Corner self-servo passive and supple hydraulic robot joint

A hydraulic robot and self-servo technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as poor assembly of the valve body, difficult machining accuracy, and easy displacement of the valve body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

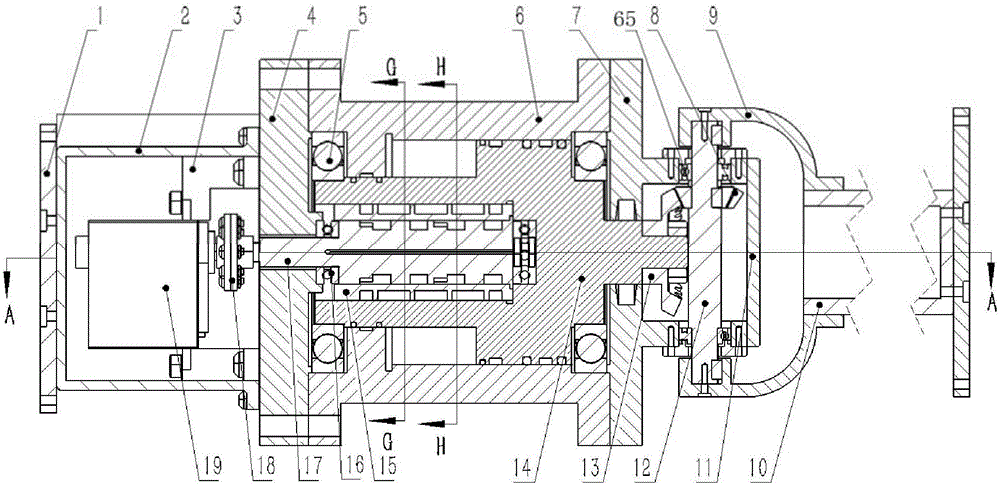

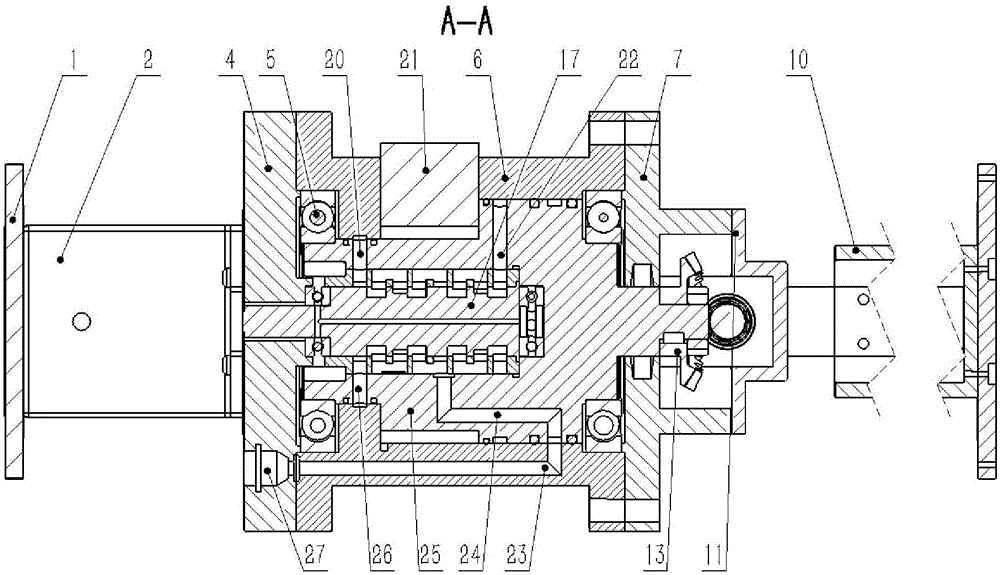

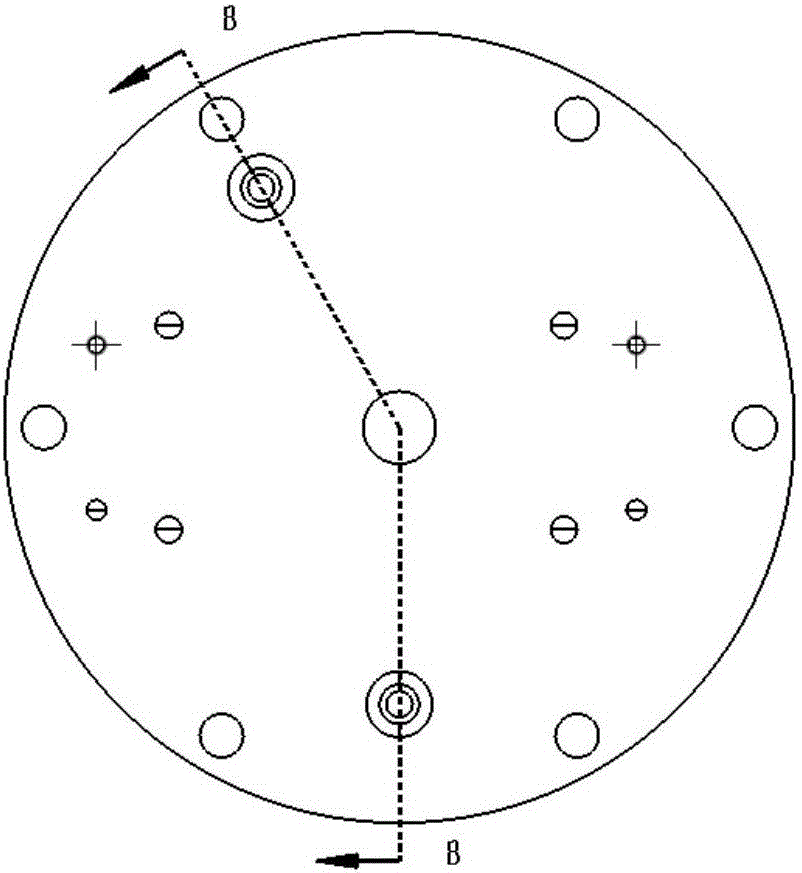

[0078] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-26 As shown, a corner self-servo passive compliant hydraulic robot joint includes a steering gear 19, a steering gear cover 2, a steering gear disc 18, a steering gear seat 3, a cylinder body 6, a valve sleeve 15, a valve core 17, a valve body 14, Fixed block 21, blade 25, driving bevel gear 13, driven shaft 12, driven bevel gear 8, gear cover 11, connecting rod 9, driven arm 10 and connection plate 1;

[0079] Such as figure 1 and figure 2 As shown, the valve body 14 is concentrically installed in the cylindrical cavity 32 of the cylinder body, and the left and right ends of the valve body 14 are concentrically equipped with two deep groove ball bearings 5, and the left end deep groove ball bearing is fixed on the left bearing of the cylinder body. In the groove 29, the right end deep groove ball bearing is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com