Porous phthalonitrile resin and preparation method thereof, and application of resin

A technology of phthalonitrile resin and phthalonitrile, which is applied in the field of porous materials to achieve the effects of excellent heat resistance and mechanical properties, and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

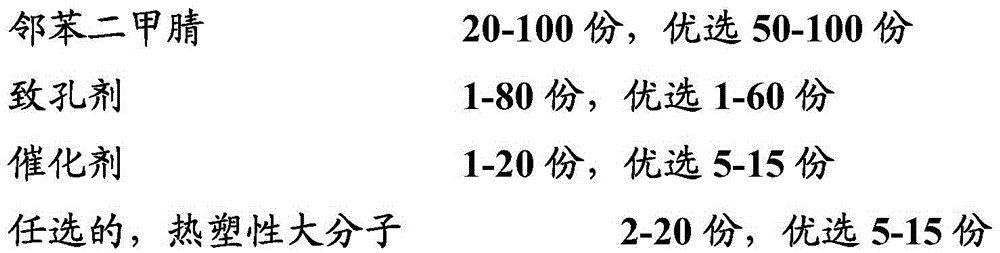

[0057] In a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 100 g of m-phenylene ether type phthalonitrile shown in formula (I), slowly heat up to 150 ° C, and add 10 g of polyarylether nitrile after the temperature stabilizes (PEEN), add 20g of polytrimethylene carbonate after PEEN is dissolved, react at a constant temperature of 150°C until the resin system is uniform and transparent, keep the temperature for 30min, cool down to 110°C, add 10g of 4,4'-diaminodiphenylmethane, stir After 10 minutes, the modified phthalonitrile resin was obtained.

