Positive electrode material precursor of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable structure of positive electrode materials and impact on safety performance, achieve good cycle stability, reduce mixed discharge, and prevent mixed discharge. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

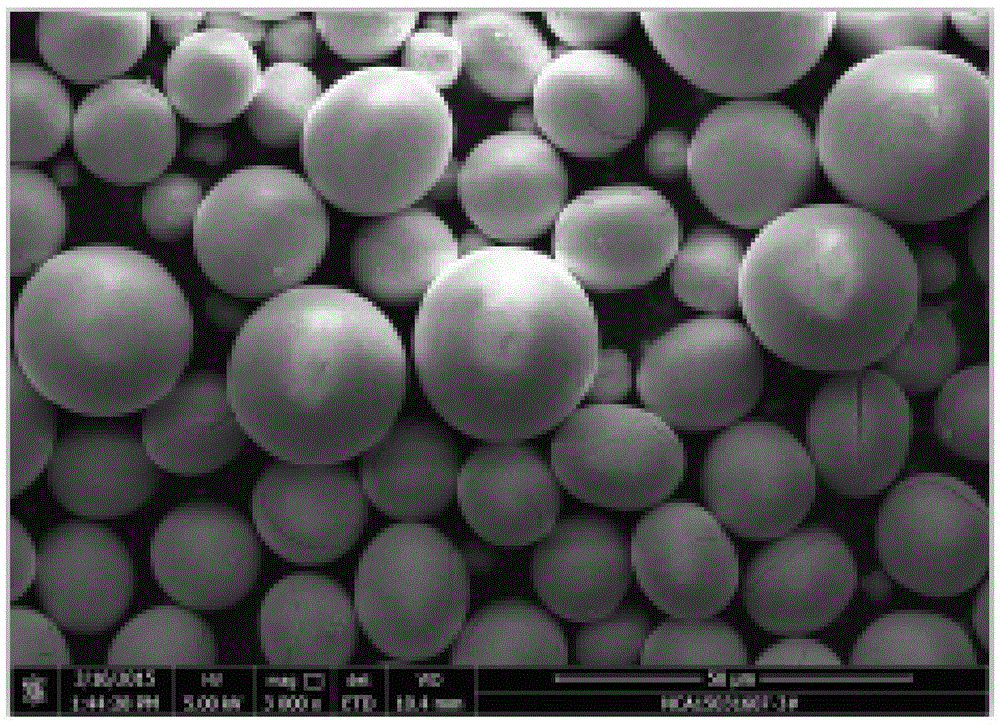

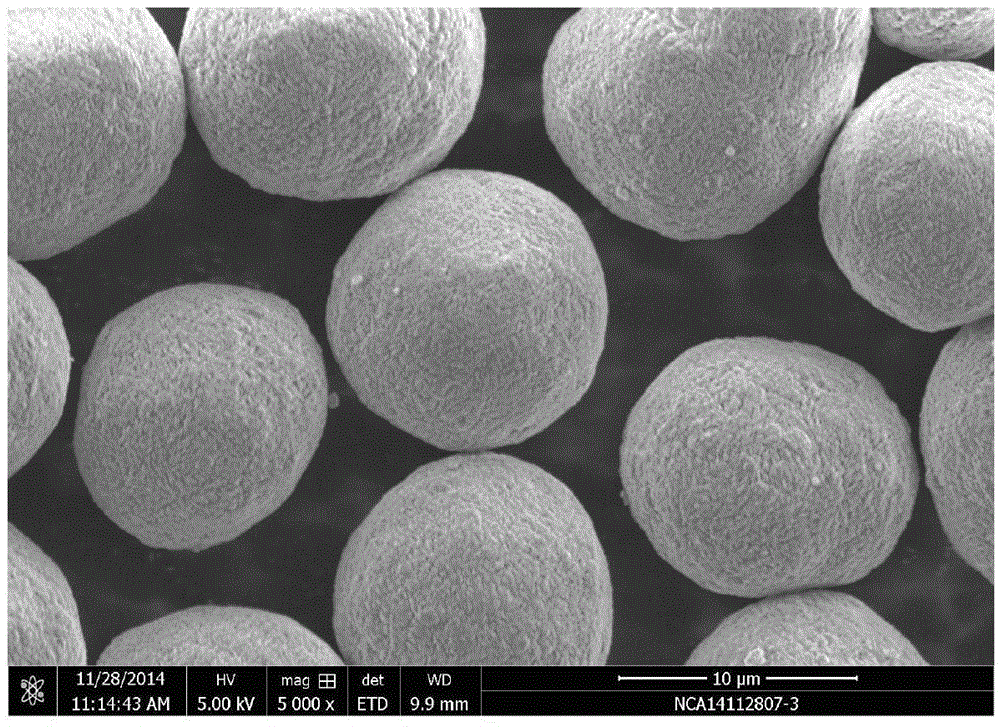

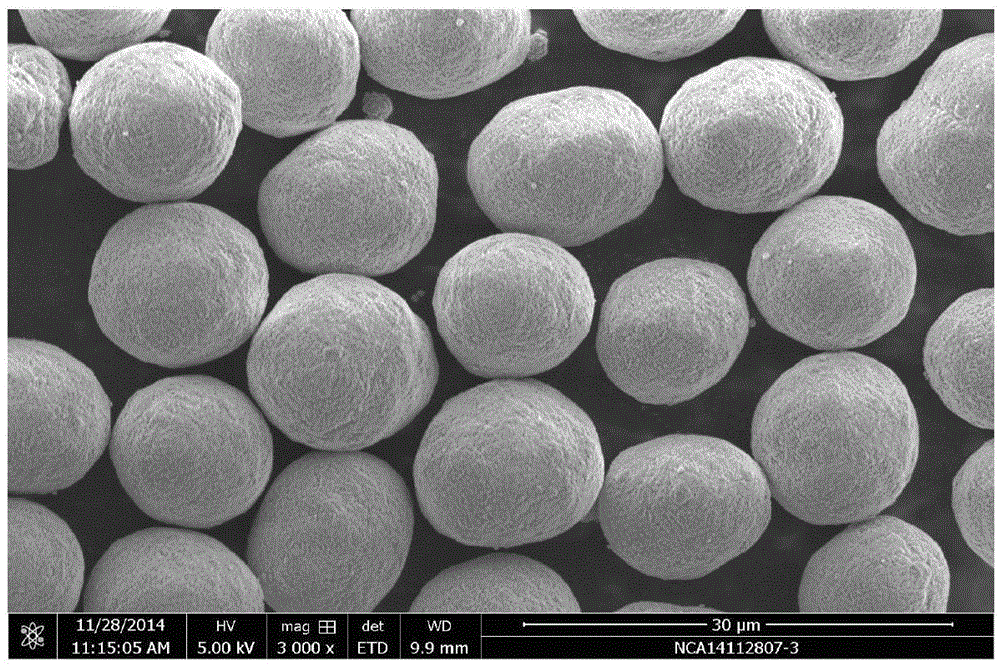

[0059] A preparation method of a lithium ion battery cathode material precursor, comprising the following steps:

[0060] (1) Preparation of the inner core: the molar concentration ratio of nickel sulfate and cobalt sulfate is 9:1 to prepare nickel-cobalt mixed salt solution, wherein the total concentration of nickel and cobalt ions is 1.5mol / L; prepare 18wt% ammonia water, 6mol / L L of sodium hydroxide solution, with ammonia as a complexing agent, NaOH as a precipitating agent. Add the nickel-cobalt mixed salt solution to the reactor at a rate of 120L / h with a metering pump, and add ammonia water to the reactor at a rate of 15L / h for coprecipitation reaction. The reaction temperature is 65°C, the pH value is controlled at 11.0, and the reaction is carried out for 16 hours. Inner core, namely [Ni(OH) 2 ] 0.9 ·[Co(OH) 2 ] 0.1 ;

[0061] (2) Formation of core-shell structure: Prepare aluminum salt complex solution A with aluminum ion concentrations of 0.015mol / L and 0.150mol...

Embodiment 2

[0072] A preparation method of a lithium-ion battery cathode material precursor with a core-shell structure, comprising the following steps:

