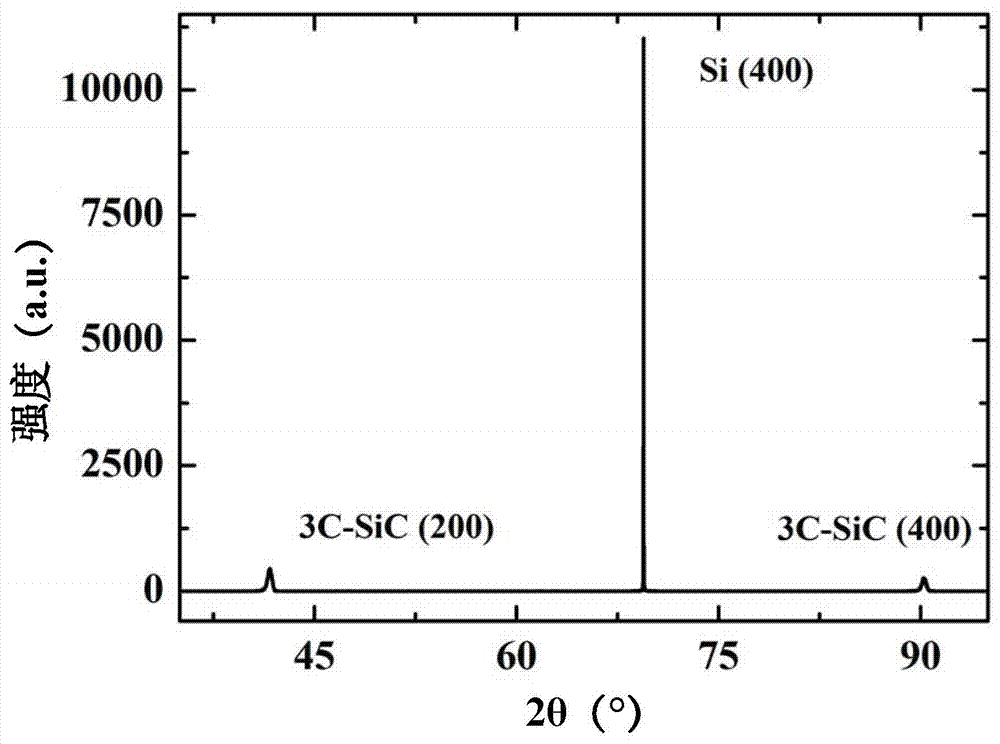

A kind of SIC-based dilute magnetic semiconductor thin film and preparation method thereof

A dilute magnetic semiconductor and thin film technology, applied in the direction of magnetic thin films, magnetic objects, magnetic materials, etc., can solve the problems of weak dilute magnetic strength of SiC materials, etc., and achieve the effect of stable and effective method, strong saturation magnetization and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

