Method using centrifugal extraction to prepare gradient film modified by single epoxy terminated polysiloxane

A polysiloxane and single epoxy sealing technology is applied in the field of preparing single epoxy terminated polysiloxane modified gelatin gradient film by centrifugal extraction method, which can solve the problems affecting film structure, film performance and film application, plastic feeling strong, water resistance and poor corrosion resistance, etc., to achieve the effect of superior performance, low surface tension and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

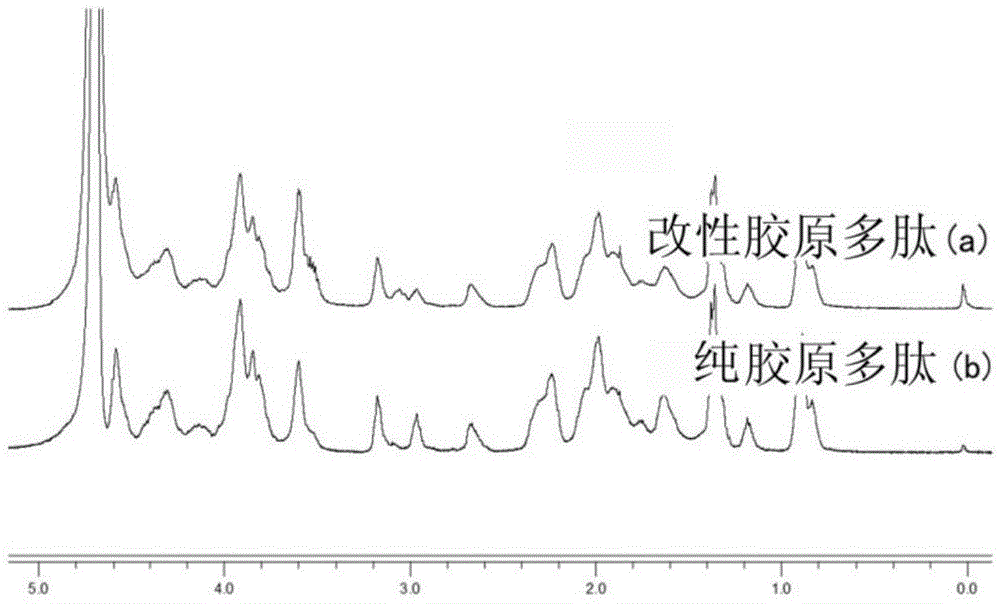

[0025] Add 0.3g of surfactant and 95g of deionized water into a three-neck reaction flask equipped with a thermometer socket, a sampling port, and a condenser socket, stir and heat to 50°C, and after the surfactant is completely dissolved, add 0.65mL of 2 mol / L sodium hydroxide, adjust the reaction pH to be 10.0, add 5g gelatin (accounting for 5% of the total solution mass), continue to stir until the gelatin is completely dissolved, and then add monoepoxy-terminated polysiloxane (Mw=500) continuously or in batches ), the consumption of single epoxy-terminated polysiloxane is 0.8 times of the primary amino molar weight in the gelatin molecule, the reaction starts, the primary amino content in the reaction system no longer changes in 24 hours, stops stirring and heating, obtains single Epoxy-terminated polysiloxane modified gelatin solution. Centrifuge the mono-epoxy-terminated polysiloxane-modified gelatin solution at low temperature at a speed of 10,000 r / min for 20 minutes, ...

Embodiment 2

[0030] The described method is consistent with Example 1, the only difference is that the rotating speed is 8000r / min, and the time is 20min.

[0031] Mix the white product and deionized water evenly at a mass ratio of 1:1, then mix evenly at a ratio of 3:1 between the mixed liquid and ethanol, measure 0.5ml of the mixed solution and add it dropwise to the polytetrafluoroethylene substrate First, freeze it with liquid nitrogen, and then dry it with a freezer to obtain a modified gelatin film. The contact angle test shows that the contact angle of the raw gelatin film is 72 o , the contact angle of the modified gelatin film increased to 95 o , indicating that the hydrophobicity of the modified gelatin film is improved; the differential calorimetry thermal scanner test shows that the Tg of the raw gelatin film is 223 ° C, and the modified gelatin film has two Tgs, 125 ° C and 225 ° C, respectively, indicating that the modification The gelatin film has a microphase separation s...

Embodiment 3

[0033] The described method is consistent with Example 1, the only difference is that the rotating speed is 5000r / min, and the time is 20min.

[0034] Mix the white product and deionized water evenly at a mass ratio of 1:1, then mix evenly at a ratio of 3:1 between the mixed liquid and ethanol, measure 0.5ml of the mixed solution and add it dropwise to the polytetrafluoroethylene substrate First, freeze it with liquid nitrogen, and then dry it with a freezer to obtain a modified gelatin film. The contact angle test shows that the contact angle of the raw gelatin film is 72 o , the contact angle of the modified gelatin film increased to 90 o , indicating that the hydrophobicity of the modified gelatin film is improved; the differential calorimetry thermal scanner test shows that the Tg of the raw gelatin film is 223 ° C, and the modified gelatin film has two Tgs, 155 ° C and 212 ° C, respectively, indicating that the modification The gelatin film has a microphase separation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com