Refining agent for refining primary brine in chlorine alkali industry and application of refining agent

A technology of brine refining and chlor-alkali industry, applied in the field of new refined preparations, can solve the problems of insufficient quality of resin tower brine, achieve the effects of reducing production costs, prolonging regeneration time, and reducing operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 uses the refined preparation of the present invention to prepare primary brine

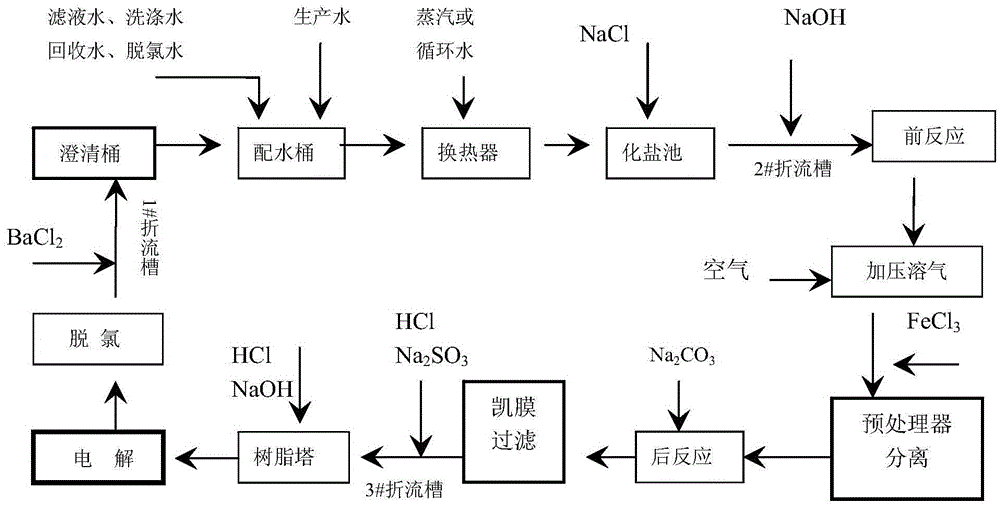

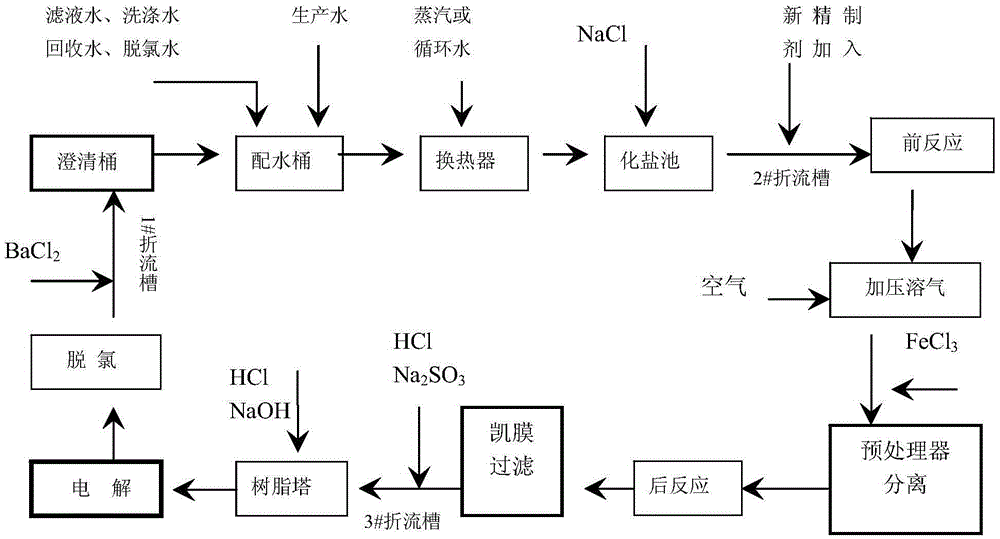

[0020] The outlet water flow rate of the salt tank is 21.5m per hour 3 , the total amount of calcium and magnesium ions is 74ppm, add 54L sodium phosphate solution containing phosphate radical 40.18g / l in 2# baffle tank per hour, after sodium phosphate fully reacts, measure the salt water phosphate excess value is 0.13g / l, go through figure 1 In the process shown, primary brine is obtained after filtration through a Kai membrane. It is determined that the total amount of calcium and magnesium in the obtained primary brine is 0.0879ppm after Kaymembrane filtration, which can be used in the next resin tower treatment process

Embodiment 2

[0021] Embodiment 2 uses the refined preparation of the present invention to prepare primary brine

[0022] The salt flow rate is 43m per hour 3 , the total amount of calcium and magnesium ions is 78ppm. Add 110L sodium phosphate solution containing phosphate radical 39.75g / l in 2# baffle tank per hour, after sodium phosphate fully reacts, measure the excess value of saltwater phosphate radical to be 0.11g / l, after figure 1 In the process shown, primary brine is obtained after filtration through a Kai membrane. After determination, the total amount of calcium and magnesium in the resulting primary brine is 0.0792ppm. Can be used in the next resin tower treatment process

[0023] Comparative example Use the original "two-alkali" refining preparation to prepare primary brine

[0024] The salt flow rate is 43m per hour 3 , the total amount of calcium and magnesium ions is 72ppm. Add 30% sodium hydroxide to the 2# baffle tank per hour, the addition amount is 5l / h, the excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com