Hybrid excitation flux switching motor

A magnetic flux switching motor and mixed excitation technology, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of reducing torque density, poor magnetic adjustment effect, reducing power density and torque density, etc. Achieve the effects of reducing rotor size, increasing electromagnetic load, and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

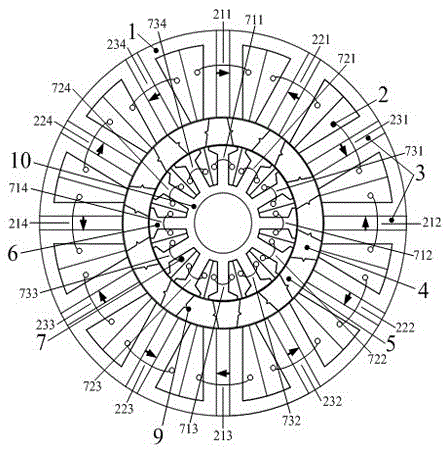

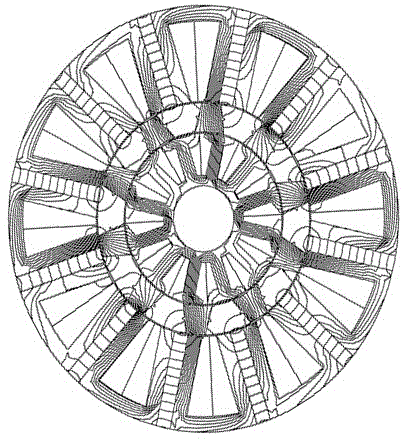

[0016] see figure 1 , The motor structure of the present invention includes an outer stator, a rotor and an inner stator. The inner stator is coaxially covered with the rotor, and the rotor is coaxially covered with the outer stator. There are radial air gaps between the rotor, the inner stator and the outer stator.

[0017] The outer stator is composed of an outer stator core, a permanent magnet 3 and a three-phase armature winding 2, and the permanent magnet 3 is made of NdFeB or ferrite or other permanent magnet materials. Wherein, the outer stator core is composed of 12n U-shaped permeable magnetic cores 1, n is an integer, and n≥1. The U-shaped magnetically permeable core 1 is laminated with silicon steel sheets. The U-shaped notch of the U-shaped magnetically permeable core 1 faces the axis of the outer stator, and the two side walls of the U-shape of the U-shaped magnetically permeable core 1 are outer stator teeth. There are 12n U-shaped permeable magnetic cores 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com