Apparatus for the plasma treatment of surfaces and a method for treating surfaces with plasma

A technology of plasma and gas, applied in the bonding method of surface pretreatment, the device of coating liquid on the surface, plasma, etc., can solve the problems of material erosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

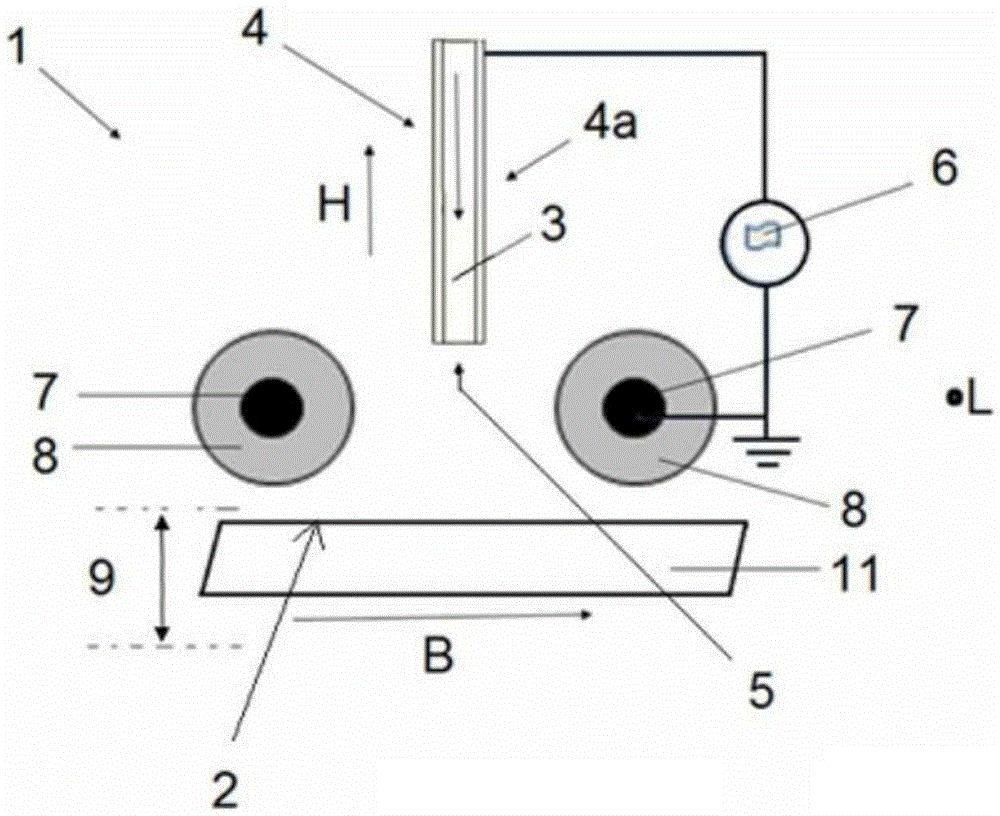

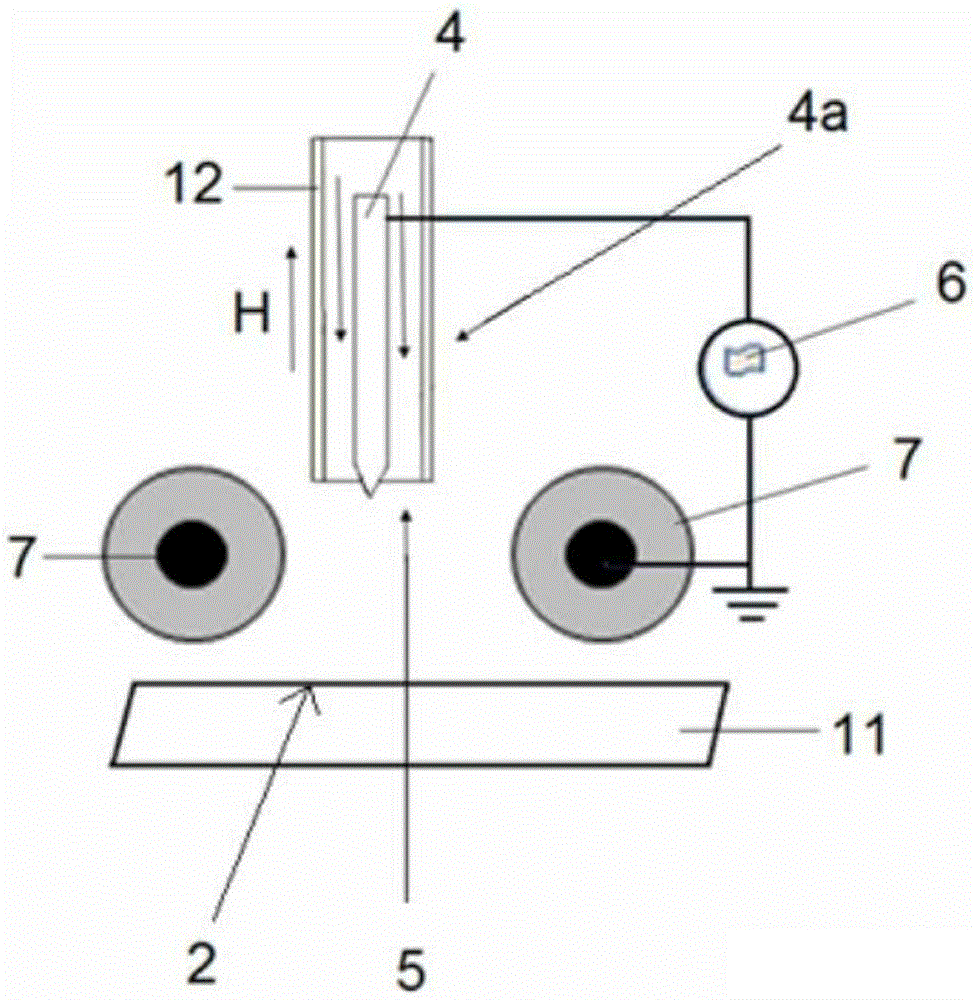

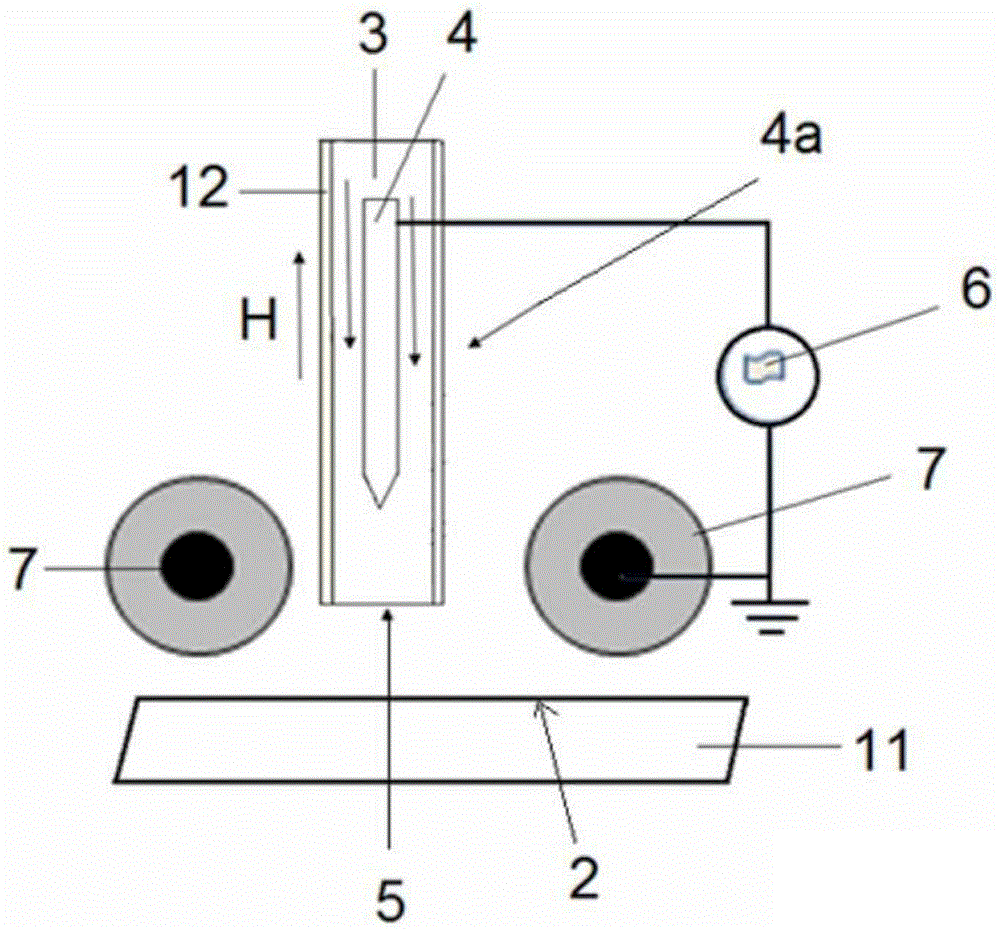

[0049] A schematic representation of a device 1 according to the invention for the plasma treatment of a surface 2 is shown in figure 1 The first embodiment in has a first electrode 4 which is formed as a tube and forms the process gas channel 3 inside it. In this embodiment, the first electrode 4 coincides with its housing. During operation of the device, for each electrode or for each head of an electrode, the process gas is guided through the process gas channel 3 at a low flow volume of eg 10 l / min. In a flow direction aligned opposite to the direction of the height H, the process gas channel 3 ends in the outlet 5 .

[0050] exist figure 1 In , only the electrode tip 4a of the first electrode 4 is shown. The electrode tip 4 a is entirely manufactured from an electrically conductive material, such as high-grade steel, iron or copper alloy, and is connected to an alternating voltage source 6 . The alternating voltage source 6 generates an alternating or pulsed high volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com