Nickel-cobalt-aluminium oxide precursor, nickel-cobalt-aluminium oxide and preparation method therefor

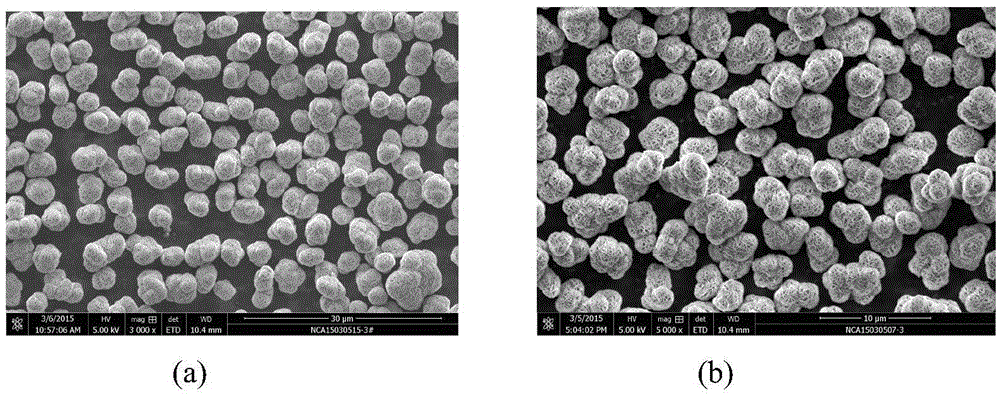

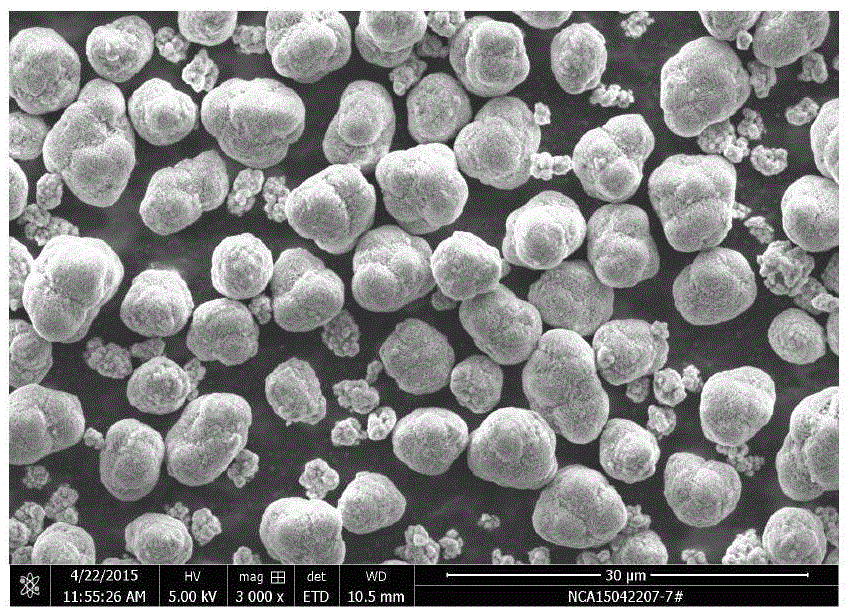

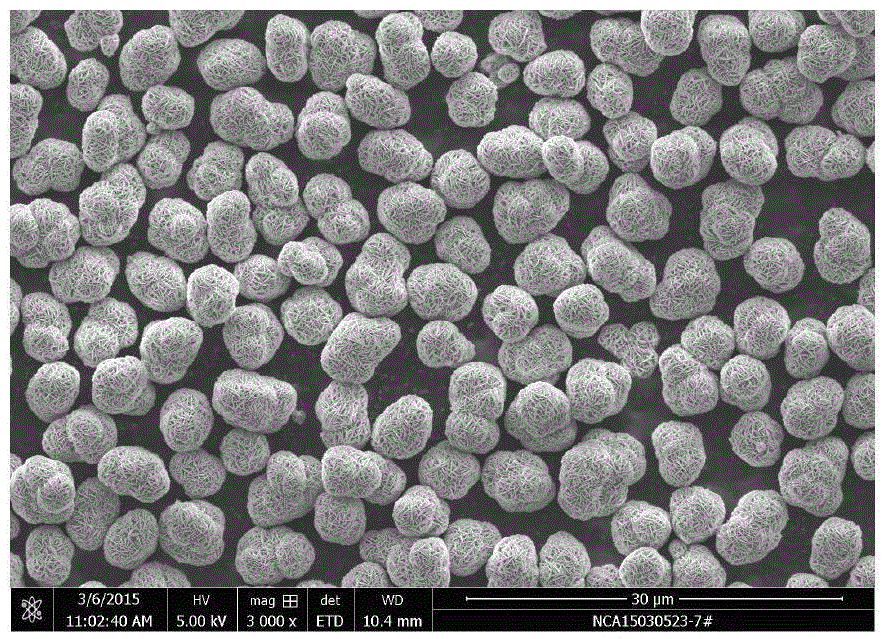

A nickel-cobalt hydroxide and oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor sphericity and uneven element distribution of nickel-cobalt-aluminum materials, and achieve good consistency and volume shrinkage Small, good spherical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] Please refer to figure 1 , figure 1 It is a flow chart of the preparation method of nickel-cobalt-aluminum oxide precursor in the present invention, comprising the following steps:

[0069] S01, prepare the mixed salt solution of nickel salt and cobalt salt, the mol ratio of nickel and cobalt ions in the mixed salt solution is (1.5~12):1, get complexing agent, precipitating agent, described complexing agent, The precipitant and the mixed salt solution are added to the reactor under stirring conditions to carry out the co-precipitation reaction. During the reaction, the reaction temperature is controlled in the range of 45-70 °C, and the pH value is in the range of 9.5-11.5. Finally, solid-liquid separation is performed on the reacted material to obtain a solid product, and the solid product is washed and dried to obtain nickel-cobalt hydroxide;

[0070] S02. Take the organoaluminum source for heating and melting, mix the melted organoaluminum source with the above-m...

Embodiment 1

[0072] A preparation method of nickel cobalt aluminum oxide, comprising the following steps:

