Special device for precision bonding of ultra-thin ring slices and its bonding process

A special device and ring-sheet technology, applied in the field of ultra-thin ring-sheet precision bonding special device and its bonding process, can solve the problems of easy deformation, uneven thickness of the adhesive layer, inconsistent density of the adhesive layer, etc., to avoid deformation , Guarantee the end-jumping accuracy and enhance the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

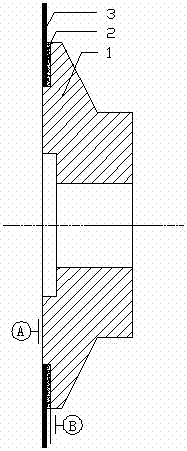

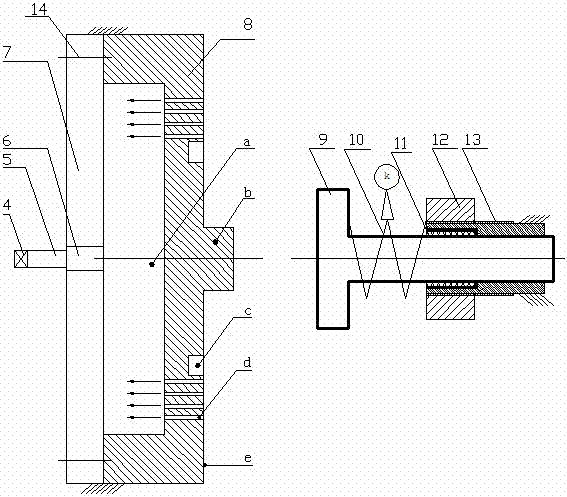

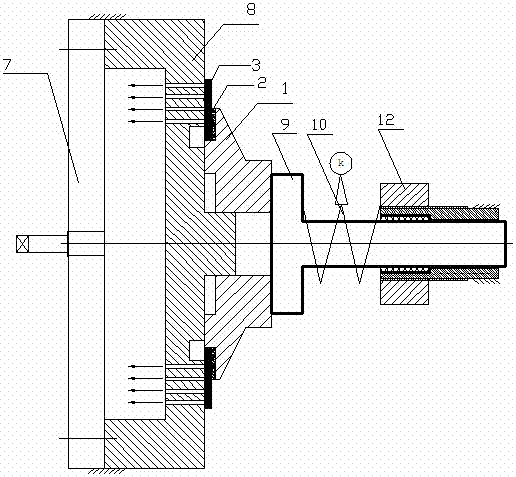

[0024] Such as figure 2 As shown, the special device for precision bonding of ultra-thin ring pieces includes a vacuum suction cup and a top tightening mechanism. The vacuum suction cup is composed of a base 7, an end cover 8, a rotary joint 6, an air pipe 5 and a valve 4: the end cover 8 is covered on the base 7, and a cavity is formed between the base 7 and the end cover 8, a threaded through hole is provided at the center of the base 7, one end of the rotary joint 6 is threaded with the threaded through hole, the other end is connected to the air pipe 5, and the other end of the air pipe 5 Connect the valve 4; the jacking mechanism is composed of the ejector rod 9, the pressure gauge spring 10, the linear bearing 11, the hollow screw rod 13 and the driving screw sleeve 12: the ejector rod 9 is in the shape of ┣, and the right end of the ejector rod 9 is in order from inside to outside A linear bearing 11, a hollow screw rod 13 and a drive screw sleeve 12 are sleeved, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com