Method for extracting coenzyme Q 10 from tobacco

A technology for coenzyme and tobacco leaves, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of high price, high cost, unsuitable for large-scale promotion, etc. The effect of improving capacity, improving yield and maintaining color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

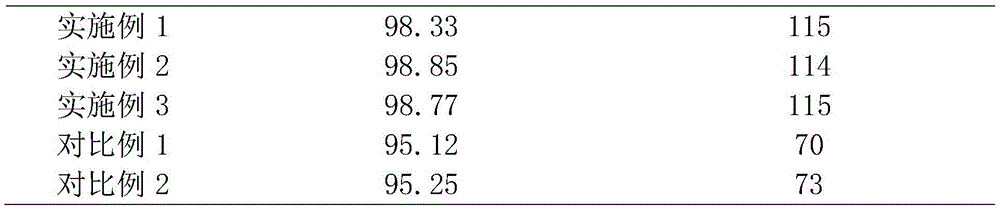

Embodiment 1

[0026] The method for extracting coenzyme Q10 from tobacco leaves specifically comprises the following steps:

[0027] 1) Pretreatment: add the same weight of pure water to the tobacco leaf extract obtained by extracting the waste tobacco leaves, and process it through high-pressure micro-jet ultrafine pulverization, and use a high-speed shear emulsifier for 3 minutes at a speed of 12000r / min, and then use The high-pressure micro-jet ultrafine pulverization equipment is used for processing at 25°C, the processing pressure is 80MPa, and the processing times are 3 times to obtain a paste-like slurry, and then use NaOH ethanol solution and petroleum ether system to dynamically saponify the bound solanesol, crystallize and filter , to obtain an extract containing solanesol;

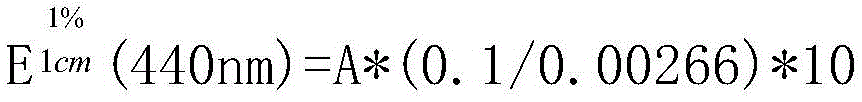

[0028] 2) Molecular distillation: the extract containing solanesol obtained in step 1) was removed by molecular distillation with a vacuum degree of 0.01Pa, a distillation temperature of 190°C, a scraper spee...

Embodiment 2

[0033] The method for extracting coenzyme Q10 from tobacco leaves specifically comprises the following steps:

[0034]1) Pretreatment: add the same weight of pure water to the tobacco leaf extract obtained by extracting the waste tobacco leaves, and process it through high-pressure micro-jet ultrafine pulverization, and process it with a high-speed shear emulsifier for 5 minutes at a speed of 8000r / min, and then use The high-pressure micro-jet ultrafine pulverization equipment is used for treatment at 25°C, the treatment pressure is 120MPa, and the treatment times are 2 times to obtain a paste-like slurry, and then use NaOH ethanol solution and petroleum ether system to dynamically saponify the bound solanesol, crystallize and filter , to obtain an extract containing solanesol;

[0035] 2) Molecular distillation: the extract containing solanesol obtained in step 1) was removed by molecular distillation with a vacuum degree of 0.01Pa, a distillation temperature of 190°C, a scra...

Embodiment 3

[0040] The method for extracting coenzyme Q10 from tobacco leaves specifically comprises the following steps:

[0041] 1) Pre-treatment: add the same weight of pure water to the tobacco leaf extract obtained by extracting the waste tobacco leaves, and process it through high-pressure micro-jet ultrafine pulverization, and use a high-speed shear emulsifier for 4 minutes at a speed of 10000r / min, and then use The high-pressure micro-jet ultrafine pulverization equipment is used for processing at 25°C, the processing pressure is 100MPa, and the processing times are 3 times to obtain a paste-like slurry, and then use NaOH ethanol solution and petroleum ether system to dynamically saponify the bound solanesol, crystallize and filter , to obtain an extract containing solanesol;

[0042] 2) Molecular distillation: the extract containing solanesol obtained in step 1) was removed by molecular distillation with a vacuum degree of 0.01Pa, a distillation temperature of 190°C, a scraper sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com