A light-emitting device, its manufacturing method, and display device

A light-emitting device, quantum dot light-emitting technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, light-emitting materials, etc., can solve problems such as increased energy consumption of devices, weakened light emission, and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

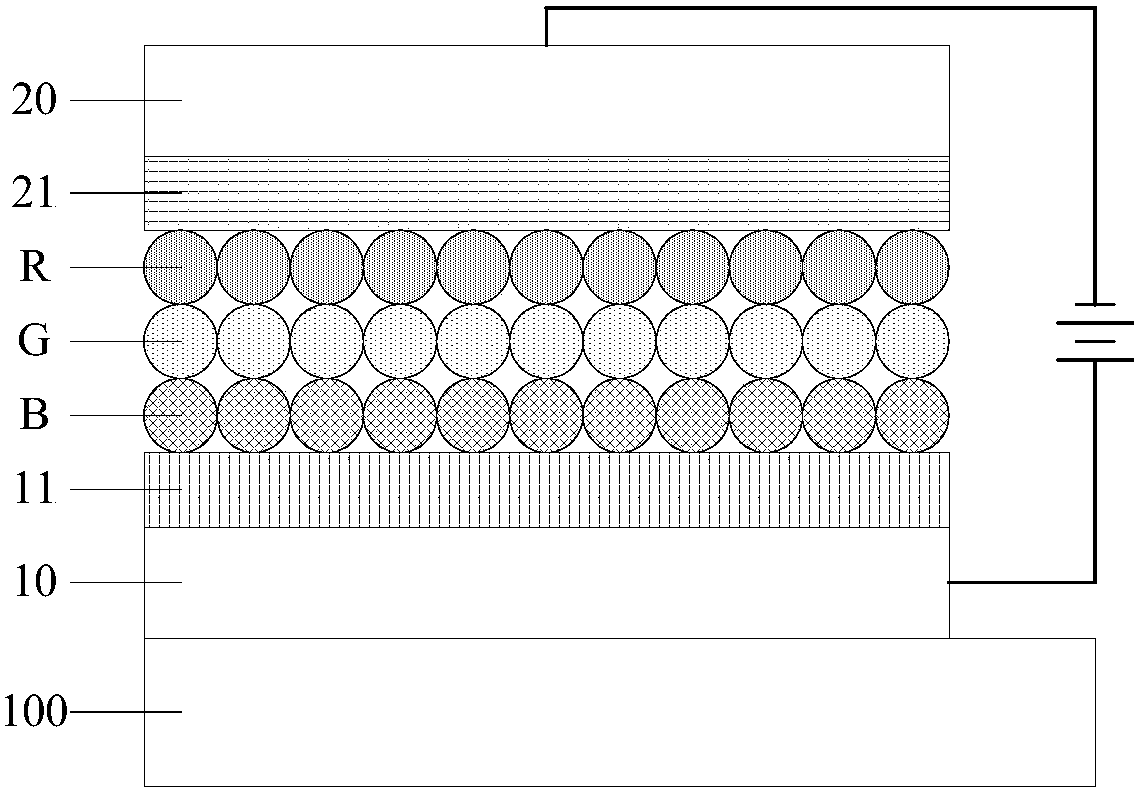

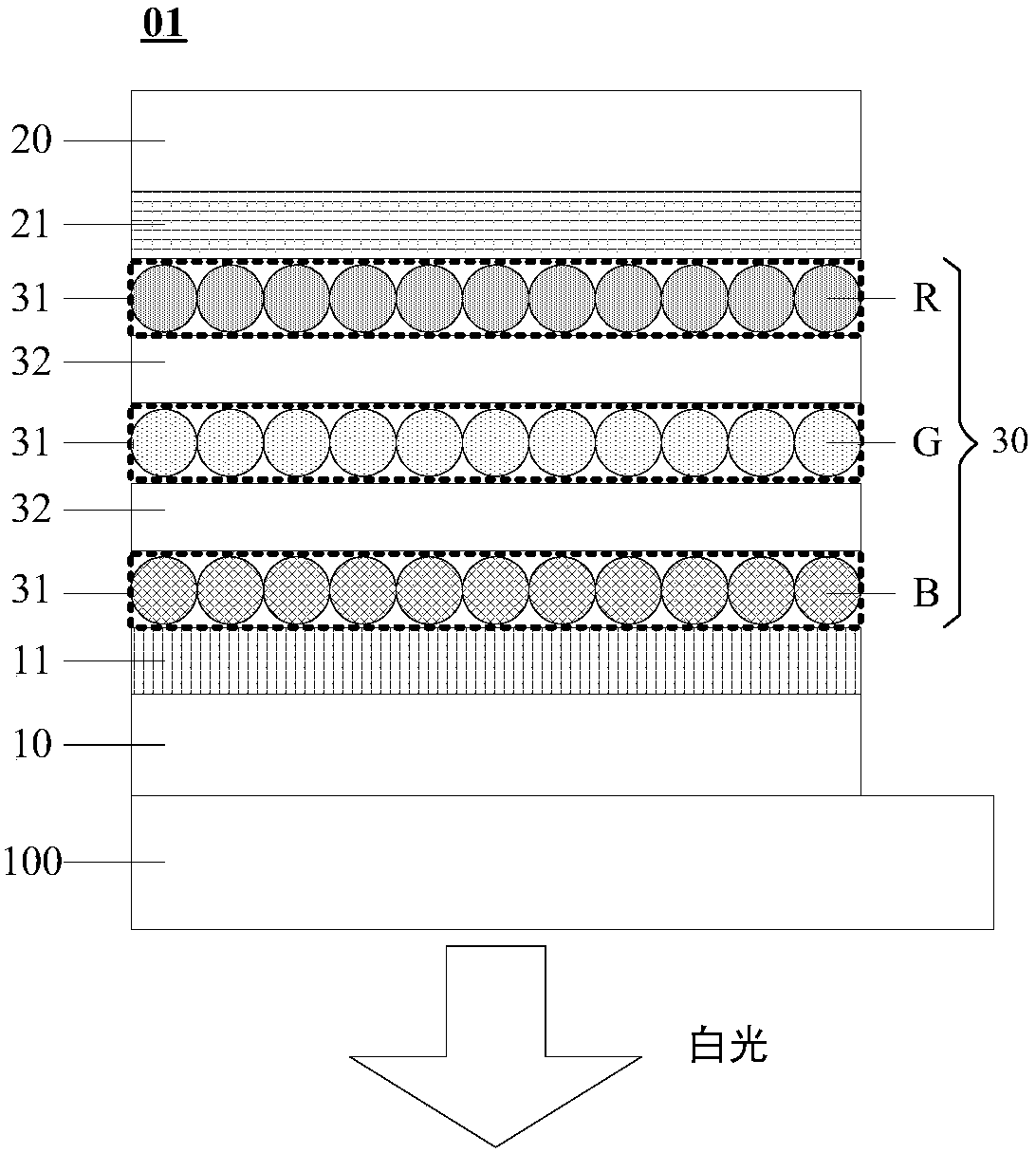

[0063] On the basis of the above, an embodiment of the present invention also provides a method for preparing the above-mentioned light-emitting device 01, the preparation method comprising: forming an anode 10, a hole transport layer 11, a light-emitting functional layer 30, and an electron transport layer 21 arranged in layers in sequence and cathode 20; wherein, the step of forming the above-mentioned luminescent functional layer 30 includes: forming at least two quantum dot luminescent layers 31 that emit light of different colors; and forming a transparent insulating layer between any adjacent two layers of quantum dot luminescent layers 31 Layer 32.

[0064] Here, the aforementioned quantum dot light-emitting layer 31 can be formed by any method of spin coating, microcontact printing, inkjet printing, and roll-to-roll printing.

[0065] Wherein, when the light-emitting device 01 is a vertical light-emitting device, that is, the anode 10 is directly formed on the substrat...

specific Embodiment 1

[0076] Embodiment 1 of the present invention provides a kind of Figure 4 The preparation method of the positive white light QLED shown, the specific steps of the preparation method are as follows:

[0077] Step S101, preparing the anode 10 on the base substrate 100;

[0078] A layer of ITO is deposited on the transparent glass substrate 100 by magnetron sputtering as a transparent anode (transmittance close to 90%), and its thickness ranges from 70 to 150 nm. Treat it with an appropriate annealing temperature to reduce its square resistance (ie, sheet resistance) to 10-40Ω / □ (the symbol "□" indicates a square).

[0079] Surface treatment is carried out to the surface of anode 10 by mechanical polishing again, so that its surface roughness Ra<2nm, Rmax<20nm; Work function (making it 4.8eV), reducing the hole injection barrier.

