Solvothermal preparation method for in-situ electrode

An in-situ electrode and solvothermal technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve problems such as complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, dissolve 5 mM nickel chloride in 68 mL of ethylene glycol solution, then add 25 mM thiourea, and add 2 mL of ethylene diamine after the thiourea is dissolved. After being uniformly dispersed, transfer the mixture to a 100mL hydrothermal kettle and add a piece of fluorine-doped tin oxide conductive glass with an area of 3cm*3.5cm. After the kettle is sealed, it is solvent-heated at 200°C for 6h, where the metal atoms and sulfur The atomic ratio of atoms is 1:5. The substrate is taken out, washed, and dried to obtain a translucent nickel sulfide in-situ electrode.

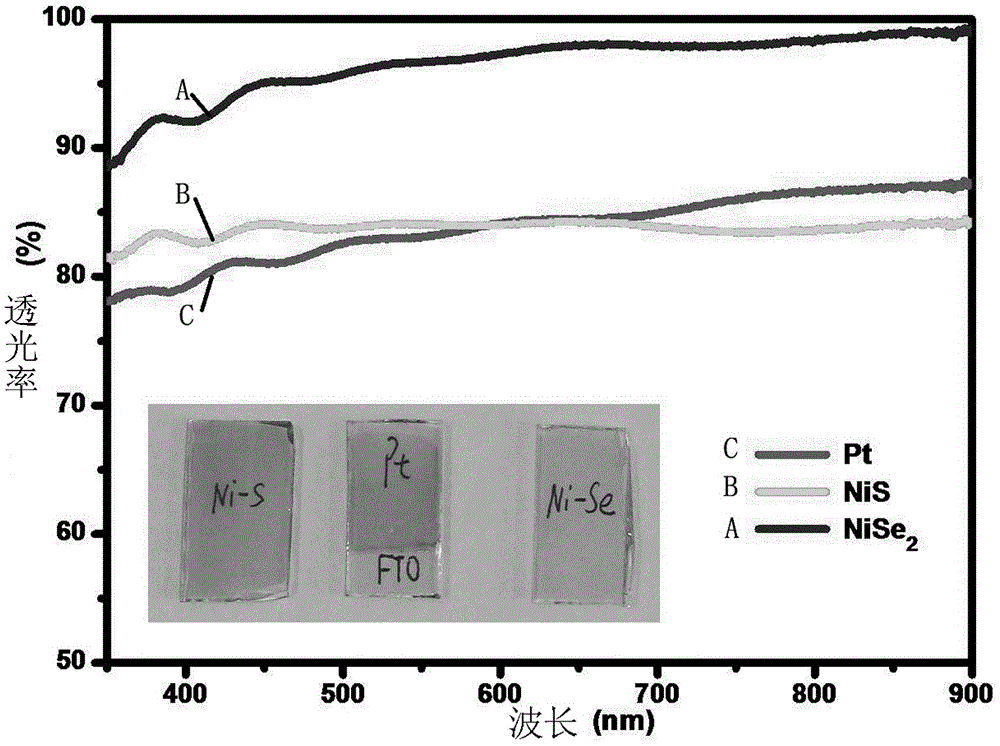

[0023] figure 1 The UV-visible light transmittance graph and digital photograph of the nickel sulfide electrode prepared in Example 1 are shown. Among them, the degree of transparency of the NiS electrode is equivalent to that of the pyrolytic Pt electrode, and the light transmittance in the ultraviolet-visible region is as high as 80% or more (not counting the light loss of the FTO glass)...

Embodiment 2

[0027] At room temperature, 5mM nickel chloride was dissolved in ethylene glycol solution, and then 5mM thiourea was added. After the thiourea is dissolved, the mixture is transferred to a hydrothermal kettle and a piece of fluorine-doped tin oxide conductive glass with an area of 3cm*3.5cm is added. After the kettle is sealed, it is solvent-heated at 200°C for 6h, where the metal atoms and sulfur The atomic ratio of atoms is 1:1. The substrate is taken out, washed and dried to obtain an opaque nickel sulfide in-situ electrode.

[0028] This example illustrates the effect of ethylenediamine additives to make electrodes transparent.

Embodiment 3

[0030] At room temperature, 3mM nickel nitrate was dissolved in the ethylene glycol solution, and then 10mM selenium powder was added and stirred for 30min. After the selenium powder was more uniformly dispersed, 1mL of ethylenediamine was added. After the ethylenediamine is uniformly dispersed, the mixture is transferred to a hydrothermal kettle and a piece of fluorine-doped tin oxide conductive glass with an area of 3cm*3.5cm is added. After the kettle is sealed, it is solvent-heated at 200℃ for 6h, where the metal atoms and The atomic ratio of selenium atoms is 1:3.33, and the completely transparent nickel selenide in-situ electrode can be obtained by taking out the substrate for cleaning and drying.

[0031] figure 1 The UV-visible light transmittance graph and digital photo of the nickel selenide electrode prepared in Example 3 are shown. Among them, NiSe 2 The transparency of the electrode is significantly higher than that of the pyrolytic Pt electrode, and is comparable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com