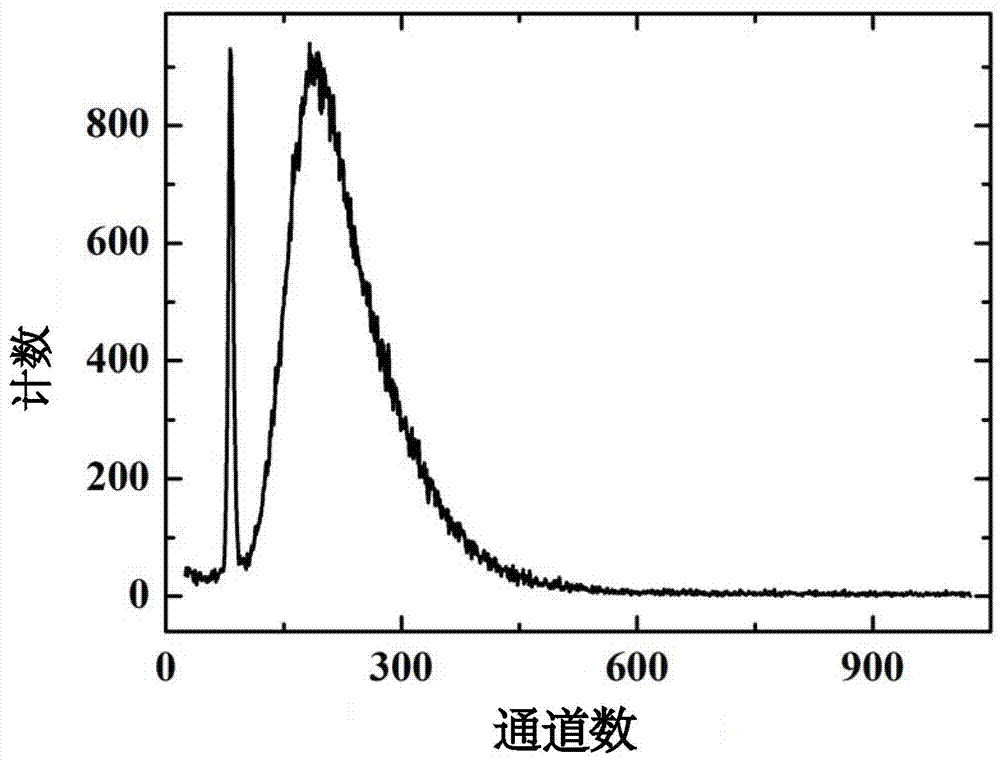

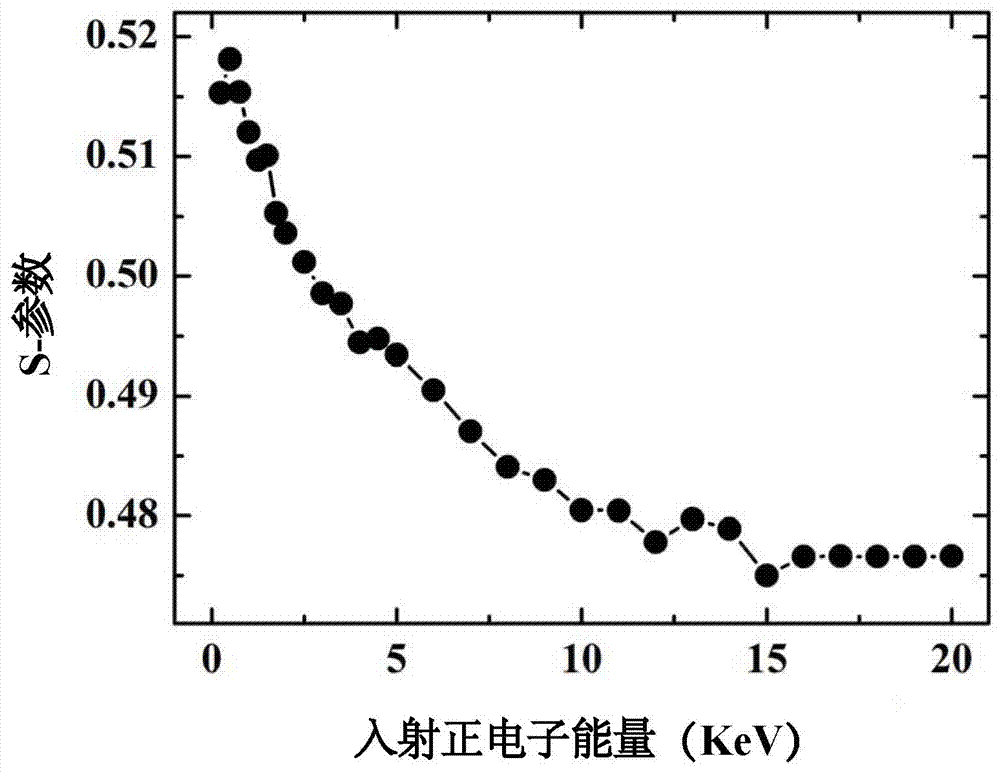

Embodiment 1

[0045] (1) Put the silicon substrate into a mixed solution of ammonia water: hydrogen peroxide: deionized water = 1:1:5 to clean for 15 minutes, and then rinse with deionized water for 10 minutes; (2) Put the silicon substrate into hydrochloric acid: hydrogen peroxide: Wash in the mixed solution of deionized water=1:1:5 for 15min, then rinse with deionized water for 10min; (3) wash the silicon substrate with high-purity N 2 Blow dry; (4) Put the silicon substrate, graphite plate, and quartz boat into the quartz cavity; (5) Pump the quartz cavity to a background vacuum of ≤5.0×10 -4 Pa, rush into 2slm hydrogen to normal pressure; (6) turn on the intermediate frequency radio frequency power supply, pass into H 2 :HCl=1:0.5% mixed gas at 1020°C for 5 minutes; (7) After the etching is completed, cut into H 2 :C 3 h 8 =1:0.045% mixed gas at 1200°C for 10 minutes; (8) After carbonization is completed, the temperature is directly raised to 1350°C, and HCl:SiH4=1:0.08%, C / Si=3.2 ga...

Embodiment 2

[0047] (1) Put the silicon substrate into a mixed solution of ammonia water: hydrogen peroxide: deionized water = 1:1:5 to clean for 15 minutes, and then rinse with deionized water for 10 minutes; (2) Put the silicon substrate into hydrochloric acid: hydrogen peroxide: Wash in the mixed solution of deionized water=1:1:5 for 15min, then rinse with deionized water for 10min; (3) wash the silicon substrate with high-purity N 2 Blow dry; (4) Put the silicon substrate, graphite plate, and quartz boat into the quartz cavity; (5) Pump the quartz cavity to a background vacuum of ≤5.0×10 -4 Pa, rush into 2slm hydrogen to normal pressure; (6) turn on the intermediate frequency radio frequency power supply, pass into H 2 :HCl=1:0.5% mixed gas at 1020°C for 5 minutes; (7) After the etching is completed, cut into H 2 :C 3 h 8 =1:0.045% mixed gas at 1200°C for 10 minutes; (8) After carbonization is completed, the temperature is directly raised to 1350°C, and HCl:SiH4=1:0.08%, C / Si=3.2 ga...

Embodiment 3

[0049] (1) Put the silicon substrate into a mixed solution of ammonia water: hydrogen peroxide: deionized water = 1:1:5 to clean for 15 minutes, and then rinse with deionized water for 10 minutes; (2) Put the silicon substrate into hydrochloric acid: hydrogen peroxide: Wash in the mixed solution of deionized water=1:1:5 for 15min, then rinse with deionized water for 10min; (3) wash the silicon substrate with high-purity N 2 Blow dry; (4) Put the silicon substrate, graphite plate, and quartz boat into the quartz cavity; (5) Pump the quartz cavity to a background vacuum of ≤5.0×10 -4 Pa, rush into 2slm hydrogen to normal pressure; (6) turn on the intermediate frequency radio frequency power supply, pass into H 2 :HCl=1:0.5% mixed gas at 1020°C for 5 minutes; (7) After the etching is completed, cut into H 2 :C 3 h 8 =1:0.045% mixed gas at 1200°C for 10 minutes; (8) After carbonization is completed, the temperature is directly raised to 1350°C, and HCl:SiH4=1:0.08%, C / Si=3.2 ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com