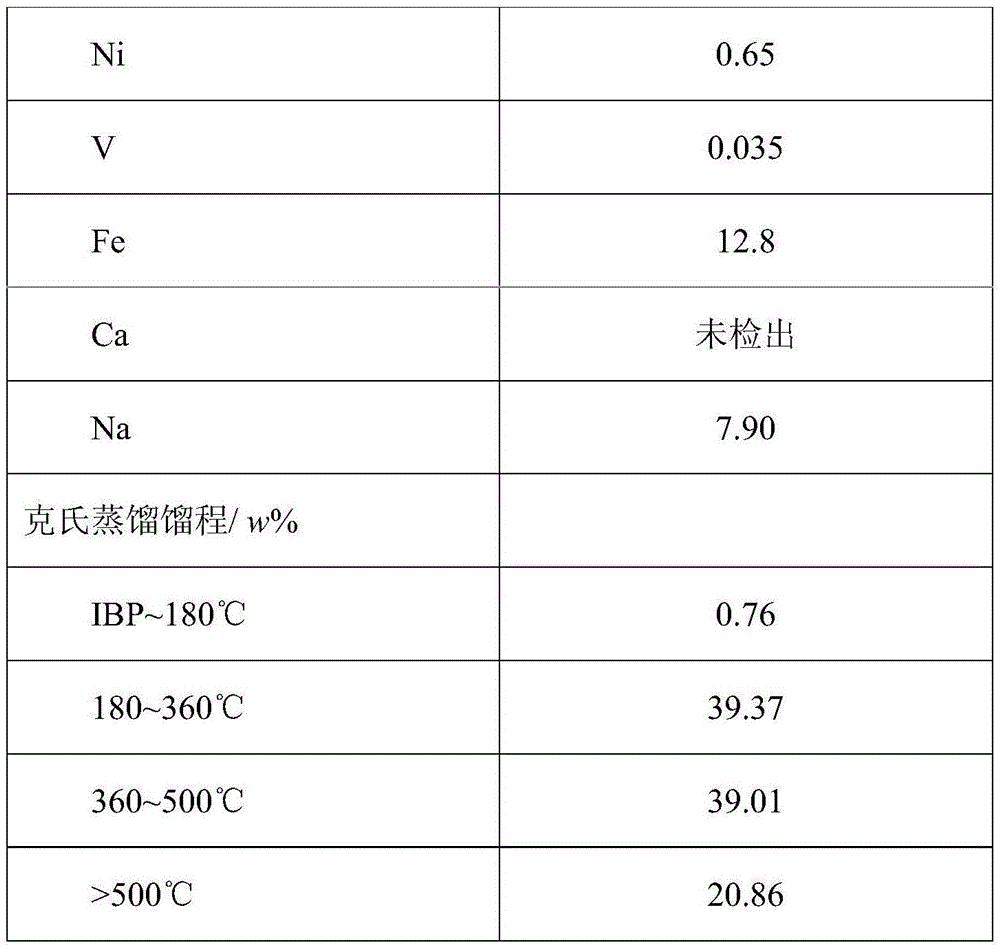

[0063] (1) The shale oil produced in Jimsar County, Xinjiang, whose properties are shown in Table 4, is sent to electric desalting to remove the salt metals in the shale oil to less than 10ppmwt; then the water is removed to the water level through the atmospheric tower Content less than 300ppmwt

[0064] (2) Mix the heavy oil and hydrogen gas obtained in step (1) into the ebullated bed hydrogenation reactor for hydrogenation reaction. When the ebullated bed hydrogenation reactor is undergoing hydrogenation reaction, the catalyst is in a flowing state, and the catalyst is discharged and added online. , the active component of the catalyst is Ni, Co or Mo metal, the hardness is 15N / mm 2 above; ebullated bed reaction temperature 400°C, reaction pressure 15.5MPa, hydrogen-oil volume ratio 700:1 and liquid hourly volume space velocity 0.8h -1 ;

[0065] (3) The reaction product obtained in step (2) is directly sent to a hot high-pressure separator, and the hot high-separation ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com