[0073] (1) Preparation of the inner core: prepare a nickel-cobalt mixed salt solution with a molar concentration ratio of nickel sulfate and cobalt sulfate of 8:2, wherein the total concentration of nickel and cobalt ions is 1.0mol / L; prepare 18wt% ammonia water, 8mol / L Sodium hydroxide solution, with ammonia water as complexing agent and NaOH as precipitating agent. The nickel-cobalt mixed salt solution was added to the reactor at a rate of 150 L / h with a metering pump, and ammonia water was added to the reactor at a rate of 12 L / h for coprecipitation reaction. The reaction temperature is 65°C, the pH value is controlled at 11.2, and the reaction is carried out for 10 hours to obtain the inner core, namely [Ni(OH) 2 ] 0.8 ·[Co(OH) 2 ] 0.2 ;

[0074] (2) Formation of core-shell structure: Prepare aluminum salt complex solution A wi...

Embodiment 3

[0084] A preparation method of a lithium-ion battery cathode material precursor with a core-shell structure, comprising the following steps:

[0085] (1) Preparation of the inner core: prepare a nickel-cobalt mixed salt solution with a molar concentration ratio of nickel sulfate and cobalt sulfate of 8.5:1.5, wherein the total concentration of nickel and cobalt ions is 1.5mol / L; prepare 19wt% ammonia water, 8mol / L The sodium hydroxide solution, with ammonia as a complexing agent, NaOH as a precipitant, the nickel-cobalt mixed salt solution is added to the reactor at a rate of 180L / h with a metering pump, and ammonia is added to the reactor at a rate of 18L / h. Co-precipitation reaction, the reaction temperature is 60 ° C, the pH value is controlled at 10.85, and the reaction is 9 hours to obtain the inner core, that is, [Ni(OH) 2 ] 0.85 ·[Co(OH) 2 ] 0.15 ;

[0086] (2) Formation of core-shell structure: prepare aluminum salt complex solution A with aluminum ion concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com