Anchoring system of carbon fiber reinforcement based on long-term performance

An anchoring system, long-term performance technology, applied in the direction of strength characteristics, instruments, measuring devices, etc., can solve problems such as complex procedures and operations, achieve the effects of convenient operation, improve long-term performance, and reduce cumulative fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

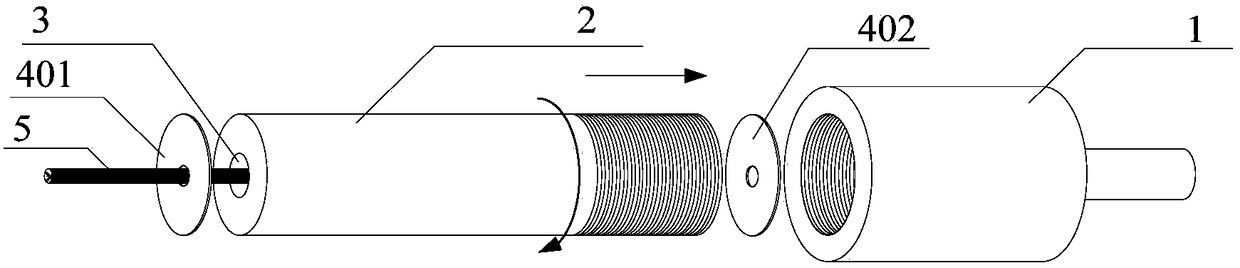

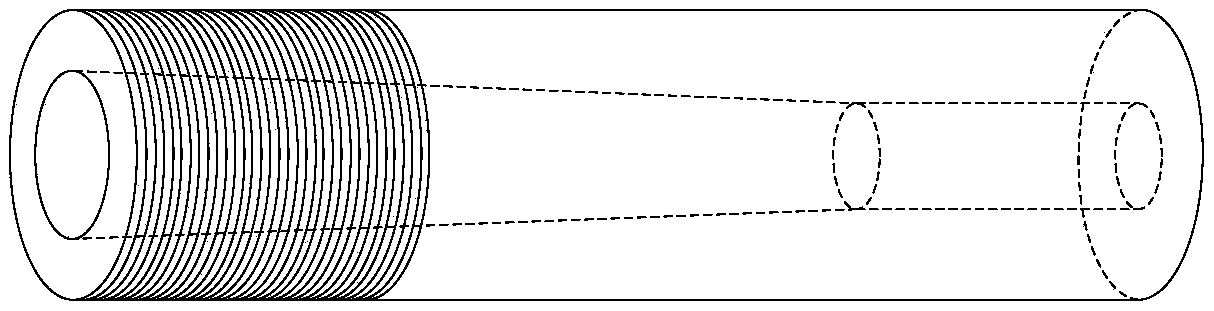

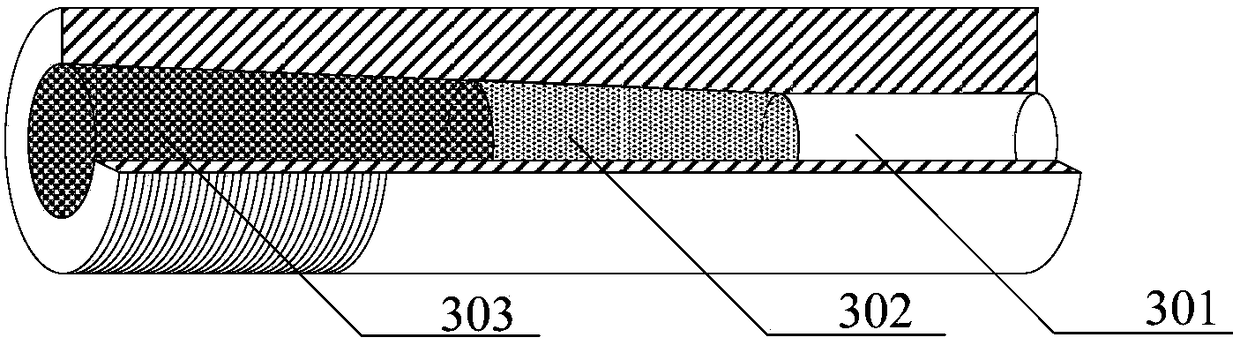

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a steel sleeve, a variable stiffness mortar binder, an end plug and a conversion head, wherein the inner wall of the steel sleeve is roughened to improve the interface between the steel sleeve and the variable stiffness mortar binder. Friction force; the steel sleeve includes a variable-section sleeve plus a straight section with no taper angle whose length does not exceed 1 / 4 of the length of the variable-section sleeve. The surface is engraved with threads. Both ends of the steel sleeve are provided with end plugs. The end plugs are copper circular sheets with a round hole in the middle. The front end plug 401 of the barrel is glued to the end of the steel sleeve. On the one hand, it prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com