Novel hemostatic material and preparation method thereof

A hemostatic material and a new type of technology, applied in the field of medical biomaterials, can solve the problems of limited kaolin particles, limited scope of use, and difficulty in subsequent processing, and achieve the effects of no sensitization, low cost, and no skin irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

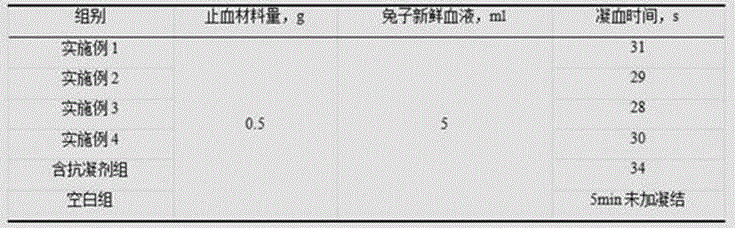

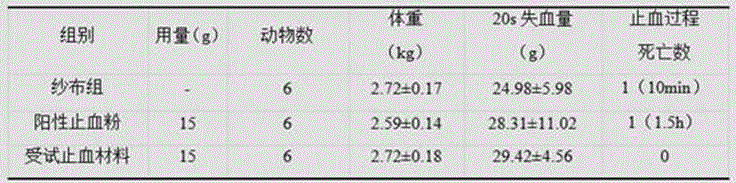

Examples

preparation example Construction

[0036] The technology disclosed in the present invention relates to a preparation method of a novel hemostatic material, comprising the following steps:

[0037] (1) After drying a certain amount of washed kaolin raw ore at 105°C, crush it to less than 2mm, make a 4g / L slurry with water, and add 0.6% raw ore mass (NaPO 3 ) 6 , stir and disperse for 45 minutes, naturally age for 6 hours, extract the supernatant, control the concentrate yield to 40-45%, place the concentrate rack further to separate the excess water, and dry the material to obtain the concentrate. Add the water-washed kaolin concentrate to the hydrochloric acid solution with a mass ratio of 5-30%, raise the temperature to 55-105°C under stirring, and pickle and refine for 4-24h. After solid-liquid separation, the reaction product is washed to pH 5.5-7.5, dried and pulverized. Transfer the pulverized product to a roasting furnace and roast at a temperature of 450-850°C for 1.5-4.5 hours to obtain activated kaol...

Embodiment 1

[0045] (1) Weigh 2.5kg of kaolin (provided by Maoming Kaolin Technology Co., Ltd.), dry it at 105°C, crush it to 2mm, make a 4g / L slurry with water, add 15g of (NaPO 3 ) 6 , stir and disperse for 45 minutes, naturally age for 6 hours, extract the supernatant, control the concentrate yield to 45%, place the concentrate rack further to separate excess water, and dry the material. Then slowly add it to a hydrochloric acid solution with a concentration of 5% by mass, and pickle with stirring at a temperature of 55°C for 24 hours. After solid-liquid separation, the product is washed with pure water until the pH of the washing liquid is 7.5, dried and crushed. Transfer the pickled kaolin to a roasting furnace at 450°C for 4.5 hours and set aside;

[0046] (2) Weigh 10kg of sodium acrylate solution with a mass percent concentration of 18%, adjust the pH to 4.5-7.5 with hydrochloric acid solution, add N,N-methylenebisacrylamide at 0.001% of the molar number of sodium acrylate, and s...

Embodiment 2

[0049] (1) Weigh 10kg of sodium acrylate solution with a mass percentage concentration of 18%, adjust the pH to 4.5-7.5 with hydrochloric acid solution, add 2% glycerol to the molar number of sodium acrylate, stir to fully dissolve and evenly. Add ammonium bicarbonate according to 5% of the mass of the sodium acrylate solution, and add kaolin prepared in step (1) of Example 1 at 6:1, and stir until dispersed evenly to form a slurry solution. Potassium persulfate with 5 mol% sodium acrylate was added, stirred evenly and then transferred to a polymerization kettle to initiate polymerization. After the reaction is completed, the polymer is coarsely crushed and dried in a dry environment at 125-185°C, and the first-grade product is obtained after granulation;

[0050] (2) The calcium chloride solution with a concentration of 1% by mass is evenly sprayed on the surface of the first-grade product according to the proportion of 0.8% of the first-grade product quality. After completi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com