Vertical shaft impact type crusher

A vertical shaft impact and crusher technology, applied in the field of mining machinery, can solve the problems of increasing economic investment, being susceptible to wear and tearing, and the crushing effect is not good, and achieves the effect of good crushing effect and enhanced crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose and features of the present invention more obvious and easy to understand, the following will further describe the specific embodiments of the present invention in conjunction with the accompanying drawings. However, the present invention can be realized in different forms, and should not be considered as being limited to the described embodiments .

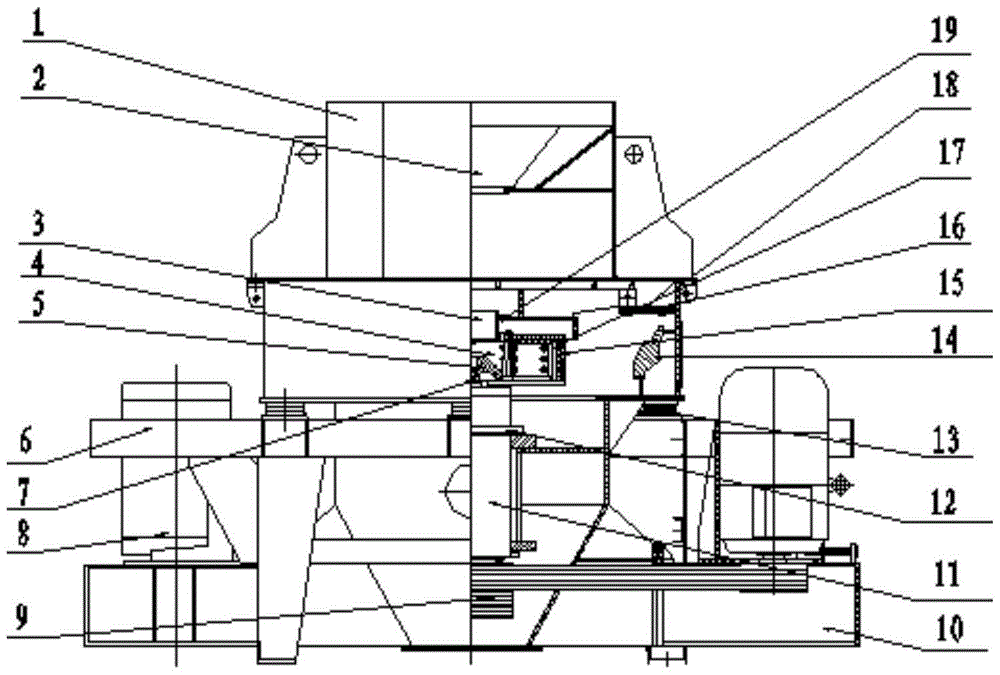

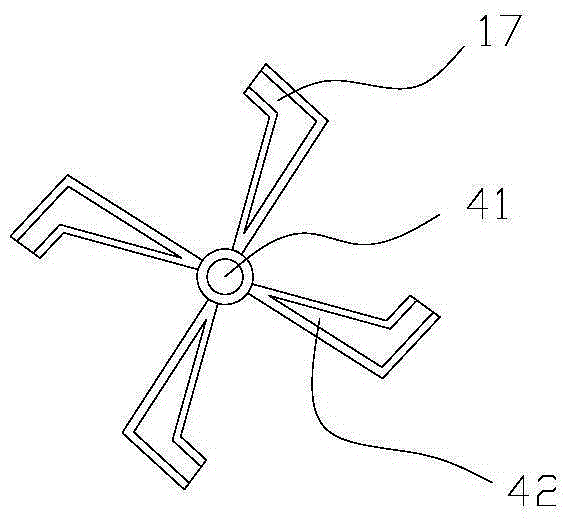

[0024] Such as figure 1 As shown, it is a vertical shaft impact crusher of the present invention, which includes a housing 1, a feed port 2, a feed pipe 3, an impeller body 4, a distributing device 5, a base 6, a main shaft assembly 7, a motor 8, Pulley 9, motor frame 10, bearing 11, sealing cover 12, elastic block 13, peripheral guard plate 14, counter-attack block 15, liner plate 16, material throwing head 17, body 18 and runner plate 19. Such as figure 1 As shown, a motor frame 10 is fixedly installed on the base 6, and a motor 8 is arranged on the motor frame 10, wherein, in the figure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com