Technique for separating and purifying succinic acid from microbial fermentation liquid

A microbial fermentation liquid, separation and purification technology, applied in the field of separation and purification of organic acids, can solve the problems of low purity, high energy consumption, low yield, etc., and achieve the effect of high purity, simple process steps, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

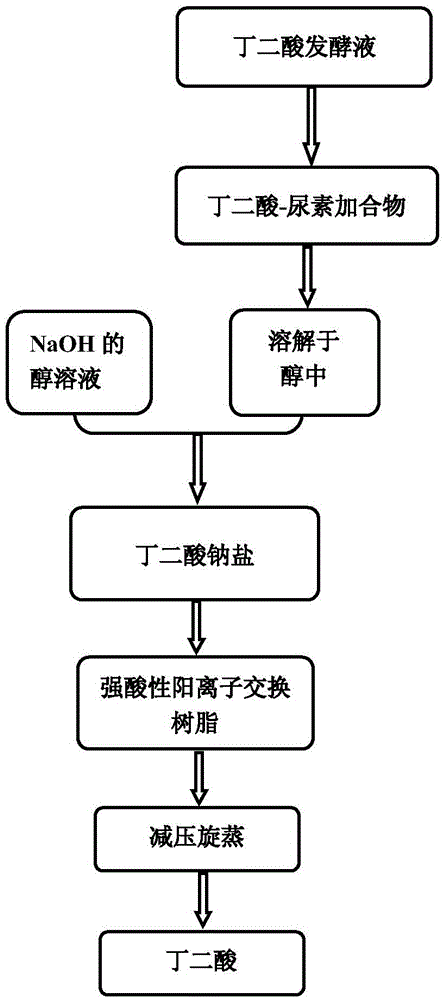

Method used

Image

Examples

Embodiment 1

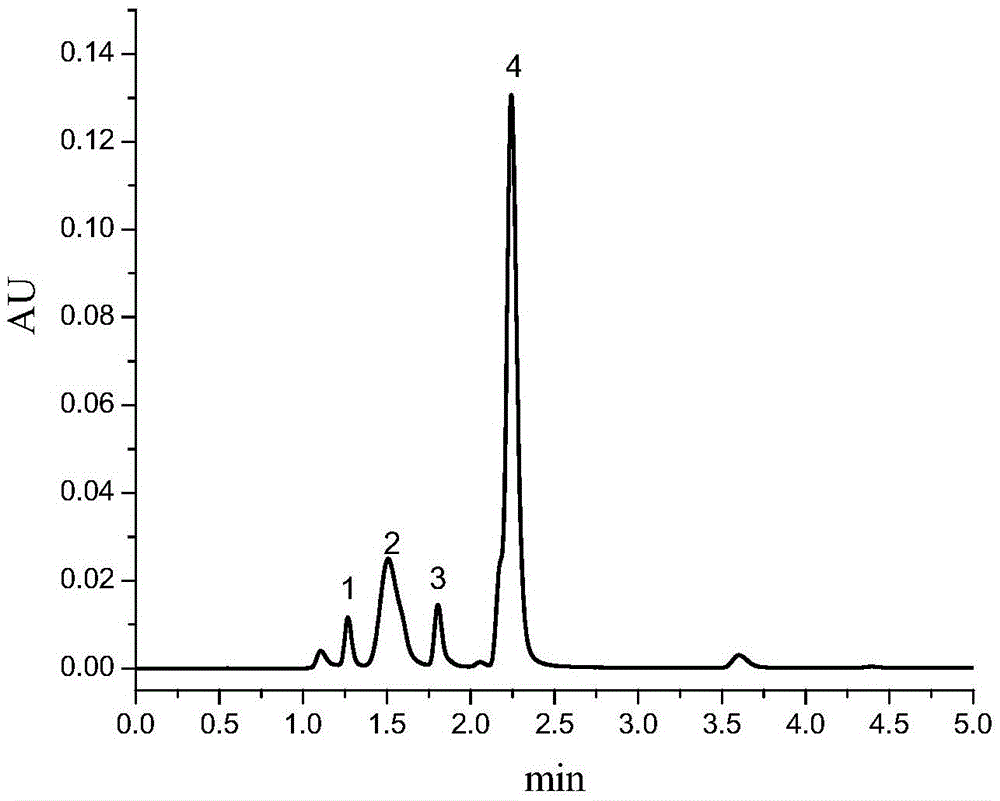

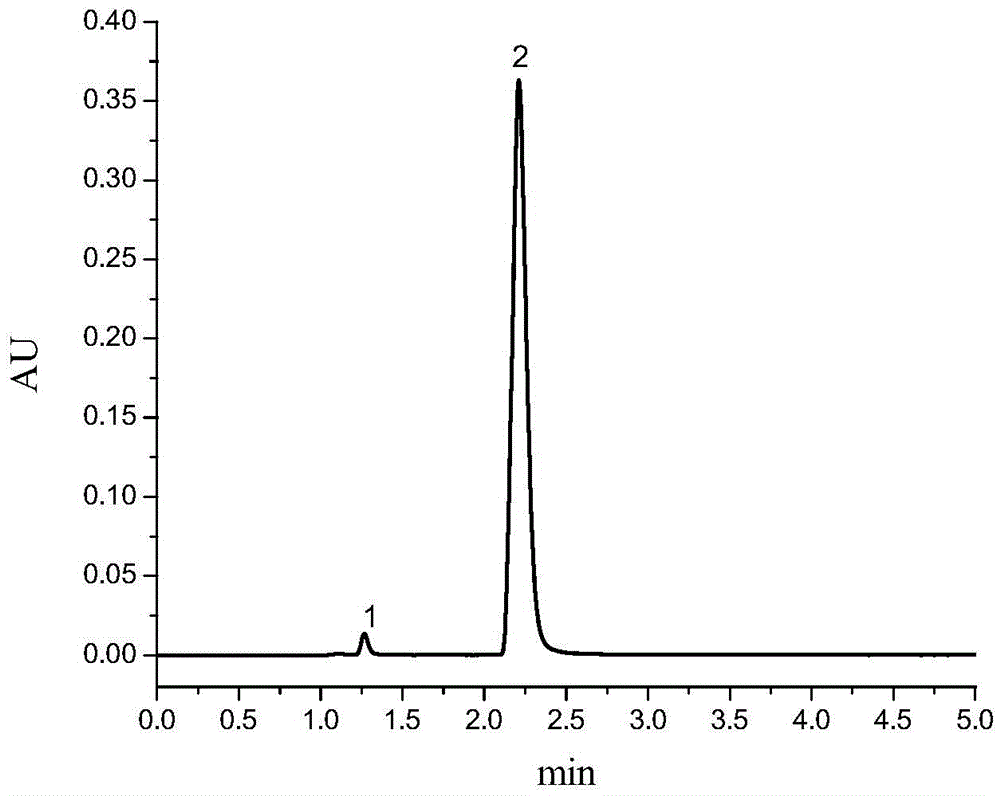

[0032] Example 1: The succinic acid-producing microorganism EscherichiacoliNZN111 fermented liquid was filtered and centrifuged to remove bacterial cells and insoluble solid particle impurities, and the supernatant fermented liquid was taken for later use. Take 10mL supernatant fermentation broth (initial succinic acid concentration is 101.77g / L) into a clean and dry test tube, add 4.0g urea to the test tube, heat in a water bath until the solid in the test tube is completely dissolved, and then place it at 4°C for 8h , filtered and dried to obtain 2.08 g of needle-like solid. Dissolve 2.08g of needle-like solid in a beaker containing 100mL of anhydrous methanol, weigh 2.1g of NaOH and dissolve it in another beaker of 100mL of anhydrous methanol, then pour the NaOH alcohol solution into the beaker containing the needle-like solid alcohol The solution was mixed in a beaker, a large amount of white solid precipitated out, filtered and dried to obtain a white solid. Dissolve the...

Embodiment 2