[0073] (1) prepare the mixed salt solution of nickel nitrate and cobalt nitrate, the mol ratio of nickel and cobalt ions in the mixed salt solution is 9:0.085; add reaction bottom liquid in co-precipitation reactor, reaction bottom liquid is water, complex Mixture—a mixed system of ammonia water and sodium hydroxide. At the beginning of the reaction, the concentration of ammonia water in the reaction bottom liquid is 4g / L. NaOH is used to adjust the pH value of the reaction bottom liquid to 9.5, the temperature is 45°C, and the rotation speed is 150r / min , the prepared nickel-cobalt mixed salt solution and the concentration of 5 ~ 6g / L of ammonia, the concentration of 32% NaOH solution are added to the reaction kettle in parallel to carry out the coprecipitation reaction, wherein the addition speed of the nickel-cobalt mixed salt is 100L / h, the addition rate of NaOH is 28L / h, the add...

Embodiment 2

[0082] A preparation method of nickel cobalt aluminum oxide, comprising the following steps:

[0083] (1) prepare the mixed salt solution of nickel sulfate, cobalt sulfate, the mol ratio of nickel, cobalt ion is 8:1 in the described mixed salt solution; Add reaction bottom liquid in coprecipitation reactor, reaction bottom liquid is water, complex Mixture—a mixed system of ammonia water and sodium hydroxide. At the beginning of the reaction, the concentration of ammonia water in the reaction bottom liquid is 5g / L. NaOH is used to adjust the pH value of the reaction bottom liquid to 9.7, the temperature is 50°C, and the rotation speed is 130r / min , using as figure 2 Stir with the stirring paddle shown; add the prepared nickel-cobalt mixed salt solution, ammonia water with a concentration of 5g / L, and NaOH solution with a concentration of 30% into the reactor to carry out coprecipitation reaction, wherein, nickel-cobalt mixed The addition rate of salt is 140L / h, the addition r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com