Composite material for airborne radome and preparation method thereof

A composite material and radome technology, applied in the field of aerospace materials, to reduce weight, strengthen the structure, and improve the overall bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

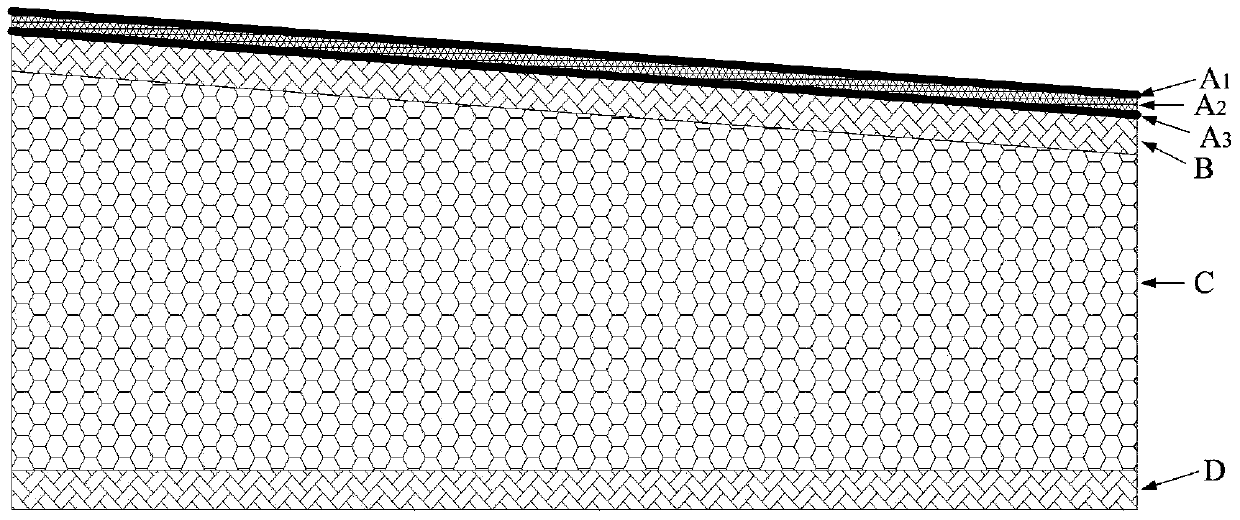

[0048] a kind of like figure 1 The composite materials for airborne radomes shown are mainly used to prepare radomes working in Ka and Ku bands. Its structure is: a surface coating A, an outer skin layer B, a sandwich layer C, and an inner skin layer D are sequentially arranged from outside to inside, wherein the sandwich layer C is arranged between the outer skin layer B and the inner skin layer D, and the surface coating Layer A is applied to the surface of outer skin layer B.

[0049] Wherein the surface coating comprises primer layer A3, anti-rain erosion paint layer A2 and antistatic paint layer A1, rain erosion resistant paint layer A2 is arranged in the middle of primer layer A3 and antistatic paint layer A1, and primer layer A3 is coated on The surface of the outer skin layer B. The thickness of the primer layer is 0.03mm; the thickness of the anti-rain erosion layer is 0.15mm; the thickness of the antistatic layer is 0.04mm.

[0050] The outer skin layer uses quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com