[0080] Step S102, forming a hole transport layer 11 on the anode 10;

[0081] The above-mentioned hole transport layer 11 can be prepared by spin ...

specific Embodiment 2

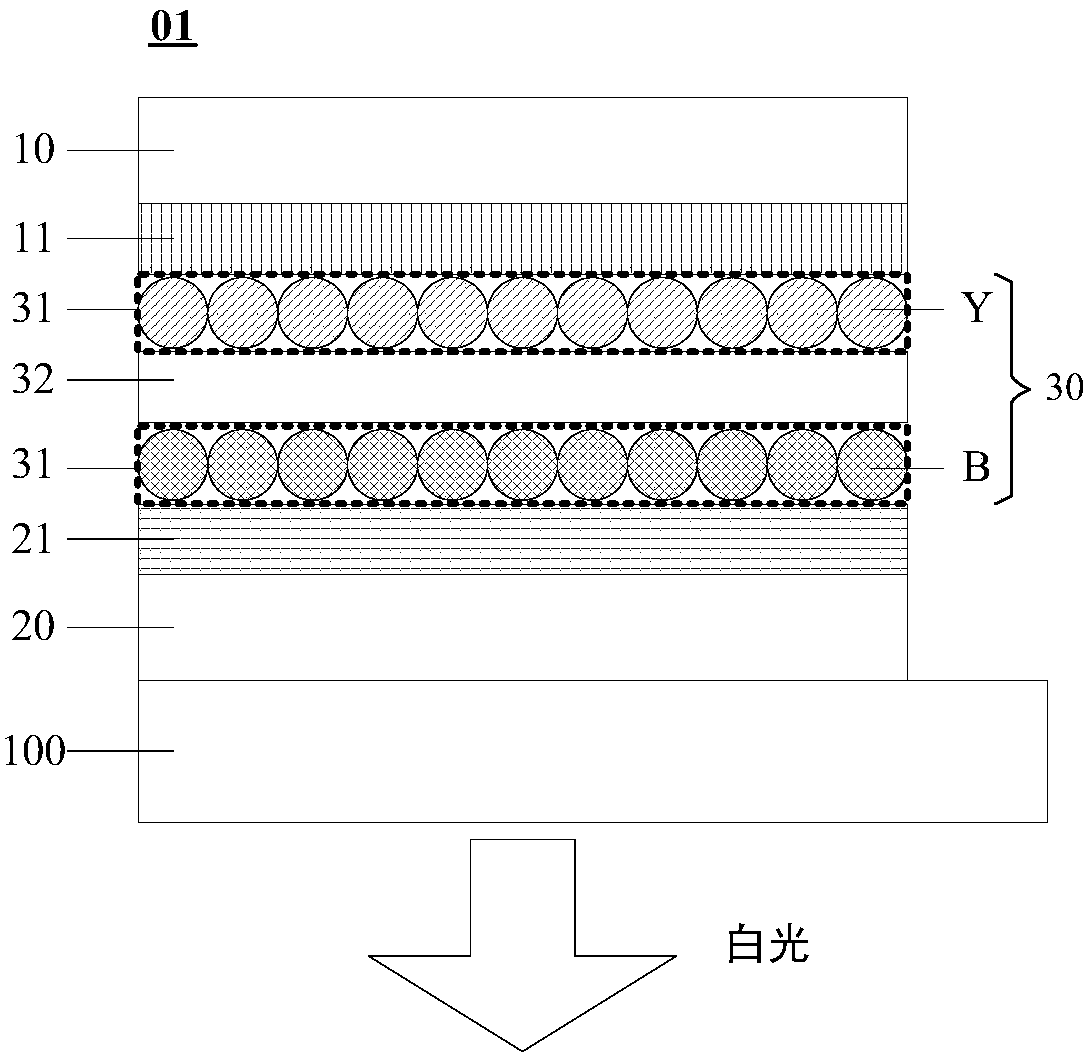

[0092] Embodiment 1 of the present invention provides a kind of Figure 5 The preparation method of the inverted white light QLED shown, the specific steps of the preparation method are as follows:

[0093] Step S201, preparing the cathode 20 on the base substrate 100;

[0094] A layer of ITO is deposited on the transparent glass substrate 100 by magnetron sputtering as a transparent cathode (transmittance close to 90%), and its thickness ranges from 70 to 150 nm. Treat it with an appropriate annealing temperature to reduce its square resistance to 10-40Ω / □.

[0095]Then the anode 10 surface is surface treated by mechanical polishing, so that its surface roughness Ra<2nm, Rmax<20nm; The work function reduces the electron injection barrier.

[0096] Step S202, forming an electron transport layer 21 on the cathode 20;

[0097] The above-mentioned electron transport layer 21 can be prepared by spin coating, coating or inkjet printing film forming process, and its thickness ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com