[0033]Example 2: The succinic acid-producing microorganism EscherichiacoliNZN111 fermented liquid was filtered and centrifuged to remove bacterial cells and insoluble solid particle impurities, and the supernatant fermented liquid was taken for later use. Take 50mL of supernatant EscherichiacoliNZN111 fermentation liquid (initial concentration of succinic acid 101.77g / L) in a clean and dry test tube, add 20.0g of urea to the test tube, sonicate until the solid in the test tube is completely dissolved, then place it at room temperature for 8h, filter Drying yielded 10.50 g of needle-like solids. Dissolve the needle-like solid in a beaker containing 400mL of absolute ethanol, weigh 10.50g NaOH and dissolve it in another beaker containing 750mL of absolute ethanol, then pour the NaOH alcohol solution into the beaker containing the needle-like solid alcohol solution Mixing in the medium, a large amount of white solid precipitated out, filtered and dried to obtain a white solid. D...

Embodiment 3

[0034] Example 3: The succinic acid-producing microorganism EscherichiacoliNZN111 fermented liquid was filtered and centrifuged to remove bacterial cells and insoluble solid particle impurities, and the supernatant fermented liquid was taken for later use. Take 100mL of the supernatant EscherichiacoliNZN111 fermentation liquid (the initial concentration of succinic acid is 101.77g / L) in a clean and dry beaker, add 40.0g of urea to the beaker, heat in a water bath until the solid in the beaker is completely dissolved, and then place it at room temperature for 12h , filtered and dried to obtain 20.29 g of needle-shaped solid. Dissolve the needle-like solid in a beaker containing 1000mL of absolute ethanol, weigh 20.30g NaOH and dissolve it in another beaker containing 1500mL of absolute ethanol, then pour the NaOH alcohol solution into the beaker containing the needle-like solid alcohol solution After mixing in a beaker, a large amount of white solid precipitated out, which was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com