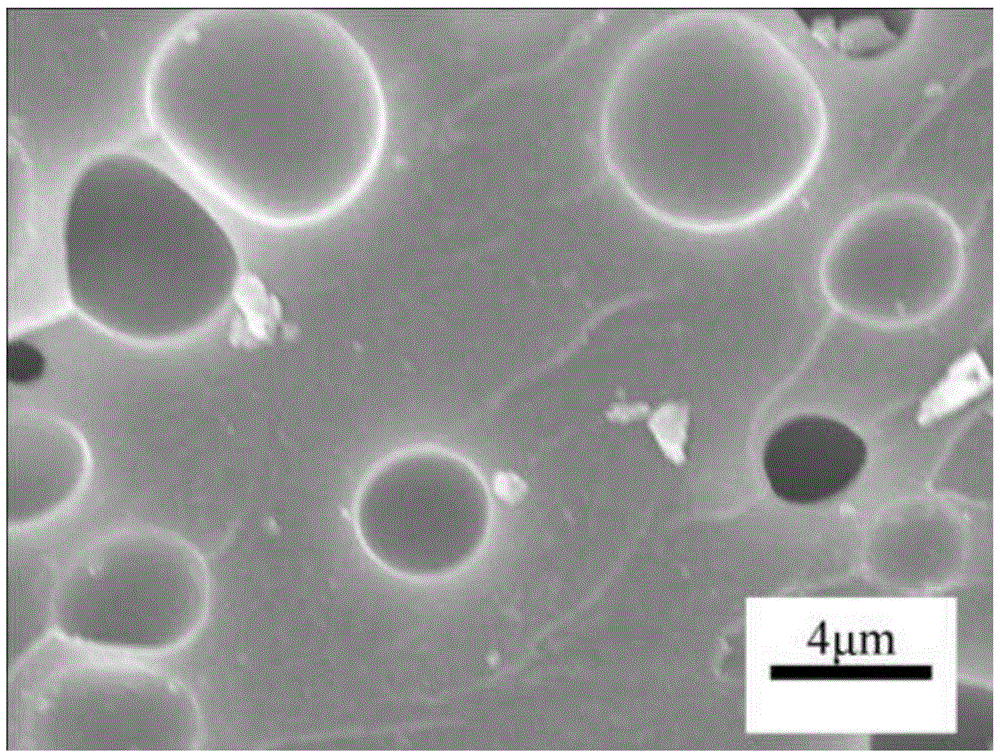

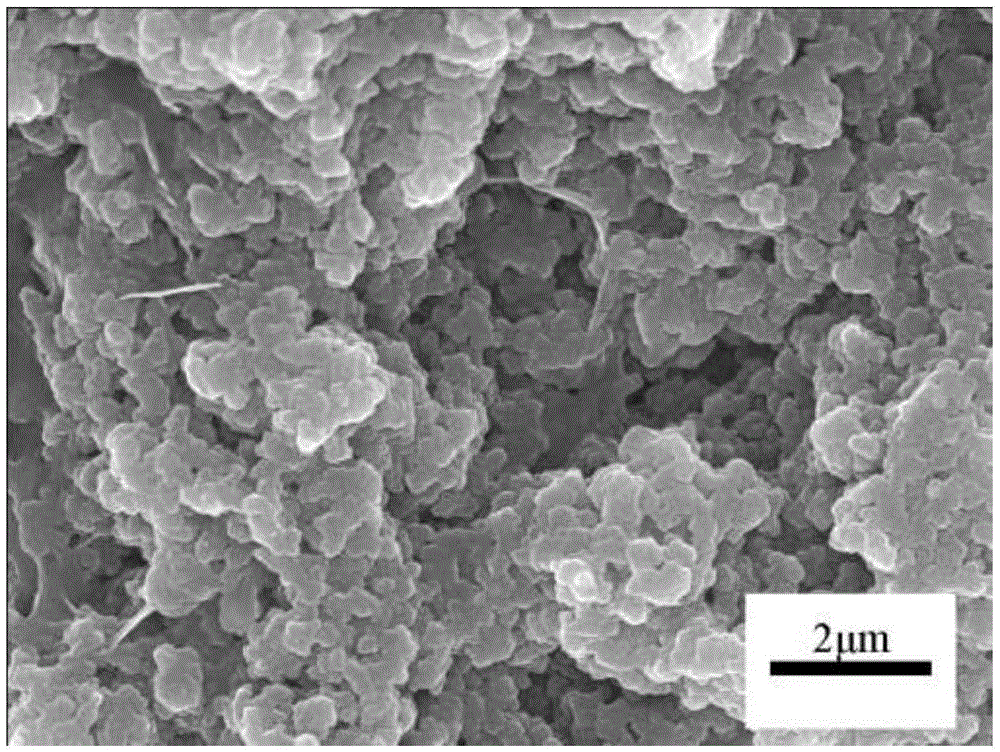

[0058] Put the modified phthalonitrile resin obtained above in a vacuum drying oven at 140° C. for 5 to 10 minutes. Until the system has no bubbles and becomes a homogeneous fluid. It is then poured into a custom-made steel mold, and then placed in an electric constant temperature drying oven to cure in stages. The curing heating process is: 170°C / 2h, 200°C / 1h, 250°C / 5h, 315°C / 2h, 350°C / 5h. A...

Embodiment 2

[0061] In a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 100 g of m-phenylene ether type phthalonitrile shown in formula (I), slowly heat up to 150 ° C, and add 10 g of polyarylether nitrile after the temperature stabilizes (PEEN), after PEEN is dissolved, add 30g of polypropylene glycol, react at a constant temperature of 150°C until the resin system is uniform and transparent, keep the temperature for 30min, cool down to 110°C, add 10g of 4,4'-diaminodiphenylmethane, and stir for 10min to obtain the modified Reactive phthalonitrile resin.

[0062] Put the modified phthalonitrile resin obtained above in a vacuum drying oven at 140° C. for 5 to 10 minutes. Until the system has no bubbles and becomes a homogeneous fluid. It is then poured into a custom-made steel mold, and then placed in an electric constant temperature drying oven to cure in stages. The curing heating process is: 170°C / 2h, 200°C / 1h, 250°C / 5h, 315°C / 2h, 350°C / 5h. A po...

Embodiment 3

[0064] In a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 100 g of phenolic phthalonitrile oligomers shown in formula (II), slowly heat up to 120 ° C, and add 10 g of polyimide after the temperature stabilizes. Amine (PI), add 40g of polymethyl methacrylate after PI is dissolved, react at a constant temperature of 120°C until the resin system is uniform and transparent, keep the reaction for 30min, cool down to 100°C, add 15g of 2,2'-bis(4-hydroxybenzene Base) propane, after stirring for 10min, the modified phthalonitrile resin was obtained.

[0065] Put the modified phthalonitrile resin obtained above in a vacuum drying oven at 140° C. for 5 to 10 minutes. Until the system has no bubbles and becomes a homogeneous fluid. It is then poured into a custom-made steel mold, and then placed in an electric constant temperature drying oven to cure in stages. The curing heating process is: 170°C / 2h, 200°C / 1h, 250°C / 5h, 315°C / 2h, 350°C / 5h. A po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com